RS rotor shredder and RPMV rotor impact mill in modernized processing lines at Immark AG

As is so often the case, something big started small. In 1936, Gustav Thommen founded a scrap metal trading company in Basel (see photo). This marked the birth of today‘s Thommen Group with its 25 locations in five countries.

Back to the beginning: under Gustav Thommen, the company grew steadily and the old location in Basel became too small. In 1950, he found a suitable site in Kaiseraugst, which offered the advantage of a direct rail connection.

In 1970, René Thommen took over the family business. In 1971, the first shredder plant was put into operation at the Kaiseraugst site. This meant that metals were not only collected and resold, but could now also be processed and sorted.

Like this father, René Thommen and his son Stephan successfully continued to run the recycling company and expanded it with additional locations, new technologies, and services. 2011 Dr. Tobias Thommen took over the company management and expanded successfully into new markets and business areas by acquiring companies and shareholdings in Switzerland and abroad. Today, the Thommen Group is one of Switzerland‘s largest recycling companies for the trade, recycling, and processing of metal, iron, and electronic scrap, with a total of 33 locations in Switzerland, Belgium, Germany, Italy and China. Around 900 employees work for the Thommen Group, and Pouyan Dardashti has been the new CEO since 2023.

The Immark AG has been part of the Thommen Group since 2009. Founded in 1986, Immark is a pioneer and Swiss market leader in the disposal and recycling of waste electrical and electronic equipment. Immark AG, with locations in Regensdorf, Aarwangen, and Liestal, is a licensed partner of the SENS and SWICO take-back systems. Immark achieves a recycling rate of up to 95 %. The recovery and processing of metals is particularly important for conserving resources and reducing CO2 emissions. For example, producing aluminum from aluminum scrap consumes 95 % less energy than producing aluminum from bauxite. High product quality and purity as well as effective processes are necessary to make recycling economically viable. That is why the Thommen Group is constantly modernizing and investing in new technical solutions. This was also the reason for new reconstruction of the processing line at the Regensdorf site.

The main step in the new line is the shredding of old electronic and electrical equipment. The RS 2018 rotor shredder from BHS Sonthofen went into operation at the beginning of 2023, with the official handover of the machine taking place on December 15, 2023. Immark AG had previously chosen BHS Sonthofen to modernize the comminution unit for fine processing. An RPMV was delivered in 2016. This is a high-performance shredder with a vertical shaft. It is mainly used for breaking up metal compounds, shredding brittle components, and pelletizing metals in the size range of 5 to 30 mm. The unique beater rotor in combination with the toothed ring armor causes intensive stress on the feed material. Material composites are selectively shredded and separated, material tangles are broken up, and brittle, hard materials are shredded very finely. At the same time, metals are pelletized and cleaned.

This new rotor impact mill replaces an RPMV 1513 rotor impact mill already supplied by BHS to the AG in 2001.

Interview: “Today, we go far beyond simply collecting waste”

The editorial team of recovery magazine had the opportunity to visit the modern facilities at the beginning of 2025 and spoke with Matthias Ebneter, COO of Immark AG, and Nicolas Huber, production manager Immark AG at the Regensdorf site.

recovery: Mr. Ebneter, perhaps we could start with a brief overview: What does IMMARK AG and the Thommen Group stand for?

Matthias Ebneter: The name Thommen is primarily known in Switzerland as a specialist in ferrous and non-ferrous metals, while Metallum is known on the international market and Immark stands for the electronic scrap division.

recovery: How big is the company today? And is it still family-owned?

Ebneter: Yes, the Thommen Group is still a family business, now run by the third generation. We employ a total of around 900 people in Switzerland and other European countries.

recovery: You mentioned processing – how far does this process go at your company?

Ebneter: Immark AG focuses on the mechanical shredding and processing of waste electrical and electronic equipment. We achieve a level of processing quality that allows the material to be used directly in smelting plants or in plastics processing.

recovery: What are the material flows like in Switzerland — are there take-back systems or collection points?

Ebneter: In Switzerland, this is done through established take-back systems run by SENS and SWICO. With over 600 collection points, we have a dense network for the free return of electronic waste. This system enables us to achieve one of the highest return rates in Europe.

recovery: Is the utilization of your facilities constant, or are there seasonal fluctuations?

Ebneter: The market is basically stable. We have a constant amount of material, but it fluctuates seasonally. We see peaks in returns, especially between Black Friday and Christmas. During this time, we operate in three shifts to handle the volumes. Over the course of the year, we usually work in two shifts, five days a week.

recovery: Where are your most important facilities located?

Nicolas Huber: Plants for pre-sorting waste electrical equipment are located in Liestal, near Basel, and in Regensdorf. There, we prepare the material so that it can then be further processed at our new treatment plant in Regensdorf. Another plant focuses on refrigerators. Virtually 100% of the material comes from Switzerland, of which we process around 70% – the material flow is also largely constant here.

recovery: You collaborated with BHS Sonthofen on your new plant in Regensdorf. How did this partnership come about?

Huber: We have been working with BHS since 2001. Back then, we installed the first BHS mill with the comminution line for fine processing—it is still in operation today and was modernized in 2016. When the capacity of our old processing line reached its limits in 2022, we developed a new comminution line and opted for the BHS shredder. The shredder was tested in Sonthofen with our material at the technical center there and then installed in Regensdorf in 2023.

recovery: What was the goal of this investment?

Huber: We wanted to increase our capacity and improve efficiency as well as the recycling and recovery rate. The new plant has been completely redesigned— only the fine processing section is still from a previous overhaul in 2016. The focus is on shredding electrical appliances, except for refrigerators containing refrigerants and batteries.

recovery: How does the material processing work in concrete terms?

Huber: The delivered material is first manually pre-sorted and sorted. Batteries and other impurities are removed before the material is sent on for shredding. The challenge is that the appliances are delivered unsorted and in a “wild mix” – usually in pallet frames. Therefore, purely automatic sorting is not yet technically possible. This requires a great deal of expertise from our specialist staff.

recovery: When did the new plant go into operation?

Huber: In 2023. We designed it to be modular so as not to interrupt the ongoing operation of the old plant. That was very challenging – we had to replace the old line step by step. Overall, the plant consists of several modules that can be operated or maintained individually.

recovery: Why this modular design?

Huber: The modular design greatly increases our flexibility. We can shut down individual modules for maintenance or in the event of malfunctions without stopping the entire operation. In addition, the system can be adapted to new types of material or technological developments. We can also feed material into individual components of the processing plant without having to run it through the entire line.

recovery: How did the test phase with BHS go?

Huber: We brought pre-sorted material to BHS in Sonthofen. There, various parameters of the rotor shredder were tested to determine the optimal combination of plant components. This enabled us to ensure that the crushed material could then be processed ideally.

recovery: What results have you achieved with the new plant since it went into operation?

Huber: Overall, very good. Of course, we had to make some fine adjustments at the beginning — for example, to the speed, the configurations of the grates, and the tools. But now the plant is running smoothly, with higher throughput and better sorting results than when it was commissioned.

recovery: What are the advantages of the new plant compared to the old one?

Huber: In addition to higher throughput and efficiency, we are achieving significantly cleaner material fractions, which increases the value of the recycled materials. We can also make operations more energy-efficient and safer. All of this contributes to better profitability and sustainability.

recovery: What are the prospects for the future? Are there any new projects or investments at Immark AG?

Huber: Two major investments – the refrigeration plant and the new electrical recycling plant – have been completed. The task now is to consolidate and optimize the plants. There are also plans for a new pre-sorting plant at the Liestal site near Basel to replace the existing one. This will go into operation at the end of 2025. We are also investing heavily in the digitization of our processes – from the flow of goods to production control.

recovery: And how do you see the political and economic situation of recycling in Switzerland?

Ebneter: Recycling is a high priority in Switzerland, both politically and socially. Nevertheless, we must always examine what is economically feasible so that jobs in Switzerland remain secure. It is important that we clarify the framework conditions at an early stage and position ourselves well as a small but efficient market that is aligned with Europe.

recovery: Thank you very much for the interesting insides!

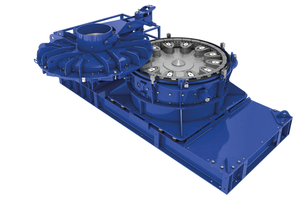

Two series for perfect output: RPMV & RPMX

For years, the rotor impact mill has been setting standards in the recycling industry for the processing and recovery of valuable materials from metal-containing fine fractions. Depending on the process and material requirements, the two series RPMV are available for a wide range of applications and the RPMX for perfect fine processing.

The RPMV has proven itself many times over worldwide in the recycling industry for dissolving metallic compounds, crushing brittle components, and pelletizing metals in the grain size range from 5 to 30 mm. The feed material is fed into the working chamber from above in the center. When it hits the rotor, it is accelerated outwards by centrifugal force, caught by the horseshoe-shaped impact hammers and thrown against the ring armor. The rotation creates a definable grinding gap between the tips of the impact hammers and the ring armor, in which intensive impact and shear comminution takes place. The feed material is processed until it reaches the target size and then falls down through two discharge chutes.

fine processing

Metal composites and metal-containing waste materials can be crushed, separated, isolated, pelletized, or cleaned. An essential prerequisite for the efficient separation and sorting of non-ferrous metals and other materials.

BHS offers complete system solutions, such as steel construction in various designs, bunker and dosing technology, feeding and discharge technology, classification and separation technology, and dust extraction systems.

Brittle materials are finely shredded, material composites are separated, and material tangles are broken up. Rubber and plastic parts remain largely intact but are separated from other materials. Metals such as copper or aluminum are pelletized.

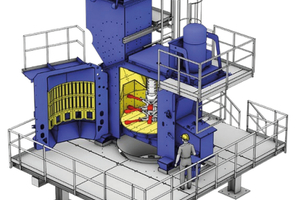

BHS rotor shredder RS 2018

The BHS rotor shredder RS 2018, which is in use at Immark in Regensdorf, consists of a cylindrical working chamber with a vertical shaft. Working tools are arranged in pairs above each other in a flying configuration. Centrifugal force aligns and stabilizes the working tools horizontally. The feed material is fed into the working chamber from above and subjected to very intense impact, collision, and shearing forces when it enters the impact circle of the tools.

After only a short time, the selectively shredded material leaves the machine continuously and without coercion through the slotted grate. Solid individual parts that cannot be shredded can leave the working chamber through a separate sluice.

The flexible suspension of the tools on the shaft also serves as overload protection. Optionally, the rotor shredder can be equipped with a flywheel as an energy storage device.

The cylinder wall is double-walled. The inner wall consists of a solid slotted grate, the openings of which can be customized.

The EU directive on the treatment of electrical and electronic waste requires the reliable separation of certain components containing harmful substances.

The BHS rotor shredder can separate components containing harmful substances, such as batteries, capacitors, and assembled circuit boards, from the composite without completely destroying them. These contaminants can be reliably sorted out of the material stream after shredding.

Simple tools

Flexibility

Continuous operation

Resistance to contaminants

Easy to maintain

Low running costs