New PU conveyor belts for recycling applications

Nitta has expanded its product line of thermoplastic polyurethane (PU) conveyor belts. The material is exceptionally resistant to grease, oils and chemicals. The PU belts are highly flexible, easy to clean and have an extremely long life. Thanks to a unique new production machine, Nitta can now manufacture a wider range of PU belts with widths exceeding 3 m. The PU conveyor belts are ideal for conveying tasks in recycling as well as in food, logistics, agriculture and industrial applications.

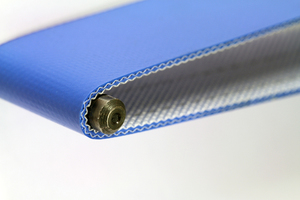

With a thickness of only 2.35 mm, this belt is oil and fat resistant, flame retardant and very durable. “The customer has four belts connected, of which at least two are continuously in operation,” Vrieling explains. “Each endless belt is 12 m long and 2700 mm wide. In this case the transported material is mainly recycled paper and cardboard. With speeds of 4 to 6 m/s the capacity is high. Especially the homogenized structure of the PU belt means a substantial increase in life-time. In this application the belt has been running over six months now, which is multiple times the lifespan of previously used PVC belts.” Also in so called non-ferro-separators, this PU belt can be used effectively in combination with magnetic drums to separate, for instance, metal from household waste and glass recycling sources.

In conveying recycling material, the belt material must be chemically inert and there must be an option for fitting sealed edges. Nitta’s new thermoplastic polyurethane material excels through its exceptional resistance to grease, oils and chemicals. Favourable properties of the new PU belts are furthermore bet-ter wear resistance and a lower coefficient of friction, which is desirable for applications with accumulated products on the belt.

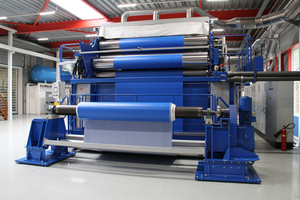

The new machine in Nitta’s production facilities in Alkmaar presses and homogenizes the cover mate-rial with calendar rollers. This results in a constant and compact structure. The homogeneous structure is a significant advantage in operation because there is less contamination and easier cleaning. This is very important to reduce the downtime of conveyors and consequently the entire production line.

With the new production machine, thinner PU belts can now also be made, which has the advantage that the belts can run over „knife-edges“ with an even smaller diameter. For single ply belts such rollers can have diameters as small as 4 mm. These thinner belts are more flexible, have a more favourable force-elongation ratio and the increased adhesion prevents delamination of the layers. Additionally, jointing will be much easier with this material.