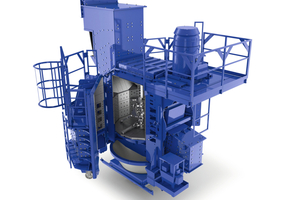

BHS-Sonthofen launches further optimised rotor shredder on the market

BHS-Sonthofen has now further optimised its rotor shredder based on many years of operating experience with customers. The machine is characterised by greater wear resistance and ease of maintenance. In recent projects, the rotor shredder has proven itself particularly in the applications of waste incinerator bottom ash (IBA) and electronic scrap, light metal scrap and white lead processing.

As one of the technology leaders in the recycling of metal-containing composite materials and industrial waste, BHS is committed to continuous development. The latest generation of the rotor shredder incorporates the practical experience of customers from various applications. The machine has now been specifically optimised on this basis. “We value the dialogue with our long-standing customers and try to incorporate their improvement requests into the machine design in the best possible way,” reports Ulrich Kanzleiter, Area Sales Manager DACH.

The BHS rotor shredder optimally shreds, separates and isolates valuable, residual and composite materials containing metal. The shredding tools exert a high intense stress on the feed materials through impact, shock and shearing forces. The result is selective disintegration: material composites are separated and the piece sizes are specifically reduced and exposed for subsequent sorting.

The slatted grate has been made more solid and the openings have been redesigned. This makes the machine more wear-resistant and easier to maintain. A second optimisation concerns the automatic slider for impurities. BHS has adapted it so that impurities can be discharged from the machine even more smoothly through a larger gap. “We have further developed the stability of the rotor shredder especially for particularly abrasive materials. The control sequence for recognising heavy parts has also been significantly improved and has already proven itself in use with waste incineration slag and electronic scrap to the full satisfaction of our customers,” says the responsible design engineer Stefan Schratt. “Overall, the rotor shredder achieves an ideal output result for a variety of different feed materials, which customers at our test centre confirm time and time again.”

In addition to electronic scrap, the feed materials include motor armatures and electric motors (so-called “meatballs”), aluminium scrap, automotive shredder residue fractions (ASR), waste incineration scrap and waste incineration slag, as well as light metal scrap such as that produced in MBT (mechanical-biological waste treatment plant) and DSD (waste packaging) sorting plants.

The new generation of rotor shredders impresses with its robustness, uncomplicated maintenance and versatile application options.