SENNEBOGEN launches electric material handler with battery technology: the new 817 Electro Battery as the first model of a new machine concept

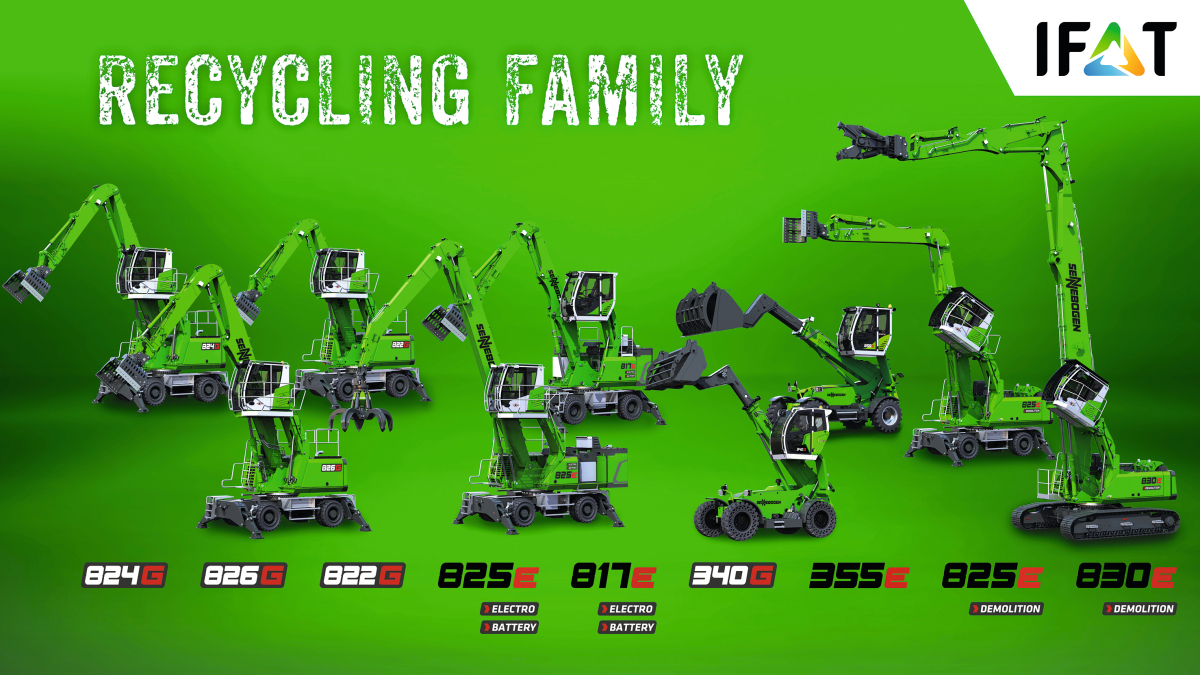

15.06.2022Useful technology for maximum CO2 savings and flexibility. The 817 Electro Battery battery-powered electric material handler is the first of the freely movable battery-powered models that SENNEBOGEN will be adding to its tried-and-tested electric range in the future. Thanks to dual power management, these models continue to offer all the advantages of cable-based electric material handlers, combined with total freedom of movement. Completely safe, comfortable and fully mobile around the clock with zero emissions – a new technological milestone for the industry.

With the launch of the new 817 E Electro Battery battery-powered electric material handler, SENNEBOGEN is expanding its electric range with freely movable models

With the launch of the new 817 E Electro Battery battery-powered electric material handler, SENNEBOGEN is expanding its electric range with freely movable models

© SENNEBOGEN

Emission-free electric material handlers have been available in wired form for many years. For over 30 years, SENNEBOGEN has been building electric material handlers, which are used stationary or with limited mobility due to the cable, and provide a solution for a wide range of applications. Pure battery-powered devices already on the market have proven to be disadvantageous so far due to the limited operating time of the batteries. Not so with the new SENNEBOGEN 817 Electro Battery: the new mobile electric material handler with battery technology combines the advantages of both solutions. With the SENNEBOGEN battery-powered material handler, you can continue working even when it is connected to the mains power for charging.

In mains operation, dual power management ensures that the power supply from the mains is used for the work movements, while the excess power fed in also recharges the batteries so that the machine can then work independently again. With an assumed 2000 operating hours per year and energy generation from renewable energy sources, the battery-powered material handler saves an average of 31 800 kg of CO2 per year compared to its diesel-powered counterparts – and with equal freedom of movement. In future, the battery option will be available for the entire electric series of the 817 to 825 models.

The freely movable models perfectly combine the advantages of stationary electric and battery-powered material handlers

The freely movable models perfectly combine the advantages of stationary electric and battery-powered material handlers

© SENNEBOGEN

Dual power management: Zero-emissions mobility without limits

The battery-powered version of the popular SENNEBOGEN 817 E electric material handler with 9 m reach and 18 t operating weight thus combines the advantages of two machine concepts: If the material handler is connected to the mains, it uses the wired power supply for the work movements without restricting the freedom of movement of the uppercarriage and equipment. Because the charging power is supplied to the undercarriage, the machine can continue to swivel and work 360°. If more power is supplied to the machine than it consumes, this is used to charge the batteries at the rear. If the mains connection is disconnected, the 817 Electro Battery automatically detects this and works autonomously in battery operation with the same performance data. Depending on the power requirement, the battery pack enables working times of six hours without recharging.

The great advantage of dual power management then comes into play once again: if the machine is working in a working position for one hour, for example, it can be conveniently connected to the power supply via a standardized CE plug and charged without having to stop work. The capacities of the battery are easily and flexibly charged so that the machine can be operated continuously over a complete shift and does not need to be switched off for charging.

Practical battery technology for every operation, combined with proven large-scale series technology

The machine also impresses with its practical design. Thanks to the CEE 63 A connector system, the 817 Electro Battery can use the existing infrastructure of an industrial company. Investments in expensive charging stations can be avoided thanks to the 44 kW on-board charger. Charging the batteries at any location is also an option, as a simple industrial socket is sufficient. Another advantage of a battery-powered electric material handler: Current peaks when working with the machine can be avoided via peak shaving, i.e. if more power is required, e.g. during combined movements and a full grab, this can be covered by the battery. The connected load is thus reduced to 44 kW without further restrictions. The integrated power electronics also ensure a gentle motor start that is particularly gentle on the mains power grid.

With the wealth of innovative drive technology, SENNEBOGEN continues to rely on the proven large-scale series technology that has always characterized the brand’s material handlers. The certified high-voltage battery systems, which were specially developed for off-road applications and are already used in many e-mobility applications, are also used for the batteries themselves: 3000 full charge cycles guaranteed.

More convenience, reduced service requirements, maximum safety

The battery model also offers all the advantages of the tried-and-tested SENNEBOGEN electric material handler in terms of operator comfort and service – elevating Multicab comfort cab included. Thanks to this innovative battery-supported electric solution, all applications in the hall will be emission-free in the future and alleviate the burden on employees. At the same time, the machine operates with less vibration and noise, does not need to be refueled and has reduced service requirements, as there is no need to change the engine oil, etc. The operator can conveniently see the charge level indicator via the SENCON control system, does not have to carry out any separate settings even if the power supply is changed and therefore does not come into contact with the high-voltage technology used in normal operation. The dual power management system automatically detects the energy source and switches to the corresponding working mode automatically. In addition to regular diagnosis, the machine independently detects faults and interventions in the high-voltage system and then switches off in a controlled manner, which guarantees completely safe processes in every situation.