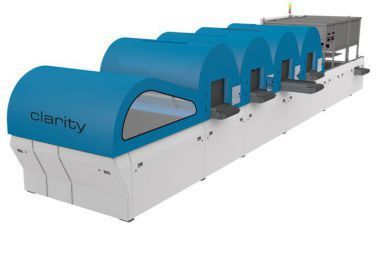

Opening of the biggest plastics sorting plant in Austria

Shortly before Christmas 2017, Saubermacher Dienstleistungs AG placed an order with REDWAVE for the planning and construction of the expansion and renewal of the plastic packaging sorting plant in Graz Puntigam. Around 2 million € were invested in the plant expansion; over the last few years, a total of over 10 million € has been invested in Graz by Saubermacher.

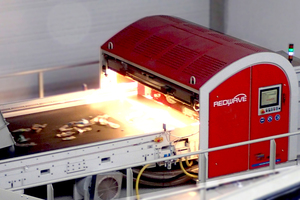

Saubermacher sorts the material on behalf of Altstoff Recycling Austria (ARA). Most of the packaging waste comes from households and businesses. As ever, substances such as glass, paper or residual waste end up in the yellow bin or bag. In Styria, the missorted material accounts for around 23 %. In this plant, the REDWAVE sorting machines, which rely on sensor-based sorting using near-infrared and colour detection technology, separate the plastic packaging by grade. This is essential for its use in the manufacture of new products. “Banning plastic does not help. We must continue to improve recycling and accelerate the use of recycled materials in production processes,“ says Hans Roth, Chairman of the Supervisory Board at Saubermacher.

Plant details

Changes in the contents of the yellow bag made the investment in the sorting system necessary. A new bag ripper to open the “yellow bags” works in conjunction with a new film separator to ensure significantly improved separation of the film fraction from the 3D fraction. In addition, one of the existing REDWAVE sensor-based sorting machines has been technologically upgraded. This sorter has been installed at the end of the sorting line to separate the tetra from the aluminium fraction. An additional REDWAVE near infrared sorting machine of the latest generation can now be found in the vacated space, separating PET from other plastics. The sorting results are further improved thanks to a so-called “bottle flattener” that is situated near to the 2D / 3D separators. This is an in-house development from REDWAVE - a division of BT-Wolfgang Binder GmbH in Gleisdorf. Currently there are no comparable devices on the market that would be able to achieve the capacity required by the customer. The flattened and partially emptied PET bottles processed by the bottle flattener ensure even better sorting results and the associated higher sorting quality.

Aluminium cans and beverage cartons are also now being separated, in addition to 14 different plastic fractions. The automatic plastic sorting plant in Styria/Austria processes around 32 000 t of packaging waste per year, mainly from Graz and its surroundings. In addition, about 40 % of the material is used as a substitute fuel in the cement industry.

“This investment means we can increase the proportion of material recycling to 40 % and thus come one step closer to our vision of Zero Waste”, explained Gerhard Ziehenberger, COO of Saubermacher AG. Silvia Schweiger-Fuchs, managing director at REDWAVE: “Zero Waste is a very important endeavor to keep our environment worth living in for our children in the future. Our environment is a treasure, which we have well preserved internationally in recent decades. We will continue to strive to extend our leading technological position in recycling technology.“

//www.redwave.com" target="_blank" >www.redwave.com:www.redwave.com