Pre-shredding prevents blockages in the baling press

Say goodbye to high energy consumption and rapid wear and tear on presses: Mechanical pre-shredding of packaging cartons optimizes internal material transport, saves energy, and reduces storage space.

The shredding of cardboard plays a key role in the efficiency of the entire disposal process. However, if channel balers or press containers become clogged and wear out more quickly as a result, automatic feeding can only be restarted through time-consuming and physically demanding manual intervention. Even without blockages, the machines often require a disproportionate amount of energy to press large, sturdy cardboard boxes, especially those with reinforced corners. In addition, cardboard boxes, especially packaging material, take up a lot of storage space. Carsten Zier, managing director of Udo Zier GmbH, a packaging specialist, was also faced with this problem. He came across a number of oversized and almost twice as expensive solutions until he contacted Erdwich Zerkleinerungs-Systeme GmbH. He invested in the EKZ cardboard shredder. Since the machine has been in use, Zier has benefited from significantly fewer malfunctions in the channel baling press.

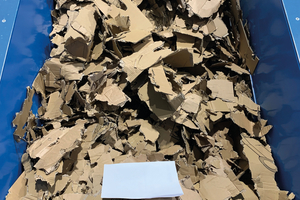

“It‘s that simple!” says Udo Zier from packaging specialist Udo Zier GmbH. Since June 2023, this company has been pre-shredding huge sheets measuring up to 2.40 m by 6 m using the EKZ cardboard shredder from Erdwich Zerkleinerungs-Systeme GmbH. The resulting DIN A4-sized pieces are then automatically fed into the channel baler. Thanks to the preliminary work done by the EKZ, the recycling process at Zier has become much more stable – without being slowed down by a clogged channel baler right at the start.

Zier recalls: “Our problem was waste paper or rejected sheets, which, due to their size, could not be fed into the automatic channel baling press, or only with great difficulty. This repeatedly caused disruptions in the automatic disposal process in our production.”

The EKZ: Slow feed, fast shredding

This is how the EKZ works: The machine‘s slow-running feed shaft feeds the cardboard to the fast-running shredder shaft. The resulting speed differences tear the cardboard apart. The machine also shreds fruit crates, Styrofoam packaging, and other types of packaging in this way. It does this reliably for years, because the shredder shaft blades are made of wear-resistant special steel.

The perfect machine for every challenge

Erdwich‘s mechanical engineers tailor each machine precisely to the specific requirements of their customers. At Zier, for example, the task was to efficiently shred particularly large cardboard boxes. In other cases, smaller objects have to be processed, which requires a reduced cutting length: In order to cover as large an area as possible, cutting lengths from 1.10 m to a maximum of 2.50 m are possible. These differences in length are made possible by the hexagonal rotor shaft, which is equipped with individually inserted shredder segments made of wear-resistant special steel. Depending on the expected tasks, the devices are equipped with the appropriate drive with outputs ranging from 5.5 kW to 7.5 kW.

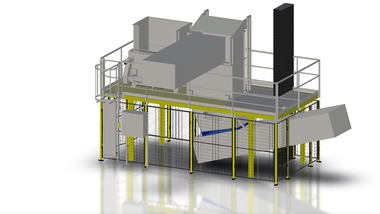

In the horizontal version, the EKZ is equipped with a flanged feed table including a safety rope switch for manual feeding. This configuration is used when the EKZ operates as a stand-alone machine. At Zier, however, the machine is used as part of a fully automatic disposal process. In such cases, where seamless integration into existing disposal lines is required, the EKZ is installed in a vertical design. For Zier, the EKZ was therefore precisely matched to the downstream systems.

Adhesive tape, high speeds? Other requirements, other solutions

In some companies, packaging with adhesive tape is a recurring problem. This often leads to tangles in the cutting unit. Especially in the area of corrugated cardboard sheets and other fine cardboard materials that fall out of the punching machines at high speed, a fast-rotating fine cardboard shredder (FKZ) from Erdwich is required.

The FKZ shreds materials into fine chips using a fast-rotating unit. A pneumatic extraction system then removes these chips and the resulting dust cleanly. With cutting unit lengths ranging from 1.3 m to 1.6 m, the FKZ can also be optimally adapted to individual requirements.

Fully automated process saves working time

When combining the EKZ cardboard shredder with the channel baling press, as used by Zier, the shredded cardboard pieces are fed into the channel baling press fully automatically. This means that the EKZ fits securely into the existing process. Since the Erdwich cardboard shredder has been in use there, employees can once again devote their working time entirely to their actual tasks without having to deal with additional disruptions.

Zier is constantly amazed by the performance of the EKZ: “The EKZ even shreds 3-ply heavy corrugated cardboard!” Energy consumption has been reduced because the channel baler no longer has to struggle with the extra-reinforced corners of the sturdy cardboard. Wear and tear on the channel baler has also been reduced because the rotating components and the motor are subjected to less stress due to the lighter workload and lower load. “Finally, the disposal process is running as planned!” Zier sums it up.