Wagner Magnete launches the largest non-ferrous separator in the company‘s history

A non-ferrous separator (NF separator) with special technical innovations is the answer of Wagner Magnete to the ever-increasing product flows in waste wood and bulky waste processing.

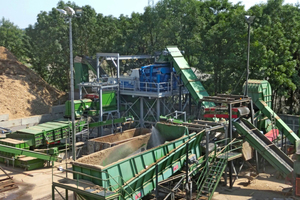

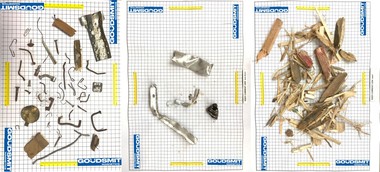

„The precision rotors of our new NF cutting-edge technology increase throughput by a whopping 50 % compared to the previous standard machines with a working width of 2000 mm. Thanks to the large working width, it is no longer necessary to divide the mass flow between the units. Bottlenecks, constrictions and critical interference contours in the material guiding can thus be avoided“, says Wolfgang Wagner, Managing Director of Wagner Magnete. First, Wagner magnetic separators withdraw the coarse iron from the material flow to enable mills to chop the wood into woodchips. Extremely strong magnetic drums made of rare-earth magnetic material subsequently remove all nails and screws released during comminution. Afterwards, the wood chips are fed to a non-ferrous metal separation.

The wood chips removed from the metal are often processed by chipboard factories, whose requirements are strict: in order not to impair the production processes, the metal content in the wood supplied must be extremely low.

Robust design

High operational safety

Low-maintenance design

Eccentric, adjustable magnet rotor

Very deep penetration

Maximum magnetic volume

Highly-coercive magnet material

Fast pole changing frequency due to 3000 1/min rotor speed

Effective residual iron separation by upstream connected neodymium magnetic drum