ANDRITZ to supply sludge incineration plant to Wuppertal/Germany

03.12.2025The German company Klärschlammverwertung Buchenhofen GmbH (KVB) has awarded international technology group ANDRITZ an order to build a new mono-incineration plant for sewage sludge in Wuppertal-Buchenhofen. The new plant will enable future-proof thermal sludge treatment and later serve as a preliminary stage for the recovery of valuable phosphorus, while also contributing to renewable energy production. It will replace the existing sewage sludge incineration plant of the Wupperverband water management association.

Visualization of the new sludge incineration plant in Wuppertal-Buchenhofen

Visualization of the new sludge incineration plant in Wuppertal-Buchenhofen

© KVB GmbH

The order value, close to 100 million €, is included in ANDRITZ’s order intake for the third quarter of 2025. This is the fourth order received by ANDRITZ for the supply of a sewage sludge mono-incineration plant to Germany within just over a year.

Dirk Salomon, Managing Director of KVB GmbH, says: “We chose the plant concept proposed by ANDRITZ after a complex, competitive negotiation process because they presented a highly efficient solution in terms of investment and operating costs as well as energy utilization and flue gas cleaning. We look forward with great expectations to the next steps of joint project implementation, working closely with the team of the existing plant and drawing on their many years of operating experience.”

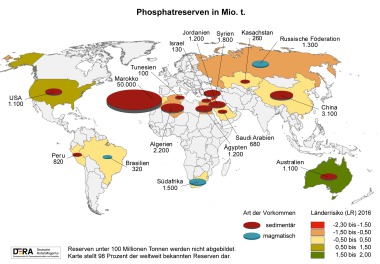

The state-of-the-art plant will burn municipal sewage sludges from ten public partners in North Rhine-Westphalia, enabling a resource-efficient and environmentally friendly treatment in compliance with the German Sewage Sludge Ordinance (AbfKlärV), which mandates the recovery of phosphorus in the future. This recovery requires a separate process using specialized technology. The European Commission classifies phosphorus as a critical raw material, essential for agriculture and industry. Mono-incineration of sewage sludge produces ash from which phosphorus can be recovered. The steam generated during incineration will be used to produce electricity (approx. 2 MW) and heat (approx. 8.5 MW).

The plant will have a capacity of 47 500 tons of dry matter per year. It will comprise systems for sewage sludge reception, conveying, drying including vapor condensation, incineration using an adiabatic EcoFluid bubbling fluidized bed (BFB), and a downstream boiler for steam generation. The scope of supply also includes an advanced multi-stage flue gas cleaning system, steam turbine, generator, water-steam cycle, complete electrification and automation as well as auxiliary systems.

“We are very pleased that such an experienced customer, who has been operating a sewage sludge incineration plant since 1977, sees the added value in our advanced technologies,” says Benjamin Klammer, Project Manager, Sales at ANDRITZ. “This project is a perfect example of our commitment to advancing the circular economy through sustainable solutions.”

ANDRITZ’s scope of supply comprises the engineering, supply, erection, and commissioning of the entire plant. Operations are scheduled to begin in April 2029.