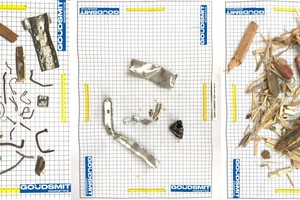

Mobile magnet system separates both ferrous and non-ferrous metals

The magnetic separator is easy to position in the right place and is designed for coarse bulk flows such as shredded wood. Both ferrous parts, such as nails, screws, staples and hinges, as well as non-ferrous parts, such as door handles and strips, must be removed from this waste. The result is three separate material flows – ferrous, non-ferrous and clean (inert) bulk material – which is suitable for reuse. In addition to wood, the mobile machine is also suitable for construction and demolition waste, refuse-derived fuels and industrial waste, among other things.

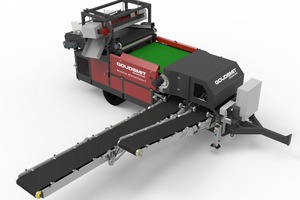

Operation

A spreading plate provides the infeed and breaks up the bulk. This distributes the material nicely over the angled feeder belt. This monolayer is the ideal situation for use of an overbelt magnet that pulls all the iron parts out of the flow and, if desired, diverts them to the left or right. After the iron parts are removed, the bulk is transported to a 2-m-wide eddy current separator. There a powerful 22HI rotor separates the non-ferrous metals from the bulk material.

The metal separator has a capacity of 100 m3/h and is fed via a 2000 mm wide feed belt with speed control. The sturdy ferrite overbelt magnet contains material guide funnels; The eddy current separator is a 2000 mm wide 22HI rotor with 3000 revolutions per minute. Both conveyor belts are hydraulically height adjustable. The mobile unit is built on a single-axle trailer and suitable for public roads.

Stand: F 356