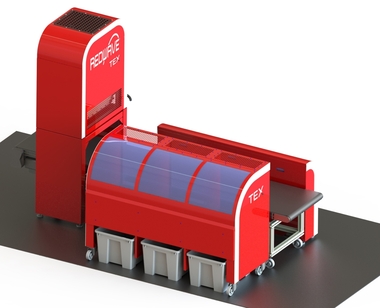

REDWAVE TEX: Intelligent sorting technology for the circular economy

6.95 million t of textile waste per year – in the EU alone. Less than 1 % of the textiles produced worldwide are recycled into new textiles. The textile recycling industry is at a turning point, driven by ambitious regulations, growing environmental awareness and innovative technologies. BT-Systems, with its REDWAVE competence centre and pioneering REDWAVE TEX technology, is actively shaping this future.

Market development and regulatory framework

The EU has set itself ambitious goals with its “Strategy for sustainable and recyclable textiles”: the separate collection of textile waste has been mandatory in all member states since 2025. Standardised regulations on extended producer responsibility are also planned. This will make manufacturers responsible for the entire life cycle of their products – from production to recycling.

These requirements increase the need for modern sorting technology that returns textile raw materials to high-quality material flows. Companies that invest in efficient systems at an early stage will secure decisive competitive advantages.

Technology for the circular economy: REDWAVE TEX

REDWAVE TEX is a sensor-based sorting technology that automatically detects and separates textiles according to material type, colour and contaminants such as buttons, zips or labels. The system has a modular design and can be flexibly adapted to individual sorting criteria and process requirements – it is available both as a single module and as a fully integrated system comprising scanner, control cabinet, analysis software, conveyor belt, discharge units and valve boxes.

The enhanced REDWAVE TEX 2i sorting system now enables precise sorting of clippings – both in the traditional sense of textile offcuts from production, and as non-textile attachments such as logos, labels or decorative elements found on used garments. Both forms have long posed challenges for high-quality textile recycling. By reliably identifying and separating these materials, the system significantly increases fraction purity and improves the overall recyclability of post-consumer and pre-consumer textiles.

Since its presentation at IFAT 2024, REDWAVE TEX has been continuously developed – both mechanically and in terms of software. The result is a versatile portfolio for a wide range of requirements:

REDWAVE TEX 2i solution: For high mass throughput with few sorting criteria – ideal for shredded textiles.

REDWAVE TEX system: For simultaneous sorting into numerous target fractions – ideal for whole garments or re-use concepts.

REDWAVE Analyser: For monitoring and quality control directly on the conveyor belt.

Flexibility and innovation as a competitive advantage

BT-Systems does not rely on rigid standards, but on flexible, future-orientated solutions. Customised sorting solutions are developed in close cooperation with customers – for example by integrating customer-specific sensor data into the sorting processes. This results in intelligent, data-based processes that are precise, efficient and future-proof from a regulatory perspective. Feasibility analyses and continuous optimisation result in practical systems that meet the increasing demands of the industry.

BT-Systems presented REDWAVE TEX at the Textile Recycling Expo in Brussels at the beginning of June 2025. As a founding exhibitor, the company provided insights into the latest technological developments and invited trade visitors, decision-makers and research institutions to exchange ideas. Visitors learnt how REDWAVE TEX is paving the way for a sustainable, circular textile economy – efficient, flexible and future-oriented.