The high-performance professional when it comes to metal shredding

High availability, high throughputs

The XR is robust and wear-resistant, making for a high level of plant availability and minimal downtime. The machine is particularly resistant thanks to a single-shaft shredding concept that delivers a pre-defined grain size in just one step, ensuring high throughput rates. The size of the output grains may be adjusted as needed by using a range of different screens. The combination of a slow-running, synchronous motor and a safety coupling protects the machine from damage, for instance caused by extraneous matter. A push bar transports light sheet metals to the rotor, pushing them down and thus improving throughput rates. An additional wear protection mechanism increases rotor availability and lowers maintenance costs.

Easy cleaning and maintenance

The XR shredder is particularly user-friendly. The exit door for non-shreddables is easy to open and clean before each batch, keeping contamination to a minimum. Spare parts are usually available within 48 hours and the remote maintenance option further ensures the smooth operation of the plant.

UNTHA Eco Power Drive

Minimum operating costs combined with maximum performance make the shredders of the XR series powerful partners for recycling applications. The energy-efficient „UNTHA Eco Drive“ concept lowers energy consumption by 75 % compared to standard diesel-hydraulic drive options. This saves metal-processing businesses a lot of money, protects the environment and lowers noise levels, thereby protecting the health of operators.

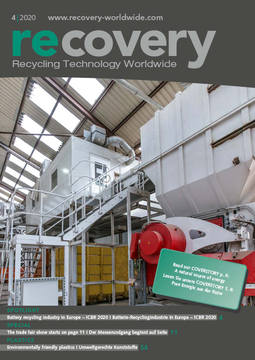

Mobile or stationary

Another important advantage of the XR class is that the machines are available in a stationary and a mobile version. This makes them particularly versatile and offers metal-processing firms maximum flexibility, as well as facilitating integration into existing plants. The overriding principle at UNTHA is to provide a tailor-made solution for every customer requirement. A big bonus of the Austrian premium manufacturer UNTHA, headquartered in Kuchl bei Salzburg/Austria, is that prospective clients may try out a mobile XR on their own premises and using their own material, thus really putting their future solution through its paces.

Clear decision in favour of UNTHA

Clients who have already been working with the XR metal shredding solution provided by UNTHA for several years are thoroughly satisfied with this solution: Paul Losbichler, Managing Director of Schaufler GmbH in Ybbs/Lower Austria, puts it like this: „We were really impressed with the XR3000C, in particular with the high throughput, great energy efficiency and low wear rate. All these factors made us decide to put our trust in this product on our path towards even more comprehensive recycling services. We highly recommend the unit and UNTHA.“