Volume of recycled glass doubled

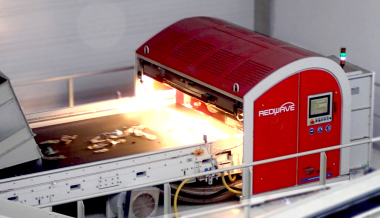

REDWAVE, one of the leader in glass recycling solutions, has supplied Australia‘s most advanced glass recycling facility, worth around 20 mio. €. Designed to process 200 000 t of recycled glass per year, this cutting-edge facility represents a significant leap forward in glass recycling technology.

The recent opening ceremony at the Laverton (Melbourne) site marked the culmination of a ground-breaking collaboration between REDWAVE and Visy, one of the leaders in glass recycling and manufacturing in Australia and New Zealand. Together they have embarked on a revolutionary project that will redefine the glass recycling in Australia. This state-of-the-art facility, equipped with the latest sorting technology, replaces the previous facility, and introduces a new era in sustainable glass management.

Wayne Russell, Executive General Manager – Recycling at Visy, emphasized the commitment to closing the loop for glass in Victoria. „At Visy, we are committed to closing the loop for glass in Victoria. By building our brand-new glass recycling facility with REDWAVE‘s world-class optical sorters, we‘ve doubled the amount of glass we can recycle,“ Russell stated.

„Our partnership with REDWAVE means we have state-of-the-art equipment supported by a trusted and reliable technology partner,“ Russell continued. As general contractor, REDWAVE was responsible for the entire process of design, engineering, delivery, installation, and commissioning, ensuring a maximum yield of cullet.

Revolutionising glass processing

With a processing capacity of 200 000 t/a, the new plant will receive two-thirds of the input from kerbside mixed recycling collections (MRF Glass) and one-third from the newly established Victorian container deposit scheme (CDS Glass). On arrival, the glass is meticulously sorted into three different colours, down to 3 mm in size. This systematic sorting ensures a reliable supply of flint (clear), amber, and green glass for future glass production. The plant also maximises the use of by-products, minimising the impact on landfill and recovering valuable secondary materials. Remarkably, the sorting operates autonomously, eliminating the need for manual sorting – a pioneering achievement in glass processing.

Innovative sensor technology REDWAVE has devised an ingenious solution to the unique challenges posed by glass-ceramics, which behave differently to ordinary glass when melted. Using its proprietary CX camera and lighting unit, the system skillfully separates glass-ceramics, ceramics, stones, porcelain, and off-colours through a multi-stage sorting process.

Increased efficiency with REDWAVE mate smart plant

The implementation of REDWAVE mate smart plant software optimises plant efficiency by collecting and processing real-time production data. This data empowers operators and enables autonomous plant operation, all tailored to meet customer requirements. At the heart of this data collection are REDWAVE‘s sorters, which act as data hubs to relay critical information to the software.

Digital sales landscape

Navigating this major plant sale during the global pandemic required innovation. REDWAVE rose to the challenge by making the entire sales process digital. With a remarkable commitment to the customer experience, all interactions, including reference visits and sorting tests, were conducted virtually, bridging distances of 16 000 km and an eight-hour time difference.

Looking to the future: follow-up order for another plant in Yatala

As proof of the success of the project, REDWAVE has already been awarded a follow-up contract for the construction of another glass recycling plant at the Yatala site near Brisbane. This pioneering project is already in full swing and is scheduled for completion in early 2025. „We are delighted that REDWAVE can make a significant contribution to diverting glass from landfill in Australia. Thanks to the outstanding sorting quality of our plant, we can now bring this glass into the recycling cycle and create new bottles,“ says REDWAVE Managing Director Silvia Schweiger-Fuchs. With the opening of this pioneering plant, REDWAVE is setting a new standard in glass recycling technology and underlining its commitment to sustainability and innovation in the industry.