Terex Ecotec Shredder triples capacity for Rogaland Gjenvinning

23.10.2025Rogaland Gjenvinning, a leading waste and recycling company based in Sandnes, Norway, has tripled its wood processing capacity while reducing its diesel consumption and CO₂ emissions following the installation of a Terex Ecotec TBG 630E Electric High Speed Shredder.

Founded in 2018 by experienced professionals from the waste and construction sectors, Rogaland Gjenvinning operates a state-of-the-art sorting facility in Soma, the western part of the large municipality of Sandnes/Norway. The company offers tailored waste and recycling solutions to both private individuals and businesses, with a strong focus on customer service, competitive pricing, and environmental stewardship.

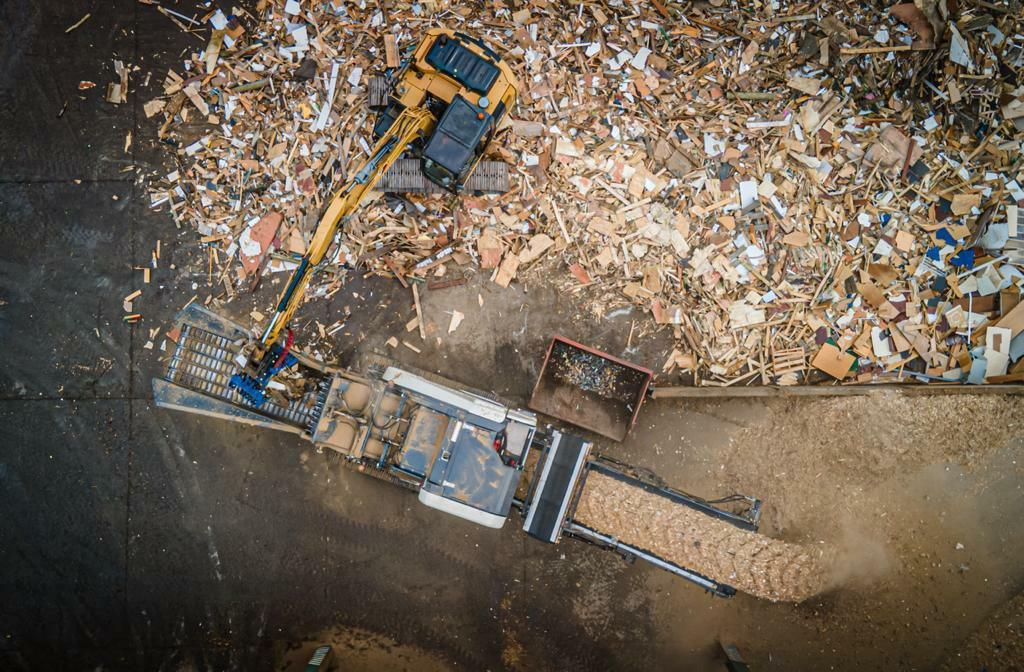

Rogaland Gjenvinning has tripled its wood processing capacity while reducing its diesel consumption and CO₂ emissions following the installation of a Terex Ecotec TBG 630E

Rogaland Gjenvinning has tripled its wood processing capacity while reducing its diesel consumption and CO₂ emissions following the installation of a Terex Ecotec TBG 630E

© Terex Ecotec

Since commissioning the TBG 630E, the company has achieved a 300 % increase in processing capacity compared to its previous diesel-powered model. As well as this threefold increase in output, the TBG 630E has also reduced bottlenecks and enabled faster, more reliable handling of approximately 25 000 tonnes of wood annually.

The transition to electric power has also delivered substantial environmental benefits. By eliminating the need for over 7000 litres of diesel each month, Rogaland Gjenvinning is now saving an estimated 18.8 tonnes of CO₂ emissions monthly, equivalent to more than 225 tonnes annually. These savings directly support the company’s mission to reduce greenhouse gas emissions and promote sustainable waste management.

The TBG 630E’s intelligent design has streamlined maintenance routines and reduced downtime with easier access via maintenance walkways and openings, faster workshop access, and simplified screen changes. These operational efficiencies have translated into faster return on investment and a stronger competitive edge.

As well as a threefold increase in output, the TBG 630E has reduced bottlenecks and enabled faster, more reliable handling of approximately 25 000 tonnes of wood annually

As well as a threefold increase in output, the TBG 630E has reduced bottlenecks and enabled faster, more reliable handling of approximately 25 000 tonnes of wood annually

© Terex Ecotec

Designed for medium to large-scale biomass and green waste processors, the TBG 630E combines two 200kW electric motors with a robust swinging hammer rotor. A further 90 kW electric motor provides the hydraulic power for the open-fronted feeder, discharge conveyors etc. This configuration enables exceptional throughput and consistent end-product quality, while its intelligent screen opening system quickly discharges metal contaminants to prevent damage.

Kjetil Friestad, CEO of Rogaland Gjenvinning commented, “The TBG 630E has transformed our operations. We’ve not only tripled our capacity but also significantly reduced our carbon footprint and maintenance workload. These improvements allow us to serve our customers faster and more reliably, while aligning with the values of an increasingly environmentally conscious client base. It’s a win-win for our business, our customers, and the planet.”