Austropressen – with intelligent technology for sustainability and conservation of resources with synthetic materials

Current customer projects with customised solutions such as for Vöslauer Mineralwasser GmbH, Austria, and Retour Matras BV, the Netherlands, clearly demonstrate Austropressen’s successful implementation of recycling and reuse.

Customer story: Retour Matras BV, Zeeland/the Netherlands

Foam material presses for efficient mattress recycling

The retail sector regards Retour Matras as the Dutch mattress recycling specialist. The company collects, shreds, separates and transports the individual materials. The materials are sorted by foam, latex and textile cover, compressed into transportable bales in presses and sold to recycling companies for reprocessing.

The challenge: Compaction, transportation, processing

Retour Matras BV requires baling presses to optimally prepare and bundle the different materials for transportation. In terms of conveyance, filling and binding the bales, high throughput, trouble-free operation and maximum automation are essential requirements.

The solution: Individually customized, top-performance and user-friendly

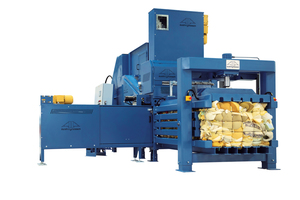

Retour Matras are using two types of Austropressen models for material compaction: the semi-automatic AP-42F and the fully automatic APK-F60.

Both are designed to handle foam and expanding materials and offer high throughput rates, high bale weights, speed and continuity to meet all company requirements. Both Austropressen models feature a user-friendly display showing:

Flow chart (of pressing process)

Information and technical data for operators (fill level, oil temperature etc.)

Error messages with notes for remedy, tips etc.

The AP42F-1400 works with automatic filling and compaction in the direction of pressing, 22 kW drive for 420 kN pressure force:

The large filling hopper allows for high throughput and large bale sizes (1000 x 70 0 x 1300 mm) and bale weights of approx. 400 kg (depending on material)

Message on the display indicates that bales are ready for manual binding. The binding process with simple Quick-Link wire systems for speed: 8-fold in cross binding (3 x horizontal and 5 x vertical)

Finished bales with ideal dimensions for container transport are automatically ejected

The fully automatic APK-F60 features a 22 kW drive for 600 kN pressure force, producing 1100 x 750 x 1200 mm bale sizes. The reinforced system with retaining claws ensures free filling space and reliable PLC control guarantees trouble-free continuous operation. The Austropressen Drillfix automatic wire tying system will use 9-fold cross binding (4 x horizontal and 5 x vertical) to perfectly wrap each bale. Depending on material, bale weights up to 450 kg will be achieved. High stability and optimal bale shape will allow up to three bales of stacking height. This guarantees maximum utilisation of truck and container transport capacities.