Interview with Ulf Harig

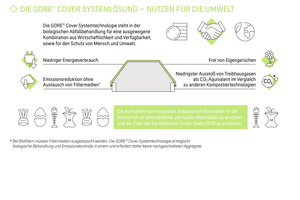

The revised Waste Framework Directive (Directive 2018/851/EU, §10) stipulates that by the end of 2023 organic waste must either be collected separately or recycled at source. Municipalities must therefore look into the various composting systems in order to treat the organic waste that will be generated in the future in a sensible manner. Currently, there are about 3800 composting plants in Europe, and according to forecasts, there will be twice as many in 2030. A cost and eco-efficient way to produce high quality compost is to use special semi-permeable membranes – a modern technology for operational enclosure of composting plants.

One of the market leaders in this field is GORE® Cover System technology from W.L. GORE & Associates. Ulf Harig started as Business Leader for Solid Waste Treatment at W.L. GORE & Associates about 20 years ago. In this interview, the expert talks about the challenges and opportunities facing the industry in light of the new regulation.

What challenges does the composting

industry currently face?

Ulf Harig: The challenges are mainly in collection. Europe produces about 130 million tons of biowaste annually, of which less than half is collected separately today. Clearly a missed opportunity, because only separated biowaste can be composted. And if we zoom out even further and look at the whole world, we‘re talking about over one billion tons of biowaste annually. An unbelievably large amount. You can either see this as a threat to the environment, or – and this would be the positive way of looking at it – you can welcome it as an opportunity: there is great potential worldwide to produce high-quality compost in a sustainable way, which we can use to return valuable minerals to the soil.

What are the general challenges in the

actual composting process?

Ulf Harig: There are three areas that are challenging: Odor, water and the amount of land required. The biggest issue, especially with open composting, is definitely the odor, especially for residents. This is because composting releases gas – and therefore odor – due to chemical processes. The emissions are ammonia as well as volatile organic compounds (VOCs), the generic term for all chemicals that vaporize and contain carbon. From an environmental perspective, we should avoid releasing these gases into the atmosphere.

The second challenge is water. A compost pile needs sufficient moisture for the decomposition process to take place. So it must not dry out, but at the same time it must not get too wet, so it must be protected from too much water, while maintaining the existing process moisture.

The last point that poses a challenge is the area, i.e., the size of the composting facility. For example, a convenient size of a windrow is 8 m wide, 3 m high and up to 50 m long. This requires a large area and thus, of course, a high investment according to the space required.

Which composting technology can you

recommend?

Ulf Harig: There are basically two options for composting: open or closed systems. The closed windrows with a building and biofilter require a complicated air treatment to allow an aerobic composting process. Water usually must be added to this process, and large amounts of air must be filtered to reduce VOCs and ammonia, making this type of composting very energy intensive. The open systems have the problem of keeping the desired parameters constant under different weather conditions – changing temperature, sunshine and precipitation.

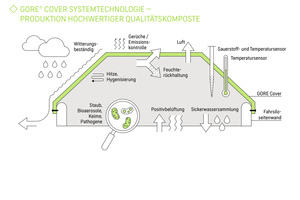

With GORE® Cover System technology, you get the best of both worlds – the cover, or operational enclosure, composting system with a special semi-permeable membrane that provides the benefits and efficiency of a closed system at a low cost. It is equipped with positive aeration and oxygen and temperature monitoring device. This creates ideal composting conditions and eliminates the need for costly air treatment systems such as a biofilter.

How does GORE® Cover meet the challenges of composting?

Ulf Harig: The GORE® Cover system technology uses a semi-permeable membrane, which means that rainwater does not get in, but the injected air can escape from the rotted material. As the biowaste decomposes, heat and water vapor are generated. Basically, the outside temperature is lower than the temperature in the compost bin, so condensation occurs on the inside of the GORE® Cover. The pores of the membrane allow only a small amount of water vapor to escape, leaving optimum moisture in the rotting process. Oxygen is injected through the aeration, which can escape again through the membrane, which is very important because composting is an aerobic process, i.e. oxygen is needed. The technology also meets the odor challenge: with the GORE® Cover Membrane, we can always reduce more than 90 % of odors.

We also need much less space compared to open windrow. Because the composting process is optimized by the membrane and active aeration, we can plan a higher compost windrow, saving many square meters of floor. Accordingly, for example, less leachate needs to be collected and processed. This reduces not only the investment for the plant, but also the operating costs: Composting with GORE® Cover System technology is extremely cost-friendly.

Another advantage of the system is that treatment time can be reduced: We can produce a good compost in 2 months with GORE® Cover. The eco-efficiency is also impressive: Namely, the membrane is very durable and is not attacked by microbes or bacteria. With an average life of 8 years, it is one of the most sustainable solutions on the market.

There are more than 300 plants worldwide using GORE® Cover System technology. We have received only positive feedback on our system, which is reflected in many long-term customer relationships.

What organic waste can be composted with GORE® Cover System Technology?

Ulf Harig: The cover is suitable for various types of organic waste, both green waste, kitchen waste, the organic waste garbage can, and digestate can be converted into high-quality compost using the same membrane. At the beginning of any composting process, various parameters must be adjusted – for example, the water content must be around 65 %, also the carbon-nitrogen ratio should be adjusted. Since these desired parameters are always the same for different types of organic waste, one version of the cover is sufficient. GORE® Cover is suitable not only for different organic waste types, but also for different plant sizes – from small to large. The system is very flexible.

What developments in composting are currently being researched?

Ulf Harig: Composting has been around for thousands of years, but there are two exciting developments being researched: Biogas and insect breeding. Food waste, kitchen waste, is great for biogas. From biogas we can produce biomethane, which can be used instead of natural gas. The energy crisis has once again highlighted the importance of alternatives to gas. Incidentally, the digestate from biogas production goes to the composting plant for maximum utilization.

The second development concerns insect breeding. There is biowaste that is very suitable as a substrate for insect breeding. We have the most experience with mealworm, from which we can obtain good proteins that can replace soy as feed, for example. And the nice thing is that here, too, the leftovers are returned to composting. So the cycle, the circular economy, is put to good use.

Looking to the future: What challenges does the Waste Framework Directive requirement bring?

Ulf Harig: First of all, we experts are very happy about the directive. Now it is finally specified what has to be done: biowaste must be collected separately and there is a clear deadline for this. All member states have to introduce this – and that‘s a good thing. However, for some countries it will be a big challenge.

We know what investments we have to make, how we have to operate the plants, but there is one point we must not forget: All households need to participate, which means we need very strong communication. We should think about how to motivate households to separate their waste. And to separate it properly. After all, if just 5 % of organic waste does not fit, i.e. contains foreign matter, it cannot be used as compost. No farmer will be able to use compost with impurities of plastic or glass. This is why separate collection at the source – households – is so important, because everyone has a personal responsibility for the quality of the final compost product. In addition, the cycle must be closed. It is of little use if organic waste is collected and processed into compost, but this compost is not reused. Therefore, it is important that farmers also actively participate and use compost for their farming.

Optimistically, in 10 years we will probably have over 130 million tons of organic waste in Europe, of which we will hopefully then be using over 90 % in the cycle.

Ulf Harig started as Business Leader for Solid Waste Treatment at W.L. GORE & Associates about 20 years ago. During this time, he has been involved in the market development of GORE® Cover System technology. The production and logistics engineer is a proven expert in organic waste treatment in reference to global needs and high compost qualities.