Metal recycling history in Colne Valley since 1876

The Schofield family‘s scrap yard is unique in Great Britain, not only because of its idyllic location on a hill near Huddersfield/Yorkshire but also the material and how it is processed here deserve a closer look.

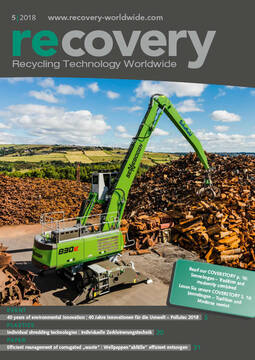

The sixth generation of the family business Schofield of Huddersfield/Great Britain, is closely rooted in the subject of recycling. The history even goes back to the early 19th century, long before everyone was talking about recycling and the use of raw materials, the founder James Schofield had established a family tradition at the site with the recycling of waste from the wool industry. More than 140 years later, Schofield Metal Recyclers is still worth a visit, after all, Managing Director Mark Schofield focuses on „highest quality instead of mass production“. That is why the company‘s machine and vehicle fleet is always at the cutting edge of technology. In mid-2018, sales and service partner Hassell was able to deliver a SENNEBOGEN 825 E and 830 E each.

Highest quality instead of mass production

Located between Leeds/Bradford and Oldham/Manchester, material is collected and purchased within a 100 mile radius. Mark Schofield and his ancestors have specialized in the processing of high-quality casting materials. „We can break cast elements weighing up to 15 tons here on site with our drop balls, which requires not only skill, but also extremely robust and powerful machines,“ explains Mark Schofield. For 20 years, he has relied on the green SENNEBOGEN material handlers made in Germany.

Modern material handlers are faster, more efficient and above all safer

Equipped with the modern Maxcab comfort cab, which can be elevated by 2.70 m, the drivers not only have an excellent view of their working environment, but also work reliably and are protected in all weathers. The SENNEBOGEN 830 E also has a powerful 164 kW diesel engine and a maximum range of 17 m. This allows them to stack up even the heaviest of materials safely to maximum hight. The high reliability of the machine and all components, the good stability and finally simple maintenance are features that are particularly appreciated here on SENNEBOGEN machines. Added to this is the industry knowledge and good support from the sales and service partner Hassells from Stoke-on-Trent.

„While a lot used to be done with rope-operated cranes, today modern material handlers are faster, more efficient and above all safer,“ explains Mark Schofield. Only through the continuous modernization of space and equipment has the company been able to successfully assert itself on the market over the decades with a focus on the highest quality in processes and materials. Until about ten years ago the scrap market for Schofield’s, both buyers and sellers, was predominantly in the UK, today up to 60 % of buyers are from abroad, although the iron foundries in the region also remained indispensable customers, according to Schofield. For this reason, the stock on the site can never be large enough to safely fulfill any order, no matter how large.

//www.sennebogen.de" target="_blank" >www.sennebogen.de:www.sennebogen.de