Second Doppelmayr RopeCon® system at Lenzing AG

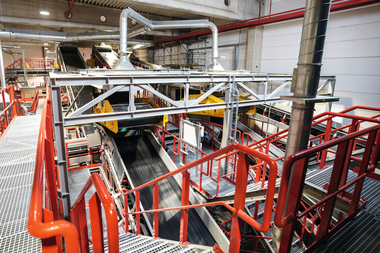

For the planned expansion of wood chip transport between the storage area and the digester house at their cellulose processing plant, Lenzing AG, a leading company in the field of the production of fibers made from the raw material wood, contracted a second RopeCon® conveying system to ensure sustainable raw material supply. The system has to cover a length of roughly 630 m between wood storage area and digester house, passing right across the existing plant infrastructure. In addition, the system had to guarantee high availability in order to allow optimal integration into the production process and reliably deliver the 350 t/h to their destination.

The second RopeCon® installation has been built to run alongside the existing RopeCon®, which has been transporting beech wood chips since 2003. In the time since then, the system has proved to be a reliable and efficient solution for supplying the digester house. As the system is raised off the ground, it makes light work of crossing the existing infrastructure on the premises.

Like the first RopeCon® at the Lenzing plant, the second installation also impresses with high availability, wind stability and its ability to cross high-density plant infrastructure without any problem. As a consequence, the RopeCon® creates an optimal link between the raw materials storage facility and the production process.

www.doppelmayr-mts.com