Innovations ensure speed, precision and flexibility

Westeria will be presenting innovations and further developments at IFAT that are designed to significantly increase speed, precision, cost efficiency and flexibility in the processing of residual materials. The focus will be on the WeKea® system, which increases efficiency and speed in the project planning and delivery of high-quality conveyor belts, the use of artificial intelligence in distribution systems, and the new AirLift® move mobile machine, which effectively removes ultra-light materials such as film from compost, for example.

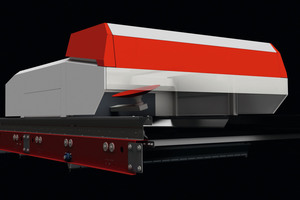

Conveyor belts configured and

dispatched at lightning speed

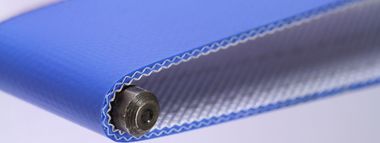

In the area of conveyor technology, Westeria presents the WeKea® conveyor belt system. This manufacturing and distribution system, which is unique in the industry, combines lean processes, digitalisation and automation as well as standardisation and serial production of entire assembly modules to make the use of high-quality conveyor technology easier and more profitable. With the WeKea® product configurator available online, customers can configure the belts individually on their own and within minutes. A quotation and 3D drawings are then automatically made available for download. Modules produced to the highest quality standards that are available from stock shorten delivery times. In addition, the modules are designed to minimise the required transport capacity and thus the delivery costs. If this compact shipping method is chosen, the staff can quickly and easily assemble the belts on site with the help of pictorial instructions.

Managing Director Felix Poth sums up positively: „We had to overcome some reservations at the beginning. However, the fast and efficient handling of our WeKea standard, which can cover up to 90 % of the conveyor technology in a plant, was always convincing in the end. For special requirements, the belts can be adapted as required as a customised version.“

Due to the success of this concept, Westeria has now also included the ChainCon® chain belt conveyor and the PlateCon® slat conveyor in the WeKea system. Numerous experiences from a wide range of customer applications have gone into the technical revision of these conveyor belt types. The result is an extremely robust, particularly maintenance-friendly conveyor system.

DiscSpreader® automove spreads

with optimal uniformity

For the first time, the company from Westphalia is presenting the results of a joint project with the Technical University of Cologne that has lasted for several years. In a revision of the well-known material distribution system DiscSpreader®, Westeria has taken advantage of the use of artificial intelligence (AI) to react automatically to varying material flows and to ensure a constantly uniform distribution. The result is the space-saving DiscSpreader® automove, which is being presented in operation for the first time at the exhibition stand and can be mounted directly on any type of conveyor belt. „A camera detects and evaluates the material distribution on the belt. The AI learns independently with this data and automatically selects the optimal alignment of the disc,“ explains Poth. A consistently good material spread is essential to optimally prepare plastic, glass, wood, compost, scrap, slag, waste or any other type of bulk material for subsequent steps such as NIR sorting or windsifting. This now eliminates the need for personnel to make manual readjustments when the material flow changes.

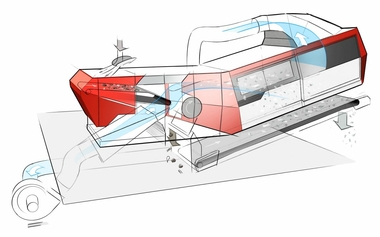

Removing impurities from biomass on site

In the field of mobile windsifting, Westeria will be presenting the AirLift® move as another new development on the outdoor exhibition area between Halls B5 and B6. This mobile machine is specially designed to meet the high demands of compost processing. Equipped with a hook-lift carriage or wheeled chassis and coupling, the ultra-lightweight separator works wherever it is needed. A bend in the SpeedCon® high-speed belt lifts the material slightly and enables efficient and precise extraction of light components at this point to safely meet the specifications for the permissible plastic content in the compost. The AirLift® move complements Westeria‘s field-proven portfolio of windsifters, which includes the traditional, stationary AirLift® as well as the AirBasic® mobile machine and the stationary AirStar® sifter.

www.westeria.de

Hall B6, Stand 329/428