TOMRA enhances X-TRACT with Dual Processing Technology, multi-density channels and application packages

TOMRA Sorting Recycling has introduced a new-generation X-TRACT machine with innovative Dual Processing Technology which enhances final purity levels; multi-density channels to enable more precise classification and sorting of materials; and a broad range of application packages.

X-TRACT is best known for the sorting of Zorba (shredded mixed nonferrous scrap metals) into aluminum and mixed heavy metals but is now available in five different application packages: the E-Scrap, Organic, Wood, Aluminum, and High Power Pack. Each Pack optimizes the machine’s performance for specific sorting tasks by precisely tailoring sensor and X-ray set-up. Application packages also have tailored mechanical specifications, fine-tuned to the user’s needs. Some users, for example, need higher material throughputs than others, and some sort heavier materials.”

Dual Processing-Technologie and multiple density channels

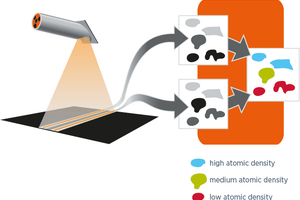

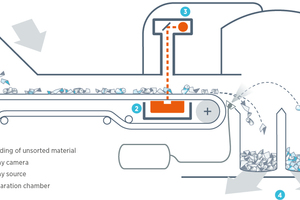

X-TRACT employs X-ray transmission (XRT) technology to sort materials according to differences in their density. Broad-band radiation penetrates the material to provide spectral absorption information which is then measured with a highly sensitive X-ray camera to identify the atomic density of the material, regardless of its thickness.

The Dual Processing Technology enables X-TRACT to distinguish between overlapping objects on the sorting line, a particularly useful advantage when lines are running higher throughputs. This advantage has been made possible by the development of sophisticated software, which can detect and prioritize between single object processing and area processing. X-TRACT is the only machine capable of this.

The introduction of multi-density channels is also a useful advance. Previous X-TRACT models sorted material according to two classes, separating it into high-density and low-density fractions. The new X-TRACT features multiple density channels, allowing a greater number of classes for separating materials according to density, with the maximum precision.

TOMRA has also improved X-TRACT with the new TOMRA ACT. This intuitive user interface enables the setting of several user-levels. TOMRA ACT is placed to optimize the sort and shows operators the most relevant real-time process data at a glance. This information improves monitoring and enables fast adjustments at any time, so the operator is always in control.