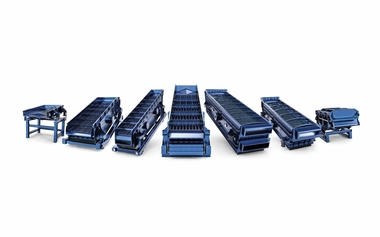

The “new” OSCILLA generation – continuing the story of success

On its 100th anniversary, JOEST presents a Flip-Flow update with minimal maintenance and less installation effort.

Operation

The OSCILLA Technology is based on that of a resonant system in which the dynamic screen frame is excited relatively to the body of the screen as a reaction to the directly excited screen body. The body of the screen itself is brought into oscillation by a standard unbalance motor or accordingly by a single or double shaft drive. As a consequence, the dynamic frame performs a linear motion relative to the screen body. The clamped screen mats are attached to the dynamic frame and the screen body via crossbars. As a result of the relative motion of the two systems, the mats are stressed and relaxed. The process is comparable to the effect on a trampoline. This way the particles are accelerated by up to 50 G and the screen mats do not clog.

Application

OSCILLA Flip-Flow Screens are suitable for the use in the Primary and Secondary Raw Materials industries. The OSCILLA screen is applied in the processing of household and industrial waste, shredder fractions, compost, wood, surrogate fuel, natural stones, ores, minerals and coal. The Flip-Flow Screens are ideal for bulk materials that are hard to screen due to their particle shape, inhomogeneous nature or have a high moisture content. Broken bottle glass is a typical material and contains varying amounts of organic material depending on the country and region. The inlet particle size of an OSCILLA Flip-Flow Screen typically lies between 0 – 80 mm depending on the material´s bulk density.

Advantages

The JOEST engineers designed the attachment of the screen mats to the cross bars with a special focus on maintenance friendliness: changing the mats is simple and quick. This long proven JOEST design is ideal even for applications with extremely high acceleration values. Additionally, the screening mats are installed very high up at the end of the cross bars to ensure an optimal sealing to the sides while simultaneously ensuring a maximal effective width. The combination of operational safety and efficiency of the useable classifying surface is another JOEST feature.

A big advantage of the OSCILLA Flip-Flow Screen is the high flexibility with the optional JOEST stroke control. The stroke is measured and combined with a frequency converter. That way the relative motion between the dynamic frame and the screen body can be held at a set value. Especially for machines that are located in an environment with extreme temperature variations, an automatic stroke control enables additional operational safety. The high flexibility is another advantage of a controlled Flip-Flow Screen. Feeding materials with different characteristics (e.g. variations in moisture content due to weather) can be processed by the same device by changing the machine´s parameters.

The “new” OSCILLA

The 2019 generation of the JOEST OSCILLA comes with the usual JOEST quality made in Germany. From a design point of view, the first thing that stands out are the Vibroblocks. These are located between the dynamic frame and the body of the screen. They absorb or pass on the system‘s resonant forces. This was JOEST‘s answer to client‘s request to come up with a robust, simple and cost efficient solution. The Vibroblocks are tested, long living and minimally sensitive to temperature variations. In case they must be change anyway, JOEST‘s engineers payed great attention to their easy accessibility and quick service. This is reflected not only in case of services by minimal down times but also in the final assembly of the OSCILLA.

Another innovation by JOEST in terms of manufacturing can be found in the design of the cross members. These are no longer manufactured individually for each machine type. Instead, they consist of specially developed profiles that simply have to be cut to length and fitted with a standard end-plate. Even the attachment points for the Flip-Flow Screen Mats are integrated. This way, the labour intensive alignment and bolting on of the individual parts to the cross members are eliminated. By leaving out parts on the cross bars there are now also less parts in the material flow that offer potential for wear or material sticking to them. Vibroblocks and cross bar innovations: cost-synergies that JOEST gladly passes on to its clients.

The “new” OSCILLA will be available in the known sizes from 600 mm to 2400 mm in width and a length of up to 9200 mm with an option of a single or multiple deck Flip-Flow Screen. In combination with conventional screen plates in the upper deck, you can get the best of both screening worlds in one application. Furthermore, with the modular design, numerous inlets and outlets can be attached without changing the base construction. For the most part the Flip-Flow screen avoids welding seams. Instead it uses bolts to permanently and securely connect its parts with each other.

The newest product development by JOEST intends to secure the OSCILLA Flip-Flow Screen‘s long-life cycle and minimize services. Just in time for its 100th anniversary, JOEST is happy to present its clients with an even more reliable Flip-Flow Screen and is hoping for a successful sales start of the “new” OSCILLA.

↓

Interview with Dr. Marcus Wirtz, Managing Partner at JOEST Group, on the company’s 100 years of history, and what role talent for innovation has played in it

recovery: JOEST is celebrating one hundred years of its existence this year. Have innovative flair and the continuous search for new solutions contributed to your company being able to look back on a long and successful corporate history?

Dr. Marcus Wirtz: The continuity with which we have established and expanded our portfolio has without doubt played an important part. Continuous growth and further development, and concentration on core topics – all of these are significant factors that have made JOEST the globally known company that it is today.

Our customers’ expectations have, of course, also changed in the course of time – the trend is toward ever larger machines, and mechanical screens are also getting bigger and bigger. We also built our largest mechanical screen – with a width of 5 m – in a double-deck version. Our main markets – Australia, the USA, Canada and South Africa – also exert a great influence, of course.

And the great competence of our engineers naturally also plays an important role – we have built them up in the individual national agencies, and they are not only masters of vibratory technology, but also of the upstream and downstream process stages. A good example of this is crusher systems: we do not manufacture these ourselves, but we do have to understand what happens in a crusher, what materials crushers need and what material comes out of a crusher.

recovery: To what sectors are these large mechanical screens supplied?

Dr. Marcus Wirtz: Above all, to the iron ore sector, and all sectors that process hard rock and minerals: gold ores, copper ores, lithium ores – we are very strong in these areas. In Australia we supply major mines involved in the getting of mineral resources using mining methods.

recovery: How has it been possible to assure, across such a long period of time, that the company and its employees maintains this spirit of innovation and such receptiveness to continuous further development? Does this originate from management or from the employees … how can this be secured across such a long time?

Dr. Marcus Wirtz: This always starts in our heads, ultimately all the threads must converge at central office, at headquarters. But just as important are the individual subsidiaries around the world, which are situated very close to the customer and have a feeling for exactly what the customers, and what the markets need right now. This is why we systematically develop subsidiaries around the globe.

And the qualifications of our employees are, of course, also very important. Our staff always come from the market, i.e., from the industries themselves, such as mining engineers, for example, people who have grown up in mining. And the impulses for our further development also always come from our markets.

recovery: One hundred years is a very respectable age for any company – how has JOEST evolved into what it is today, what were the most important milestones?

Dr. Marcus Wirtz: The first important factor is that we are a family- and owner-managed company. This enables us to ensure fast decision-making routes and spontaneity. But it is also possible to take entrepreneurial risks, and have the courage to develop further and position oneself internationally. This has put our company ahead for a hundred years. That was not always possible without setbacks, of course. But these can be overcome provided there is support from the company.

The most important milestones have been continuous growth and acquisitions. During the past twenty years our development has been definitively shaped by internationalisation, i.e., the setting up of subsidiaries and, in parallel, the acquisition of companies with technologies that complement our own.

recovery: How do you make sure that you retain a feeling for where the market is heading and what that market needs – does JOEST lead here, or does the company only react to market requirements?

Dr. Marcus Wirtz: No, proactive discussions with our customers are extremely important. This means that we have to have a presence, with qualified employees in the individual regions. We have highly competent managing directors in our subsidiaries, it is important here, above all, to also take account of special regional features. South America, for example, is different to Europe. Totally different structures. Listening is extremely important in this context, in order then to start being creative and power up development.

Here at our main location in Germany, we have our own development department, which then incorporates the corresponding feedback into its work. At the same time, we also founded in Australia a Competence Center for mining where the flows of information coming from our main markets in the mining sector converge.

recovery: What are the essential focuses of machine development?

Dr. Marcus Wirtz: Over these hundred years of development, we have established a very broad spectrum of mechanical screens for the primary and secondary sectors. These are now also equipped with smart control systems. Our range of drive technologies enables us to produce linear, circular and elliptical-motion screens. The necessary control systems are assembled in-house. And we are continuously further refining the mechanical screens themselves, the drives and the smart control systems. For us, a “smart control system” means, for example, that the screen itself detects that the material has changed, maybe it has a higher moisture content, and is able to react immediately by changing the parameters. This is also where we see the future.

recovery: At the start of July 2019, you celebrated the company’s 100th anniversary with the employees and their families. What makes JOEST and its employees special today?

Dr. Marcus Wirtz: On the one hand, the fact that we have a broad positioning in the various industries, are already specialists in vibratory technology, but can also offer turnkey solutions, vibrating trough feeders, chutes and structural steel – we can do all of these. We also perform the planning, design and engineering. Our employees are the most important foundation for the company, we also offer training, and we have around thirty-five trainees each year. We also have a very great depth of production here at our location.

recovery: What are your visions for the future?

Dr. Marcus Wirtz: One of our visions is a continuous process of growth – together with our customers and the markets. The decision has just been taken, for instance, to build a complete new plant in Australia, with more than twice the previous capacity, in order to meet growing demand and be able to expand into new market segments and industries. Requirements in the primary and secondary resources sector are becoming ever greater, and we will also be able to accommodate them in the form of all-in solutions.

The future is also, of course, in the field of Industry 4.0 – we already offer solutions for this, but we intend, naturally, to further evolve and expand these.

Another focus is drive technology. Here the emphasis is on service-lives, energy-efficiency and reduction of noise emissions …

recovery: What role will the structure of the family-managed company play in its future orientation?

Dr. Marcus Wirtz: We have short decision-making paths, we are extremely flexible, and we are not externally controlled. We can allow ourselves long-term innovations. In terms of orientation, we are always interested in the longer-view perspectives of our development, with a focus on the future and on our customers.

recovery: Dr. Wirtz, many, many thanks for this informative interview!

Technical data

Feed size: 0 – 80 mm

Drive: Unbalanced motor;

one or two shaft drives

Width: 600 – 2400 mm

Max. length: 9200 mm

Option: Single or multiple deck screen;

combination with conventional

screen decks

Industries: Primary raw materials;

Secondary raw materials

Applications: Household and industrial waste

Scrap, ASR

Glass

Compost

Wood

RDF

Hard rock

Ore

Minerals

Coal