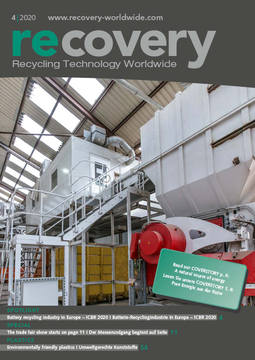

A complete waste wood processing system for a biomass heat & power plant

Biomass is a very attractive resource for sustainable energy production. Besides being ideal for generating electricity, it can also provide an efficient source of heat. R Plevin & Sons Ltd., one of the largest wood recyclers in the United Kingdom, processes up to 150 000 tonnes of waste wood per year at its site in Hazlehead/England, supplying fuel to a biomass heat & power plant of a major energy company. Vecoplan AG planned and built the entire system and commissioned it in a very short time. The heart of the system is a highly efficient Vecoplan VNZ250 XL/T shredder.

At its site in nearby Hazlehead, Plevin processes up to 150 000 tonnes of waste wood per year. “We have one of the most productive waste-wood recycling systems in England,” says the company’s engineering manager. “To ensure safe, efficient operation of the power plant, the fuel we supply has to meet high standards for purity and degree of shredding.” This puts high demands on the recycling system. The incoming waste wood is derived from a variety of sources and disposal areas, and it contains metallic and non-metallic impurities. The fuel must comply in size with the P63 specification, and the fraction of fines must be as low as possible.

Everything from a single source

This high-performance system was planned, delivered and installed from a single source: Vecoplan AG. The company, which is based in Bad Marienberg/Germany, develops and manufactures machines and plants for the resource and recycling industry. “Our tasks encompass services like planning, consulting, integrated project management, comprehensive service, installation, commissioning and maintenance,” explains Paul Costello, Vecoplan’s Regional Sales Manager, who is responsible for Plevin. Vecoplan provided solutions for the waste wood processing line from end to end, including loading, conveying, separation of impurities and shredding. “We coordinated all of the components for maximum performance, efficiency and output quality,” says Paul Costello. The result is a plant with a capacity of up to 80 tonnes per hour.

Safe and reliable process

Trucks deliver various kinds of waste wood mixed with impurities to the plant. Wheel loaders feed the pre-crushed wood to drag chain dischargers which move it to the discharge side, dose it and transfer it to the next stage, the conveyor system. This consists of trough conveyors installed by Vecoplan. The material passes a powerful over-belt magnet which removes all ferrous materials. Non-ferrous metals like aluminium, copper and brass are taken out further downstream by eddy-current separators. A disc screen then removes items longer than 80 mm from the material flow so that they can be conveyed to a shredder. “For this processing stage we supplied a re-shredder from our VNZ 250 XL/T series,” says Paul.

Besides having extensive experience with sophisticated, future-proof solutions for the wood industry, Vecoplan is an expert in its core speciality: shredding. “When energy recovery is the primary concern, efficient shredding of the input material is the key to success in processing and utilisation,” explains Paul. “With the VNZ 250 XL/T, customers can satisfy all of their requirements for purity and degree of shredding, whilst ensuring minimal fines production.”

Vecoplan developed this double-shaft re-shredder for processing pre-shredded waste wood and other materials. Its two solid steel rotors, each 640 mm in diameter, deliver optimum performance. To protect the shredder against damage from impurities, it is equipped with a pneumatically tensioned counter knife called a flipper. “The re-shredder gives customers a much smaller percentage of fines than with ordinary shredders,” says Paul Costello. This advantage comes from the slow-running rotors, which typically run at only 160 rpm. Rather than crushing the material like conventional high-speed shredders or hammer mills, it uses slow speed and high torque to cut the material to the required size. The rotors are each driven by Vecoplan’s patented HiTorc drive. A controller integrated in the frequency converter ensures that an optimum torque is applied to the rotor shaft at all times and in all operating conditions. This makes the HiTorc extremely energy-efficient. “Users can achieve savings of up to 40 % in electric consumption compared with conventional drives,” says Paul Costello. And since this purely electrical solution requires no clutches, hydraulic drives or flywheels, maintenance costs are significantly reduced.

In the next step, the material passes through oscillating screens to separate fines, mineral matter and oversize from the finished fuel. Drag chain conveyors deliver the fines to a fully automated twin truck-loading station; oversize back to the re-shredder and the finished fuel to a truck loading area ready for delivery to the power plant. Vecoplan also installed a sorting cabin in which workers remove large non-metallic objects and film from the oversize screenings.

Perfect combination of components

“By individually combining high-quality components, we have ensured that the plant operates efficiently and safely,“ says Paul Costello. “We dimensioned all the components of the processing line to match material intake cycles and fuel requirements.”

Plevin’s engineering manager is highly impressed with the shredding equipment and the HiTorc drive. “The slow-running VNZ 2500 re-shredder is what ensures minimum fines.” He is also pleased with the drive, which makes the shredder very efficient and has a lot more power than is needed at present – and that bodes well for the company’s future.