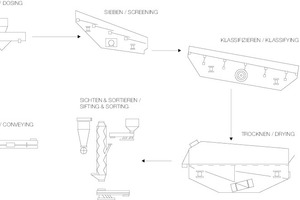

Dosing, screening, drying, sifting and conveying with JOEST machines

Recycling is a growing market – especially in glass recycling new plants are currently arising or existing ones are updated and upgraded. JOEST is an expert for vibratory equipment conveying and processing bulk materials. As such, JOEST offers plant manufacturers customized solutions for glass recycling. With dosing, screening, drying, sifting and conveying, the company covers five fundamental processing steps in a plant.

Thanks to the continuous development of standardized components and subsystems, the JOEST competence center recycling in Duelmen can assist each client with the individual configuration of their plant layout, especially regarding the procedural design of the individual processing components.

The challenge of wear and tear

JOEST covers a wide spectrum of applied technologies throughout the glass recycling process and simultaneously goes in depth with various versions as well as the corresponding periphery. The individual components are specifically designed for the demands of each industry and size, performance and features are determined by the client. The operational availability of the plant is very important. In particular the high wear resistance, thus the low abrasion of plant components plays a big role in Glass Recycling since glass brakes and is one of the most abrasive materials. Using highly wear resistant chromium carbide plates or special ceramic, the machines set standards and ensure high runtimes and yet low maintenance costs.

Dosing – with an innovative drive

From bottle caps and labels to cardboard and plastic: Glass waste can contain up to 50 % organic and waste materials. Depending on this composition and the final desired quality of the recycled material, a variety of sorting processes are necessary. The first step is to convey and dose the glass waste out of the hopper. JOEST magnetic feeders are ideal for such an application, since the feed rate is continuously variable and after being shut down, the machine stops immediately. In addition, the JOEST Hopper Discharge Feeders use an innovative, self adjusting JM-Magnetic Drive. With relatively high amplitude in combination with a comparably average vibration frequency, this drive system results in an efficient discharge. For their particular application, different parameters such as hopper pressure and geometry, grain size, ease of flow, moisture and tendency to bake-on must be considered. The optional covers and discharge hoods are also specifically designed for Glass Recycling. The drive´s self learning mode, enabled by the digital control unit, is as easy to maintain as it is economically efficient. This JM-Drive is an exclusive and unique JOEST product in the world market.

Pre-Screening – via Rod Finger Screen and Air Separation

Special JOEST Finger Screens pre-classify the glass waste into cross cuts between 10 and 40 mm grain size. The high acceleration rates and oscillation of the fingers loosen the material on the screen deck. They also ensure a near clog free screening process.

Fine fractions are screened out, coarse grain continues on to a crusher. In another processing step, the JOEST Air Vibe separates the first material flow and sorts out the coarse light weight fraction like foils or paper for example.

Screening – with the OSCILLA Flip-Flow-Screen

The JOEST Flip-Flow-Screen is designed for inhomogeneous or moist and thus difficult to screen materials. Particularly glass waste has varying levels of contamination with organic material, depending on the country and region it originates from. Here, the OSCILLA Flip-Flow-Screen provides ideal preconditions with a feed grain size of 0 to 80 mm. With its trampoline-effect, this special process prevents the product from sticking on and near-mesh grain from getting clog the sieve. The elastic screen mats which are fixed under tension with the traverse mutually beams and thus the dynamic frame and screen body, are decisive to the process.

The low maintenance is just as beneficial. Changing over the mats is quick and easy to do. In the newest OSCILLA generation, JOEST implements viroblocks between the dynamic frame and the screen body, following the demand for a simple, cost efficient, yet robust solution. The traverse beams also feature special profils to ensure flexibility and efficiency. They are simply cut to the desired length and bolted to the machine body.

Drying – via Fluidized Bed Dryer

The raw material in Glass Recycling contains about 7 % moisture. This moisture sticks to the product and complicates processing it. A drying stage eases further processing. For this purpose, JOEST uses a Fluidized Bed Dryer. With airstreams of more than 150 °C, it reduces the moisture level to a target value of 1 %. Thanks to the special design and layout of the air distribution chamber(s), the air passes evenly through the material and thus results in an equally even drying result. The conveyance within the dryer occurs via micro throwing motions, which are characteristic for vibration conveying technology. Amplitude, frequency and throwing angle are adjusted individually to the application and machine type. Additionally, air outlet hoods are available and follow the motion of the machine. JOEST delivers anything from the machine alone all the way to the entire drying plant including air handling equipment, air filtration, ductwork, steel construction and electrical control unit.

Sifting and sorting – via Zig-Zag

Inside the Zig-Zag Sifter, a multi stage separation of organic material from the individual pre-classified fractions takes place – the goal is an entire elimination of pollution from the raw material. In order to achieve this, the raw material is fed into the zig-zag shaped sifter-channel through an air-tight feeding mechanism. After the Multi Cross Flow Sifting Process, the light weight fraction separates itself from the heavy fraction. The Zig-Zag Sifter is also adapted to the glass material in abration intensive areas. Thus the JOEST Zig-Zag Sifter uses a Vibrating Trough Type Feeder, as opposed to a Rotary Feeder. This results in an even distribution across the width of the machine and feeding of the machine, whilst keeping the wear resistance high. Here too, JOEST offers the complete system with air handling equipment, used air filtration, pipelines, steel construction and electrical control unit.

And time and time again – Conveying

Depending on the glass recycling plant, there are different demands: Covering distance, feeding and distributing. For this, JOEST offers the matching drive technologies, like for example Unbalanced- or Resonance Vibrating Trough Type Feeders. All Trough Type Feeders feature an abrasion resistant lining and can be configured as dust tight if the client wishes so. In general, conveying stretches of up to 80 meters with a single machine are possible. Appropriate solutions for shorter distances with difficult installation situations can also be carried out.

Questions about glass recycling –

Dr. Marcus Wirts, managing partner of the JÖST group, answers

Dr. Marcus Wirtz, managing partner at JÖST group, examined interesting system solutions and – not only technical – challenges in glass recycling in an interview with the editor-in-chief of the recovery journal, Dr. Petra Strunk.

recovery: Glass can be repeatedly recycled, and the energy input required in the production process can also be significantly reduced when end-of-life glass is used. But only provided the end-of-life glass is also correspondingly prepared. What is most important here? And what is the attraction for Jöst in being so active in the field of glass recycling?

Dr. Marcus Wirtz: Jöst has been working in glass recycling for more than thirty years. The company is not a plant builder, but supplies all the main components for glass sorting, with the exception of the actual sorting units. These components include various types of mechanical screens, conveying equipment such as vibrating-trough feeders, for example, and machinery for air separation technology, which has greatly gained in importance recently, thanks to intensified development work - on zig-zag classifiers, for example.

And what is now so special about glass recycling? This field has developed further and further, and with high speed, both in Germany and globally. Where, initially, it was mainly a question of relatively simple sorting by colour, with accuracy not really playing such an important role, the demands made on sorting are now becoming ever greater. The core technology, optical sorting, operates at high speed, and it sorts by colour with great accuracy, down into the 2 to 3 mm particle-size range. It also eliminates other non-glass contaminations. These capabilities have, simultaneously, resulted in the demands of glass-industry customers growing significantly. And, not least of all, customers‘ demands on glass quality have also risen in parallel.

recovery: What are the special challenges of glass recycling?

Dr. Marcus Wirtz: Glass is by far the most wear-intensive material. That‘s a very important point, especially for vibrating-trough feeders. Correct design and appropriate protection against wear makes it possible to achieve much longer life times. This is not just a question of protecting specific material elements, but also of achieving the lowest possible level of abrasion by means of corresponding design provisions. Wear plays, of course, an even greater role in air separation, in other words, in zig-zag classifiers and cyclones, because there you have high air velocities combined with fine particles. This combination acts like a sandblaster, which will cause incredible wear. We have optimised our systems across decades – particularly the design of the piping, pipe routing, and the feed to the cyclones – and this has enabled us, with modified geometries and additional wear protection, to significantly minimise wear.

recovery: Jöst equipment can be found around the world. What is Jöst‘s position internationally?

Dr. Marcus Wirtz: We do not operate as plant engineers, but we do supply many of the main components for glass recycling. Our systems are also very well known internationally. Jöst machines have a very strong presence in China, the USA and Australia, in particular. End customers are familiar with our technology and value its quality. In addition, we have a worldwide local presence, with local manufacturing, wearhouses for spare parts and services on all continents which provide after-sales service for our systems. In some cases, we also produce locally.

recovery: What have been the most exciting projects already completed by Jöst? What special demands did Jöst encounter on these projects?

Dr. Marcus Wirtz: For the largest glass recycler in the USA we have equipped very many of these plants with Jöst machines during the past 15 to 20 years, for example.

In addition, our projects have become ever larger during the last few years. In the recent past, we have increasingly been involved in projects that could claim to be the world‘s largest glass-recycling project. At the moment, this alternates between the large markets of the USA and China. Here, the mass flows themselves are, of course, a challenge, the equipment is getting larger and larger, but the same efficiency is demanded.

recovery: Do you notice geographical differences in glass recycling around the world, and how does Jöst react to them?

Dr. Marcus Wirtz: It is, naturally, something quite different, if I collect waste types separately in Germany. Even there, of course, there is cross contamination, but the quantity is not even comparable to a single-stream waste flow, where the different types of waste converge with no sorting at all. Separate collection always generates the best sorting results. Where other collection policies apply, like in India and Southeast Asia, for instance, the feed material is much more inhomogeneous, and does not permit corresponding waste-type purity.

recovery: Does this have implications for the system concept?

Dr. Marcus Wirtz: Even at Jöst alone, this has resulted in optimising our zig-zag classifier and other air separators for glass recycling. These components were previously not used at all in this sector, because there were no, or much less, organic contaminations in the end-of-life glass, or also because the glass was not recycled to such high quality standards. Customers‘ requirements on the recycled glass are now so high that they will only accept higher-quality end-of-life glass. And in the case of single-stream waste, in particular, one vital task is to remove the organic constituents right at the start of preparation. This is why we have optimised our classifier systems, and the zigzag classifier, in particular, specifically for glass recycling. Likewise our screening technology, which separates the fines fraction out of the flow of waste. One particular challenge is found in moist fractions for which, above all, our vibrating screens, such as the OSCILLA Flip-Flow-Screen, for example, above all, are used.

We observe that glass recycling is increasing in volume globally. Less and less can, and should, be landfill dumped, and the recycling rates demanded are rising; primary resources are also becoming scarcer and more expensive, which is why there is ever greater demand for high-grade secondary resources that have been prepared to a high quality level. And sorting technology itself is, of course, also continuously improving.

recovery: From plant engineer to recycler – what, in your opinion, are the most important tips in the planning and operation of a glass-recycling facility?

Dr. Marcus Wirtz: This is an important question for us ourselves, this relates, very specifically, to screening technology. How can I optimise the feed and pre-sorting of the material? Older plants that are now upgrading focus, above all, on the organics constituent, a fraction which must be removed from the flow of glass at the very start of preparation. Air separation is then added to mechanical screens to solve this problem. These are precisely the topics that we are working on, and they show a positive trend for us.

recovery: A look into the future – how do you see the upcoming development of glass recycling and the technology needed for it?

Dr. Marcus Wirtz: I have a very positive view of the future, I perceive potentials for expansion, globally – and also in Eastern Europe, there is a need there to catch up. Even now, during this Corona crisis, capacity utilisation in the recycling machinery sector at Jöst is very good.

Around the world, there is a rising trend for the use of glass instead of plastics. It will also be necessary, for this reason, to recycle correspondingly more glass. We are focussing on the optimisation of systems, even better separation, higher system availability, longer equipment service-lives. In glass recycling, we are talking of a mass product for which a separation efficiency just one half of one percent higher makes a difference in the calculation, with system availability also improved and maintenance costs dropping again by a couple of points. This means much better profitability and cost-effectiveness for the system. So we also see this global trend, since the yield of end-of-life glass will become ever larger and the countries of the world will increasingly ask themselves how they should handle their waste flows and what can they make from them.