Collection campaign for closed-loop recycling

of film packaging

HAVER & BOECKER‘s customers also have a valuable opportunity to recycle plastic packaging material. With the ADAMS® technology, they fill powdered products into PE bags. And for good reason: the packaged product is best protected in this way until it gets used by the end customer.

The film bags are made of mono-material. Unlike a yogurt cup, where it is necessary to separate plastic containers from the aluminum lid, an ADAMS® bag consists of only one directly recyclable material. Moreover, the ADAMS® bags can be completely emptied of residue and are therefore particularly suitable for recycling. How can this packaging material be returned to the recycling loop as a valuable material?

The question was whether it would be possible to collect the film bags filled with the ADAMS® systems as a recyclable material. HAVER & BOECKER started an experiment and showed that it is possible! A total of 15 t of plastic scrap were collected, then processed by Berry Global at its Steinfeld plant and reused to produce new film bags.

Plastic has a negative reputation that is partly unjustified. If plastic is used as a purely disposable product, it has negative consequences. Issues such as improper disposal or pollution of the oceans are publicly discussed. In order to fully utilize the advantages of PE, the material must be returned to the recycling loop.

Plastic packaging is a functional way to safely protect products. It is a valuable material that, in the best case, gets reused:

- Thermal use: it is burned and the energy is used.

- Chemical recycling: oil can be extracted from the material using modern processes.

- Material recycling: it is processed into recyclate and, depending on the quality of the material, used in the production of new films.

The collection campaign

The film bags can be emptied of residue and thus are easily recyclable. In theory, this is clear to everyone. A look in practise shows that film packaging is definitely collected and disposed of in a targeted manner. The residual waste container is the most expensive disposal. The realization that films are recyclable materials is steadily increasing.

The estimation of HAVER & BOECKER: 1/3 of the end-customers dispose in an exemplary manner, 1/3 could be motivated to do so, 1/3 is rather difficult to convince. With the collection campaign the company aimed to set an example here. It was time to show how the film scrap can be collected and how new packaging can be created from an old one. This is how HAVER & BOECKER wanted to raise awareness of the fact that film is a valuable material and that it is worthwhile to bring it into a cycle.

All machines are pre-set at the factory before being shipped to the customer and go through a test run for final approval. This step produces a lot of film scrap that is no longer used and is usually disposed of in the usual way. HAVER & BOECKER has initiated a recycling process for its film products with the film manufacturer Berry Global, one of the company’s long-standing partners. This was the basis for the possibility of collecting the film scrap and having it further processed.

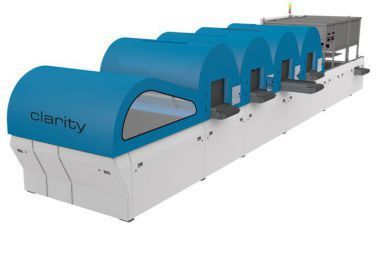

The ADAMS® technology

With the ADAMS® technology, customers of HAVER & BOECKER fill powdered products into PE bags. This is a sustainable solution because bags filled with the ADAMS® technology are made of mono-material, are tear-resistant, long-lasting, re-sealable, easy to empty and 100 % recyclable. The packaged product is thus best protected from the elements. From the filling of the product, to storage, to transport and finally to the end customer for the point of use, no costly manufactured product gets lost.

The reduction of material loss is the decisive and sustainable element: the CO2 footprint for 25 kg of cement alone, for example, is approx. 14 250 g in Germany (this corresponds to 570 kg CO2 e/t of cement). For every single cement bag that does not „fall by the wayside“, the use of plastic bags has been worthwhile. The more a valuable product actually gets used, the fewer resources that get wasted. That alone is sustainable and resource-saving.

The environmental group Deutsche Umwelthilfe (German Environmental Aid) has given it to HAVER & BOECKER in writing: „In principle, reusable bags would most likely be the most environmentally friendly solution here. When new bags are delivered, the emptied bags could simply be taken away again and then refilled. If this were not possible, it would be important to pay attention to recyclability and a high level of recycled material content in the bags. Composite materials are therefore, in our estimation, rather less suitable. [...] in our opinion, the pure PE bag is the best option if reusability is not possible. In addition, attention should be paid to the lowest possible material use and large filling sizes.“

Customers of HAVER & BOECKER are convinced of the advantages. In the meantime, more than 200 ADAMS® systems around the world fill carefully manufactured powder products, day after day. In 2014, HAVER & BOECKER even won the Sustainability Award from Lafarge with the ADAMS®, in particular because of the sustainable packaging. Nevertheless, the company, the customers and also the intermediaries are confronted again and again with the thoroughly negative image of plastic. So the same applies here: The material must be returned to the recycling loop.

Implementing the scrap film collection campaign

All the colleagues involved immediately understood it made sense to collect this recyclable material to collect it in mesh boxes. After a few months, a huge mountain of plastic sections had been generated and loaded onto a tractor-trailer. With 15 tons of scrap material, the driver set off for the film manufacturer Berry Global.

Once there, the film scrap was washed, shredded and processed into regranulate. Then, with the addition of 50 % virgin material, a new tubular film was produced for use with the ADAMS® lines. The result: A high-quality new bag made from 50 % recyclate for packing powdered bulk materials. HAVER & BOECKER had closed the loop with the collection campaign and shown that collecting and recycling can be so simple and that film is a sustainable form of packaging that is fit for the future.

Fit for the future

HAVER & BOECKER is optimistic about the future. With the collection campaign, the company wanted to raise awareness that film packaging is a valuable resource. Recycling companies gratefully accept this valuable material. Recycling is increasingly becoming a prospect. Large and successful retail groups even see this as a strategic addition.

This trend can also be observed in the building materials industry.

For example, Heidelberg Materials, a leading building materials manufacturer, announced the acquisition of a Berlin-based building materials recycling company at the end of November, 2022, in order to „significantly strengthen activities relating to the circular economy,“ according to a statement. This was followed in mid-December by the announcement of the acquisition of a leading recycling and building materials company in the UK.

Recycling companies everywhere are expanding their capacities, and technology is getting better and more accurate, making sorting and recycling even easier and increasingly possible. On the other hand, waste disposal will not become cheaper in the coming years.

The legal framework is also setting the direction: The „Green New Deal“ presented by the European Commission, including the Circular Economy Action Plan must be implemented. Recycling rates for all packaging will be increased and will continue to increase. Following the plastic levy introduced in the EU in January 2021, member states must now pay 80 cents per kilogram of non-recycled plastic packaging waste to the European Union. Product manufacturers must therefore think about optimizing their packaging and pay special attention to recycling processes and rules. As a partner, HAVER & BOECKER is ready to make its contribution.

Authors:

Silvia Benneker und Christian Reinke, HAVER & BOECKER