Third Berlin Sewage Sludge Conference

Like almost all scientific conferences, the Berlin Sewage Sludge Conference 2020 had to be held as a video conference. TK Verlag GmbH Neuruppin as the organizer of this scientific conference had already practiced such an approach several times in the recent past, so that the sewage sludge conference on November 16 and 17, 2020 proceeded adeptly and without complications.

After a short welcome by the managing director of TK Verlag GmbH, M. Sc. Elisabeth Tomé-Kozmiensky, Dr.-Ing. Olaf Holm, from the same publishing house and responsible for program coordination, gave a short introduction to the topic. First, he thanked the „loyal participants“, the program committee (Prof. Dr.-Ing. Peter Quicker, RWTH Aachen and RA Stefan Kopp-Assenmacher, Kopp-Assenmacher & Nusser Partnerschaft von Rechtsanwälten mbH, Berlin) as well as the advisory board (Dr.-Ing. Christian Adam, BAM, Berlin; Prof. Dr.-Ing. Matthias Barjenbruch, TU Berlin; RA Dr. Tobias Faber, Hogan Lovells Internat. LLP, Frankfurt a. Main and Min. Rat a. D. Michael Spitznagel, DPP e. V., Frankfurt a. Main). Particularly warm thanks were expressed to the last-mentioned member of the Advisory Board, who is now retiring from this body. Likewise, Dr. Holm singled out all the speakers who, without feedback, would have to speak their papers into a lens – not a very easy undertaking.

While the two previous sewage sludge conferences were mainly concerned with the legal requirements that have led to a rethinking of sewage sludge utilization and with theoretical issues, as expected, 2020 saw a greater focus on practical issues, as the time to implement the requirements of the AbfKläV is not too long.

The morning session of the first day was held as a plenary session with topics on the political situation and on the LAGA implementation aid, followed by a corresponding panel discussion.

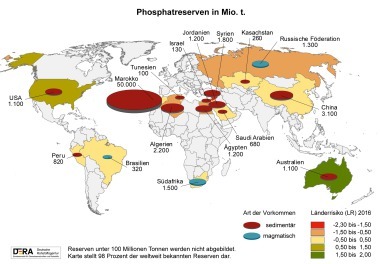

Ministerial Councillor Hans-Peter Ewens, BMU Bonn, spoke on „New developments in the Sewage Sludge Ordinance“ and reminded the audience that the AbfKläV, which is now three years old, represents a milestone on the way to phosphorus recovery from sewage sludge. We are still a long way from the targets; in 2018, 1.57 million t of sewage sludge were produced in Germany, of which around 75 % were thermally recycled. In the future, however, thermal recycling should also serve P recovery. The reason for this is not so much a shortage of P resources, but rather the concentration of deposits in a few countries (five countries extract around 75 % of the P raw materials), the increasing demand worldwide and the massive deterioration in mining conditions. After the comprehensive overview of the innovations of the regulation and the first enforcement aid issued for this purpose, the speaker dealt with the experiences that have been gathered in the meantime. New issues have arisen from enforcement for which the enforcement guidance does not provide explanations. Min. Council. Ewens emphasized the importance of future joint action by the federal and state governments in the enforcement of the AbfKläV. He concluded with some remarks on European developments, including the announcement of the review of the EC Sewage Sludge Directive (evaluation of the same in 2021). However, it is still open whether a Europe-wide obligation for P-recovery will be enforced.

Practice-relevant topics were the focus of the following two presentations. „Current and future framework conditions for sewage sludge disposal from the point of view of a project developer“ was discussed by Dipl.-Ing. Jörn Franck, JOMA Umwelt-Beratungsgesellschaft mbH, Hamburg. He began by highlighting the paradigm shift facing sewage sludge treatment and disposal with the new AbfKläV and outlined the current situation, which is characterized, among other things, by further tightening environmental legislation, changing disposal structures in the field of soil-related and thermal recycling of clear sludge, rising disposal costs and, in some cases, outdated mono-incineration plants in need of rehabilitation (some have been in operation for > 40 years). Furthermore, the speaker discussed the new planned projects: with 44 plants for 1.2 million tds/a and the 0.6 million tds/a of the existing plants, sufficient capacities should be provided. The number of plants as well as their throughputs are very different in the individual federal states (Bavaria: number 10; Saxony: 0). Further remarks referred to the technologies (mainly stationary fluidized bed), project developments (investors, operator models) and organization, site selection and characterization of the sewage sludge as well as costs and financing. In his conclusion, Franck highlighted that P recycling processes are not yet ready for the market, with some at the beginning of large-scale testing, public acceptance for new plant projects is very low and urgently needs to be improved through transparent public relations work during the approval phase.

„The Hessian Way to Phosphorus Recycling“ was presented by Dipl.-Ing. Simone Apitz, Hessisches UM, Wiesbaden. The state of Hesse has recently developed its own resource protection policy, in which P-recovery is also integrated. Regional solutions are being sought, and a number of activities are underway. For example, a feasibility study has been commissioned, on the basis of which corresponding demonstration projects are to be realized. After that, pilot projects for the practical implementation of the regional phosphorus cycle have to be developed.

Panel discussion

Under the chairmanship of RA Kopp-Assenmacher, Dipl.-Ing. Simone Apitz, Min. Councillor Stefan Ewens, Dr. Christian Kabbe, EMG EasyMining Germany GmbH, Berlin and Andreas Versmann, Consultant Environmental Law/Environmental Policy, Berlin discussed the topic of „Sewage Sludge Utilization and Circular Economy“. After a short statement of the panelists mainly regarding the experience gained since the new AbfKläV came into force, the discussion focused mainly on

The paradigm shift of the EU regarding environmental policy with the aim of modernizing the European economy and integrating environmental protection into a European industrial policy

Germany‘s position within the EU regarding circular economy and sewage sludge recycling (strengthening resource efficiency in products, consumer choice for sustainable and recycled products, strengthening waste prevention and promotion of repair activities e.g. through action plans as in other EU countries)

Does EU law with the hierarchy of material recycling before thermal stand in the way of the preferred option in Germany

End-of-waste discussion: classification of sewage sludge / sewage sludge ash as waste or product – in contrast to the EU, much stricter criteria apply in Germany in this respect

Legal issues – new balance between recycling and environmental protection - foreseeable tightening of limits (heavy metals, pharmaceuticals, etc.)

Additions of other P-containing substances (animal meal, wood) to sewage sludge incineration – sensible, not yet legally enforced, further discussion sought

Establishment of intermediate sewage sludge storage facilities by the states until appropriate plants are commissioned – currently there is no disposal emergency, but the situation is tense, so nationwide collection makes sense. In addition, the cost explosion of 2017/18 continues.

The panel discussion showed the challenges faced by policy makers as well as project designers, investors and plant operators. It is important to get the first plants up and running; various processes are on offer, low-cost processes need to be found, market-relevant volumes need to be made available, and market opportunities need to be identified. It must be borne in mind that the recyclates do not yet necessarily constitute fertilizers, but still have to be refined. The transposition of the European requirements into national law is showing positive signs, but an amendment of the European Sewage Sludge Directive is necessary, whereby the directive must first be evaluated and the amendment carried out around 2022/23. Germany should be involved in this process and play a pioneering role.

The continuation of the event in the afternoon and the next day was dedicated to 30 technical papers with the following main topics:

Phosphorus recycling (7 papers)

New/alternative process projects (3 contributions)

Incineration – incl. new construction projects (7 contributions)

Dewatering/Drying (4 contributions)

Flue gas cleaning/vapour treatment (1 entry)

Legal aspects (4 contributions)

Financing (3 contributions)

Operator models (1 entry)

In line with the objective of „recovery“, only a few remarks were made on the subject of phosphorus recycling, all of which show that great efforts are being made to transfer the theoretically well thought-out process approaches, which have been tested on a laboratory scale, into technology as soon as possible and to build appropriate plants.

Johannes Pinnekamp, FiW e.V./ RWTH Aachen, presented the RePhoR networking and transfer project TransPhoR and explained its tasks and objectives. The project unites 7 regional joint projects (e.g. DREISATS – Technology Demonstration for the Combination of Dust Firing and Acid Digestion Granulation with Integrated Heavy Metal Separation for Regional Phosphorus Recycling in the Central German Tri-State Area of Saxony-Anhalt, Thuringia and Saxony or R-Rhenania – Modified Rhenania Phosphate from Sewage Sludge Ash for Bavaria), which are intended to contribute to the sustainable implementation of the new AbfKläV with various approaches to regional P recycling (recovery of different P recyclates from the various material flows – wastewater, sewage sludge, sewage sludge ash). In addition, the project is also concerned with the further development of standardized test methods and product criteria for P recyclates, as well as the development of general criteria for the comparative assessment of economic efficiency and life cycle assessment. (further information at www.bmbf-rephor.de)

Veolia‘s approaches to „Holistic P recycling from the wastewater treatment plant to mono-ash“ were explained by Dr.-Ing. Matthias Staub, Veolia Klärschlamm Deutschland GmbH, Makranstädt. With two different routes that Veolia is taking - P recovery a) at the sewage treatment plant (Phosforce approach) and b) from sewage sludge ash (pontes pabuli approach) – the company has a unique selling point. Both processes were presented in detail and weighed up against each other. Practical experience with the Phosforce approach was gained on a laboratory scale and at pilot plants in Schönebeck, Lille and Treguier (France). Construction of a demonstration plant in Schönebeck is planned for 2021 and commissioning in 2022. From the results, it can be concluded that pathway a is possible and recommended for contents < 30 g P/kgds, especially for bio-P elimination. Path b is most reasonable at P contents > 40 g/kgds.

The way and the experiences of REMONDIS were shown by Roland Ruschewey, REMONDIS Aqua GmbH & Co. KG, Lünen in his contribution „First-time implementation of P recycling from sewage sludge ashes using the Tetra-Phos® process“. The process (sewage sludge mono-combustion) is to be operated on an industrial scale in Hamburg. In addition to P (RePacid with 80 % H3PO4), Ca (gypsum), Al and Fe (salts) are also recovered. The process won the Green Tec Award in 2016 and was included in the Environmental Innovation Program in 2017, and a contract was signed with the Hamburg sewage treatment plant in 2018. Commissioning (trial operation) is planned for 01/2021 with a throughput of 20 000 t/a.

Another P-recycling process was demonstrated by Jan Kirchhof, Glatt Ingenieur GmbH, Weimar and Thorsten Brumme, SERAPLANT GmbH, Haldensleben: „Phos4green – Implementation of a plant for the production of 60 000 t/a fertilizer from sewage sludge ashes at the Haldensleben site“. After acid digestion of the ashes with the addition of additives, spray granulation takes place, and it is possible to manufacture a wide variety of products according to customer requirements. In addition, liquid and/or solid nutrient components can be added. In laboratory and pilot tests, various products with ideal particle size distribution and good hardness for agriculture have been produced, which show very good planting results and comply with the limits of the DüV (heavy metals). For the plant in Haldensleben, the start of production is planned for 01/2021, initially for the production of the fertilizer P38 for organic farming.

A joint project between Gelsenwasser AG and Easy Mining, the developer of the Ash2®Phos process, is planned at the Wolfen Chemical Park, as reported by Dipl.-Ing. Tim Bunthoff of the former company. For the demonstration plant operating according to this process with a throughput of 30 000 t sewage sludge ash/a, which is currently in the planning and approval phase, the start of construction is scheduled for 03/2022; a plant for 60 000 t ash/a is to follow later. Nationwide, treatment capacities of 300 000 t ash/a are to be created by 2030.

The important topic „Market potential and logistics in P-recycling“ was dealt with by M. Sc. Fabian Kraus, Kompetenzzentrum Wasser Berlin gGmbH. He showed that, depending on the product (calcium phosphate, phosphoric acid, ammonium phosphate, struvite), recycled phosphates can be used either as raw material for the fertilizer industry or via direct marketing. Both routes have been extensively verified, also taking into account the extreme price variations between products (20 .... 120 €/t for struvite and other Mg-based products). Regarding the logistic effort, the sites of mono-incineration plants are quite suitable for thermal processes, while chemical processes should be centrally located in chemical parks.

Also worth mentioning is the contribution „Approaches to alternative thermal sewage sludge treatment“ by Prof. Dr.-Ing. Peter Quicker, RWTH Aachen, who gave a critical appraisal of the same (hydrothermal carbonization, pyrolysis, gasification, metallurgical processes). He came to the conclusion that currently none of the alternative thermal processes discussed offers the technical prerequisites required for stable long-term operation with regard to sewage sludge treatment (difficult reaction control, inferior products, technical difficulties), so that he urgently advises against investment in such technologies and describes incineration as the state of the art for sewage sludge treatment.

Concluding remarks

Even though the pandemic „only“ allowed a video event, the third Berlin sewage sludge conference can be described as very successful. There were only a few changes to the original program, and the event ran in a very disciplined and well-organized manner. The number of participants also hardly suffered from the changed form of implementation. The progress made on the basis of numerous experiences, both with regard to the interpretation of the new Wastewater Treatment Ordinance (AbfKläV) and to the state of the art in recycling processes, with regard to the construction planning and design of incineration plants, the financing of projects, and also the further development of processes and analysis methods, was comprehensively presented and discussed in more than 30 papers. Especially the processes that are about to be launched on the market and the plants that will be commissioned in the foreseeable future gave rise to a profound discussion. This applies not only to the thermal recycling processes themselves, but also to pretreatment processes such as dewatering and drying. The audience was provided with a wide range of knowledge and experience, which can also be deepened after the conference by studying the digitally provided technical book „Verwertung von Klärschlamm – 3“, Thomé-Kozmiensky Verlag GmbH, Neuruppin 2020, ISBN 978-3-944310-52-7. Once again, we would like to thank the organizer for this.

The next sewage sludge conference is planned for November 15 and 16, 2021 in Berlin.