Lindner’s mobile shredders and system solutions

The Lindner twin-shaft shredders from the Urraco and Miura series are based on the principles of maximum flexibility and customisation. “Our customers require solutions that deliver results specifically tailored to their particle size, fines and throughput needs. In recent years, we have focused in particular on optimising the hydraulic systems and control software, as well as expanding the range of shafts. This enables us to customise the shredders to the client’s specific requirements, allowing us to shred waste wood to a P100 fraction according to ISO 17225-1, for example. With a downstream star screen, we are even able to produce a P63 fraction with a fines content of less than 5 %. If we change the configuration, we can use the same tried-and-tested machine as a volume reducer for light scrap. The mobile hydraulics jointly developed with Bosch-Rexroth ensure that the machine always runs at the optimum operating point, saving up to 30 % on fuel compared with conventional solutions. This is exactly what we want to demonstrate at this year’s RecyclingAKTIV in Karlsruhe,” says Thomas Huber, Product Manager at Lindner-Recyclingtech.

Wood and biomass demo: Lindner Urraco 75 DK and Zeta Star 75 F2 DK

Combining a Urraco 75 DK shredder with an economical Stage V diesel engine and a Zeta Star 75 F2 DK star screen as a mobile solution delivers a clean P63 fraction with a throughput of up to 25 t/h. The perfectly matched shredder and screen make this the go-to systems solution to produce ideal particles without any costly additional separation of a third fraction. No precious raw materials lost while always operating at optimum efficiency.

With the variable star speed and the hydraulically adjustable screen deck angle, this system can be adapted to varying input qualities at the touch of a button while yielding precise and classifiable output at all times. In addition, the hydraulic adjustability of the return conveyor ensures minimum handling effort. Alternatively, oversized particles from the first shredding stage can be separated as a second final fraction.

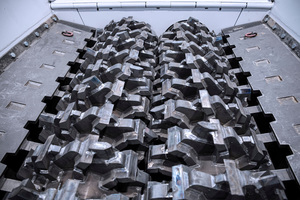

Scrap & metal demo: Lindner Urraco 95 DK

When processing light scrap such as scrap or sheet metal, aluminium or WEEE, it all comes down to the quality of the shredding unit because metals are particularly robust and abrasive. Lindner’s optimised chopping boxes, high-quality hard-faced shafts and well-engineered robust drive ensure a long service life and maximum productivity. With 90 % of the output optimally shredded to < 300 mm for downstream sorting, the powerful Urraco 95 DK produces up to 40 t/h.

Stand: F124