119 000 € of DBU funding for fertiliser recovery process

Phosphorus in the form of phosphate promotes plant growth and frequently forms the basis for fertilisers. Extraction of the mineral substance harbours numerous problems, however, making the around two million tonnes of sewage treatment sludge which occur annually in Germany and contain recyclable phosphorus an important source.

Two steps from sewage sludge ash to fertiliser

Drying of all the sewage treatment sludge yielded in Germany would result in its weight being around two million tonnes each year - and of this, around 60 000 t would be phosphorus, the substance vital for all organisms. “Currently, however, less than half of the sewage treatment sludge and its valuable content substances is actually utilised. Our process aims to change that”, comments project manager Dr. Lars Leidolph, of Glatt Ingenieurtechnik. In the process developed by his company, ready-to-use standard fertiliser is produced in two main process operations from the ash of incinerated sewage treatment sludge. Phosphoric acid is firstly added to the ash, dissolve the phosphate in the ash. Without this step, the nutrients contained in the ash could not be absorbed by plants. Reaction of the minerals with the acid generates phosphates which are available to plant life and are therefore of interest to the fertiliser industry. If necessary, further nutrients in liquid and/or solid form, or additional phosphate sources, can be added to the mixture of solids and liquid (suspension). In addition, the process is also suitable for multiple ash types. The suspension is then dried and granulated, resulting in a phosphate fertiliser end product. “The fertiliser produced in this way conforms to legal requirements and can be immediately used in agriculture,” Leidolph continues.

Two-stage process solves previous problems

Simple technological implementability is claimed as an important benefit of this process. In addition, this method requires no raw phosphate and less energy, and produces no waste. As Hempel adds: “The basic concept of this process was actually tested long ago, but certain technical problems have prevented its practical use until now”. Runaway reactions during the process, the fluctuating quality of the fertiliser, and rapid equipment wear, have now been eliminated thanks to the two-stage structure implemented in the context of the project. Fluctuations in the composition of the sewage sludge ash can now also be quite easily balanced out by adjusting the formulation. This is claimed to assure consistent high quality. The project partners are now scaling the process up for industrial application. Tests are also to be conducted to determine whether the process can be used to convert liquid manure, for example, as well as other substances, to fertilisers. “The new process makes it possible to close highly effectively a gap in the phosphorus cycle which has, up to now, seriously hindered the sustainable use of this substance,” Hempel summarises.

Project background

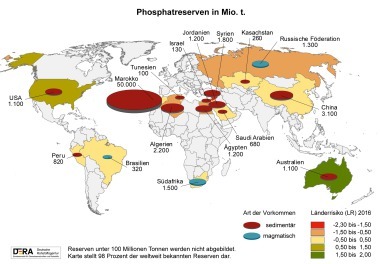

Phosphorus is an important part of the essential elements of life and cannot be replaced by any other substances. It promotes the growth of plants, for example, for which reason large quantities are used as fertiliser in agriculture. Phosphates have, up to now, been extracted in quarries. This has a serious environmental impact, however, is in many cases conducted in countries with difficult political conditions, and also requires large amounts of energy. In addition, the product is frequently contaminated with pollutants. Via the human food chain, a large proportion of phosphorus is ultimately contained in sewage treatment sludge. Because this, in many cases, contains excessively high levels of pollutants, it can no longer be used in agriculture without further processing. There are also alternative recovery methods, but these have, up to now, required large quantities of chemicals and energy.

As long as phosphorus continues not to be recycled, there is a danger of exceeding one of the breaking points defined by international experts for the global ecological system and of missing the opportunity of attaining the United Nations‘ global sustainable development targets adopted in 2015. These are aimed at assuring sustainable development at economic, social and ecological level.