RecyclingAKTIV & TiefbauLIVE showcases state-of-the-art machinery and processes for demolition, construction, and recycling in action

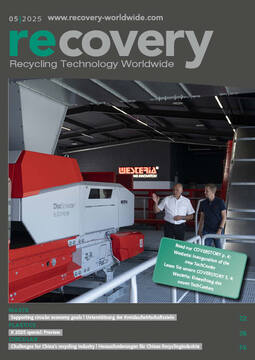

In October 2025, decision-makers and experts will be able to experience state-of-the-art machinery and processes for demolition, construction, and recycling in action at RecyclingAKTIV & TiefbauLIVE (RATL) at the Karlsruhe Exhibition Center. Ralf Nowak, managing director of the waste management company WEAG in Köngen, explains the inspiration he hopes to take away from the trade fair for his everyday business.

The increased use of recycled building materials can conserve scarce raw material resources and reduce CO2 emissions in the construction sector. The waste management company WEAG GmbH & Co. KG in Köngen near Stuttgart is making a regional contribution to this. Managing Director Ralf Nowak explains what he expects from the RATL demonstration trade fair from October 9 to 11, 2025, in Karlsruhe: “For me, RATL is right at the heart of the matter – with excellent, in-depth advice,” he says. “This trade fair offers us the latest technology and valuable inspiration for our operational practice.”

Business with material flows

As a certified waste management company, WEAG accepts single-type recyclables such as waste wood, construction waste, concrete, flat glass, mineral wool, and scrap metal, but especially mixed waste such as contaminated construction waste and mixed mineral construction waste. These are separated using magnetic separators and screening decks, among other things, and in the final sorting process, mastic asphalt and gypsum are extracted from the pure minerals. “This process is pure manual labor,” explains Ralf Nowak, “but it allows us to react very quickly to changing main and accompanying materials. Our core competence lies in collecting the mineral components and other recyclable materials completely and sorted by type and making them available to the processors.” The waste disposal experts do not shred the material, but separate it in several stages – from pre-sorting with the sorting excavator to screening into different grain classes. Coarse material with a grain size of over 150 mm goes directly onto conveyor belts for manual sorting, while the medium grain classes 8/45 and 45/150 are sent to magnetic separators and air separators for manual sorting. Fine material with a grain size of 0/8 or pure sand is removed using a tension wave screen. “Machines and equipment like this for our operational needs are on display at the RATL trade fair in Karlsruhe – and can be seen in action,” Nowak expects.

Focus on operational logistics

The raw material is delivered by builders and waste disposal companies, among others, some of whom are also shareholders in WEAG. After material separation, recyclable mineral materials are collected by recyclers, combustible material is thermally recycled, and the non-recyclable residue is sent to landfill. Wheel loaders and excavators are used for internal handling and loading of the sorted material. Standard and special attachments can be used to quickly extract specific fractions from the material and sort them by type. “All these equipment carriers and attachments can be found at RATL 2025 – partly at the exhibitors‘ stands, partly in the wood and biomass as well as scrap and metal action areas,” says Ralf Nowak. “We can view, compare, and evaluate the suitability of special equipment for our operations in a particularly realistic manner in the attachment arena – for example, waste pulverizers for separating the growing quantities of composite materials, as well as other shredding and sorting devices.” Accompanying technology such as spray lances and fogging systems for dust binding can also be found among the approximately 275 exhibitors, many of whom offer recycling solutions.

History and future in fast motion

WEAG has been operating waste separation and recyclable material recovery on its 7000 m² site in Köngen for exactly 30 years. Around 45 000 tons of material are processed annually, with 80 % of the output consisting of mineral substances. In addition to the use of machines, much of the work is still done by hand. “Robotics and AI for sorting do not make sense for us at this point,” says Ralf Nowak. “But we are currently setting up a system combining camera technology and AI. It records the volume of the material delivered on the truck‘s loading area and, together with the result of the weighing process, calculates the bulk weight – a good indicator of the proportion of valuable mineral fraction and a reliable factor for price classification.”

Insulation materials such as glass and mineral wool or foam panels, as well as modern composites, have become problematic. “Even though it seems almost impossible to separate these materials from the minerals,” says Nowak, “we are hoping that pioneering industry events such as RATL will send out a strong signal.”

Further expectations of the trade fair

“At WEAG, we live off waste, but we also want to show alternatives,” explains Ralf Nowak. “Basically, we can cleanly separate all materials that our shareholders and other suppliers bring to the factory premises. But it also has to be economically viable.” He expects valuable impetus for this from the RATL trade fair. In addition, landfill space is already scarce and will become even more expensive – and this will increase the pressure on all players. “We need to raise awareness among planners and tendering authorities that recycled material is an important product and that the legal framework for its marketing and use already exists” Nowak appeals. “I therefore see it as a task and opportunity for the trade fair to create a broad, open forum for knowledge transfer on circular construction and to expand the circle of trade fair target groups to include players upstream of the construction industry.”