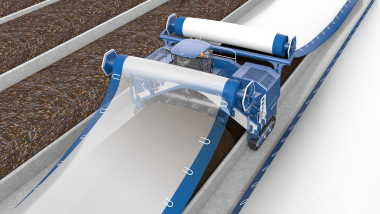

Pre-treatment of digestates with the Digestate

Dryer BRT HARTNER DCD

A water content that is too high can slow down the composting process and reduce the quality of the final product. The Digestate Dryer of the Eggersmann brand BRT HARTNER homogenises, loosens and dries digestates and fermentation residue. At the same time, ammonia is driven out of the material by pressure ventilation.

The material needs to be ventilatable for the conditioning or drying of digestates. To ensure this, structural material is added to the digestate before treatment according to the consistency. Depending on the project-specific conditions, this can be fresh material or recycled material from one of the subsequent treatment steps or from the output of the machine. The fermentation residues are merged and mixed with the added substrates. Simultaneously, water vapor and ammonia are driven out by the exhaust air system. After treatment in the Digestate Dryer, the material is optimally suited for the subsequent processes.

The Digestate Dryer BRT HARTNER DCD is designed as a fully automated continuous dryer. The material is moved through the machine with a scrape chain conveyor. The supply of thermal energy is achieved via the bottom plate, on the one hand by active warming of the material with the incorporated floor heating, on the other hand by coupling of pre-heated supply air via channels in the bottom plate. With a useful length of approx. 24 500 mm, the power output of the floor heating is max. 400 kW (therm) and the power output of the air heating is max. 3 x 270 kW (therm) at the maximum supply air volume flow (3 x 24 000 m³/h). The pressure ventilation of the material with preheated air ensures an optimised output of water and ammonia via the exhaust air. The exhaust air gets captured in the closed unit above the material and is then fed to suitable exhaust air treatment.

The conveying line of the machine is equipped with special mixing and turning rollers. The material is thoroughly mixed, homogenised and loosened up in these areas during treatment. The decompaction unit at the discharge side ensures an even material output, also with a material height of more than one meter.

With a filling volume of 60 m³, the throughput capacity and the treatment time in the Digestate Dryer can vary depending on the material composition and the project goal from 10 to 120 m³/h, respectively from 0.5 to 6 hours.