Inauguration of the new TechCenter

In 1956, Hermann Westbrock founded Maschinenfabrik Westeria in Westbevern. At that time, the product portfolio included articulated conveyor belts with adjustable articulation angles, which were mainly used in agriculture. In 1986, Werner Knapheide joined the management team, and Westeria Maschinenfabrik was renamed Westeria Fördertechnik GmbH. The construction of conveyor systems for the recycling industry increasingly became the focus of the company‘s activities. At this time, Westeria also began pioneering work on the development of the first modern cross-flow air separators, which laid the foundation for a completely new generation of separation technologies.

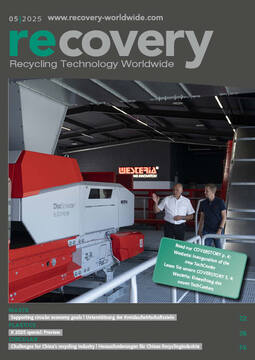

Another milestone in the company‘s history is the inauguration of the new TechCenter, which took place in September 2025. After 10 years of intensive use, the old technical center was closed, demolished except for the outer walls, and replaced by a state-of-the-art new plant with the latest equipment. “With the new TechCenter, we are setting a milestone for the recycling industry. Our customers not only receive state-of-the-art technology, but also reliable performance records for their individual requirements,” emphasizes Felix Poth, Managing Director of Westeria.

The recovery team had the opportunity to visit the new TechCenter in advance and was impressed by the customer-friendly equipment and modern digital technology.

In conversation with Hanno Jenkel, Head of Marketing at Westeria, and the editor-in-chief of recovery, Dr. Petra Strunk, the focus was on the development of the Westeria company and the design of the new TechCenter.

recovery: Westeria has been around for over 60 years, which is a long time for a company. Can you briefly outline its history?

Hanno Jenkel: I‘d be happy to. The history of our company dates back to the 1950s. At that time, industrialization was not yet very pronounced in the Münsterland region, and many companies originally came from the agricultural machinery sector, including Westeria.

We have been working with wind sifters since the 1980s. That‘s when we developed our first wind sifter. It was still quite simple in design but already followed the principle of a cross-flow sifter: a stream of air blows light materials out of a heavier material stream. Air is blown in from below, across the direction of material feed, causing the material to fan out.

recovery: What equipment and materials were the focus at the beginning of the company‘s history?

Hanno Jenkel: As I said, we have our roots in agricultural machinery manufacturing. For example, we manufactured conveyor technology for straw bales that could be transported to the upper floor of a barn. Some of these systems are still in use today – we even receive spare parts requests for them from time to time.

Later, we expanded our portfolio to include trailers, for example – both horse trailers and smaller caravans with folding tents. So, we were quite versatile.

recovery: When did Westeria take the step into the recycling sector?

Hanno Jenkel: With the development of the recycling industry, new requirements arose. Customers had specific separation problems and asked us for help. This led to the development of our first air separator at the end of the 1980s. At that time, a lot of things were done on demand: a customer came to us with a problem, and we worked together to develop a solution. Many developments arose from customer requests.

recovery: For which material groups did Westeria build the air separators at that time?

Hanno Jenkel: In the beginning, the main focus was on separating construction waste. With our mobile wind sifter, a cleaned stone fraction could be obtained directly on the construction site.

recovery: How have wind sifters developed over the past 40 years?

Hanno Jenkel: We started with really simple devices, some of which still had wooden cladding. Today, with over 35 years of experience, we are talking about highly sophisticated technologies. We carry out flow analyses and control every air movement in our machines.

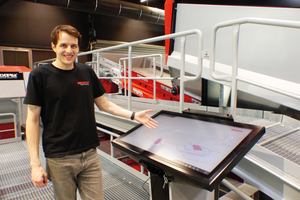

Every material behaves differently, every separation task is unique. At the same time, it is becoming increasingly difficult for our customers to recruit experienced specialists. That‘s why our devices must be easy and quick to adjust to any material. In the past, this was done with tools or a crank – today, it‘s fully electric at the touch of a button thanks to our new intuitive controls.

recovery: Today, many things happen automatically at the touch of a button. What was the main reason for converting the air separators to the revised control system?

Hanno Jenkel: On the one hand, as I said, because skilled personnel are becoming scarce. The machine must be able to be adjusted quickly, without lengthy training. At the same time, the requirements for throughput and purity have increased. Theoretical test results are not enough if they cannot be implemented in practice due to complex operation.

recovery: One of the latest developments in the field of air separators is the AirStar evolution. Can you tell us a little more about it?

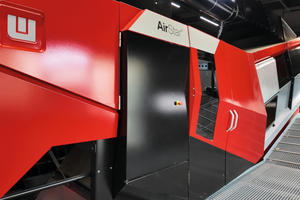

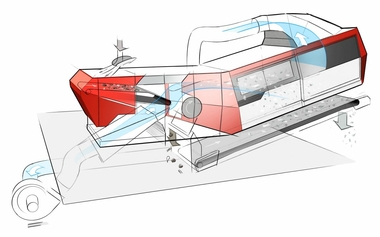

Hanno Jenkel: The AirStar evolution is our latest generation of air separators, which was unveiled about a year and a half ago at IFAT in Munich. It has a completely new control system that allows all parameters – separation drum, conveyor belt, nozzle angle, and air velocity – to be set at the touch of a button.

recovery: How can customers determine the optimal parameters for their material and separation task?

Hanno Jenkel: Before purchasing, customers can test their own material in our TechCenter and determine how best to separate it. In fact, customers from all over the world come to our TechCenter. We work with the customer in advance to design possible separation targets and plan the appropriate tests. The aim is to separate the fractions as sharply as possible with the highest material throughput and overall high efficiency.

recovery: How does such a test work?

Hanno Jenkel: Customers send us one or two big bags of their material. We process it in a cycle until we have found the optimal settings and parameters. The customer is usually on site to see the results. We save the parameters as a “recipe” in our system. When the customer receives the machine, these values are already stored as a possible program – they can start immediately.

recovery: Why was the construction of the new TechCenter started at this particular time?

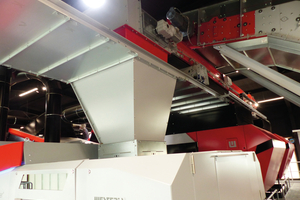

Hanno Jenkel: We wanted to showcase both the single-drum version and the brand-new DuoDrum version with two drums. The latter not only separates into light and heavy fractions, but also into a medium-weight fraction. To showcase the new DuoDrum version, we needed more space in the TechCenter and a new steel structure.

Now we have been able to accommodate both versions as well as additional units such as the completely redesigned AirLift in our new building. The test facility is modern, compact, and customer-centric. The integrated video system allows transparent monitoring of the separation results of all three lines. Our customers can now do more than just carry out tests here. We bring our solutions to life and let customers see the numerous innovations for themselves.

recovery: You just mentioned the AirLift. What does it do?

Hanno Jenkel: The AirLift is an overband foreign material removal system that can separate very light materials with very high separation accuracy from materials with very similar density properties. These can be, for example, films from compost or PP labels from PET bottles.

recovery: Are there any other devices in the TechCenter?

Hanno Jenkel: Yes, for example, the DiscSpreader automove, which uses AI to distribute the material optimally on the belt. This is important so that wind sifting or other sorting processes can work optimally. We also have classic DiscSpreaders without AI, depending on the application and requirements.

In addition to the sorting equipment, we are showcasing our conveyor technology – robust chain belt conveyors with automatic chain lubrication – and bunker systems such as the MultiFeeder, which can temporarily store material and feed it in measured doses.

recovery: What is special about your conveyor technology?

Hanno Jenkel: Conveyor belts may seem unspectacular, but small details make a big difference. We put the same energy into developing our conveyor technology as we do into our highly complex wind sifters. Our designs prevent wear and tear, reduce maintenance costs, and significantly reduce downtime. Customers really appreciate this because it makes plant operation much more efficient.

recovery: How do you see the role of the TechCenter in the future?

Hanno Jenkel: For us, it is a central meeting place for the recycling industry. Here, customers and interested parties can experience our technology live and develop solutions together with us. Above all, the TechCenter is an essential tool for testing materials and giving customers a feel for the technology. We build trust and position ourselves as a reliable partner for joint projects.

recovery: Thank you very much, Mr. Jenkel, for these very interesting insights.

The AirStar evolution

at a glance

NotusAir®

The innovative NotusAir® air separation system uses customized components to enable precise control of the air flow, which is the key to optimal separation results. The frequency-controlled fan mainly uses process air, which can be returned without material using a specially designed extraction hood. This eliminates the need for a separate filter system.

The air system reduces energy consumption and noise pollution by over 30 % compared to conventional methods and allows high-precision separation thanks to scientifically developed air flow analyses.

Central automatic parameter setting

A combination of movable separation drums and a vertically adjustable feed belt, supplemented by the adjustment of the nozzle angle and pressure control, enables highly accurate adjustment of the separation process via touchscreen. The settings can be saved and recalled in the newly designed control system.

Flexible extensions

The AirStar evolution is the only air separator that can be equipped with the patented DiscSpreader distribution system. This reliably optimizes material distribution.

Additional separation fractions can be combined thanks to the DuoDrum system (with a second nozzle and second separation drum) or AirLift add-on. This allows the material to be separated into up to four fractions with just one machine.