K 2025 – Experience STEINERT‘s sorting technology for difficult plastic streams live

Black packaging, thin films and contaminated food containers are among the biggest challenges in plastics recycling. At K 2025, STEINERT will demonstrate how modern sensor technology and artificial intelligence can reliably sort even these difficult material streams and achieve a sorting accuracy of over 98 %.

Experience technology up close – on our exclusive tours

In addition to exciting insights at the trade fair stand, STEINERT is inviting visitors to experience sorting technology not only in theory but also in practice – on exclusive tours of the STEINERT Test & Development Center near Cologne or the RE Plano sorting plant in Bochum.

Tour of the STEINERT Test & Development Center near Cologne

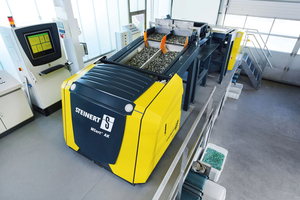

On three days of the trade fair (9, 13 and 14 October), shuttles will take visitors directly to the Test Center at the company headquarters. During tours lasting just under four hours, experts will demonstrate the AI-supported sorting programme Intelligent Object.Identifier (IOI), which UniSort PR EVO 5.0 uses to separate food-grade packaging from other plastic packaging, as well as precise flake sorting down to 0.5 mm with MSort AK. Participants will also have the opportunity to talk directly to their contact persons about specific projects and technical details.

Tour of the RE Plano sorting plant in Bochum (in cooperation with VDMA)

On K-Friday (10 October), a joint tour with the VDMA will take visitors to the sorting plant of Remondis subsidiary RE Plano – one of the most modern plants for lightweight plastic packaging in Europe. Here, sensor and magnetic technology from STEINERT is used on an industrial scale to sort pre-sorted packaging materials into recyclable plastics. All tours include shuttle service from the exhibition grounds

Technical presentations in the VDMA forum “The Power of Plastics”

In addition to live demonstrations and plant tours, trade fair visitors can also find technical inspiration. As part of the VDMA forum “The Power of Plastics” on 10 October, Nicolas Deleris (Segment Manager Plastics) will explain how state-of-the-art sensor technology can be used to efficiently separate plastics and obtain high-quality recyclates, while on 11 October Björn Lövenich (Head of Sales Waste Recycling Division / Steinert GmbH EMEA, India, Asia) will show how big data analytics can increase the performance and efficiency of recycling plants.

Hall 9, Stand E22