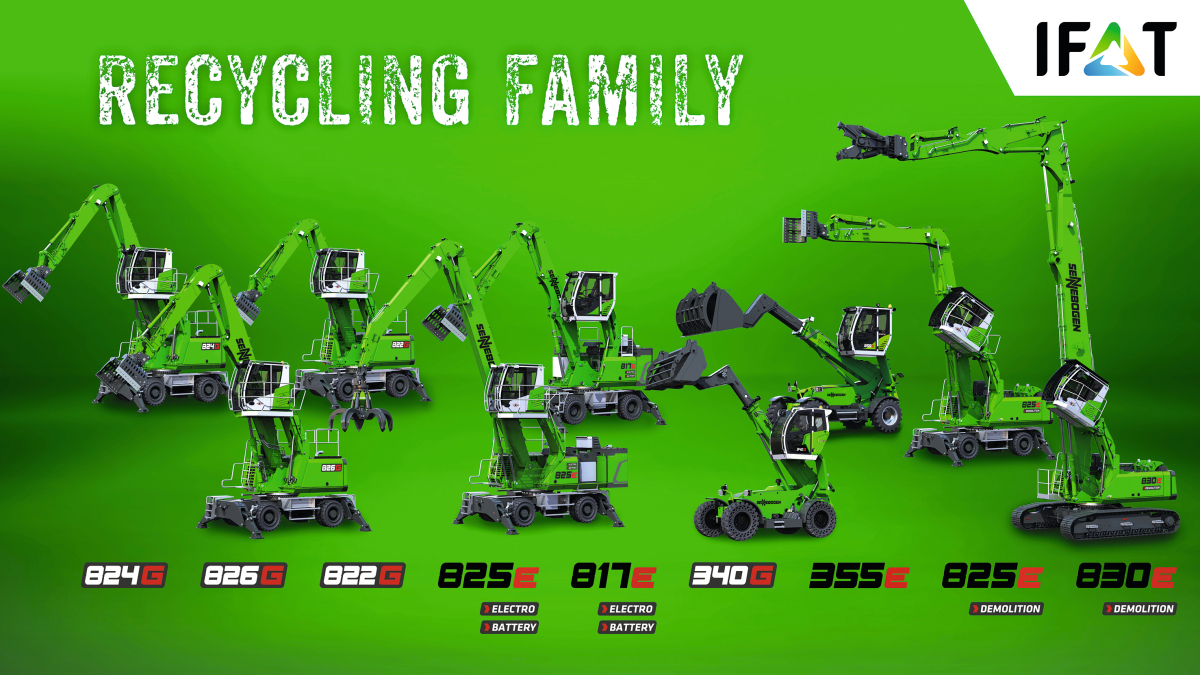

Focus on electric technology: Customized electrical solutions for more than 35 years

19.10.2023SENNEBOGEN presented a range of new machines at this year’s in-house exhibition, WE SHOW 71, which took place from September 19 to 22, 2023. As a technological milestone, alongside the new 6th machine generation, the G series, above all showcased the manufacturer’s extensive know-how in the field of electric machines. For decades, SENNEBOGEN has been offering all kinds of customer-specific solutions, from wired to battery, with many innovations to this day.

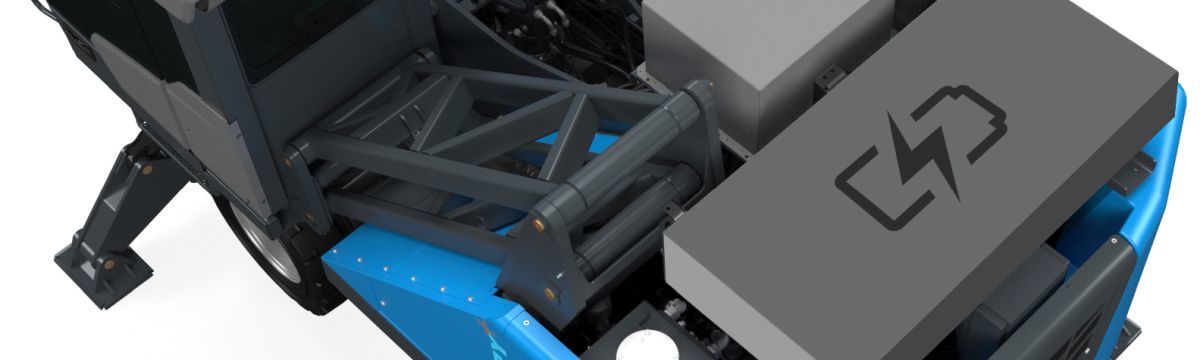

SENNEBOGEN battery technology with dual power management has proven itself in use for 1.5 years

SENNEBOGEN battery technology with dual power management has proven itself in use for 1.5 years

© Sennebogen

It has long been clear that electric solutions are on the rise in the mechanical engineering industry, because the current discussions about the consequences and causes of climate change is particularly centered around CO2 emissions, which are primarily caused by the combustion of fossil fuels. The technology drivers are not only the increasingly strict laws and requirements for large cities and conurbations, but also the market itself, which is making developments increasingly feasible due to the progressive maturity of technologies and the infrastructure required for them.

Energy savings of 30 % can be achieved with the Green Efficiency Drive electric travel drive

Energy savings of 30 % can be achieved with the Green Efficiency Drive electric travel drive

© Sennebogen

SENNEBOGEN recognized the potential of the electrification of machines early on and has been implementing customer-specific electric solutions for more than 35 years. The current state-of-the-art technology has already resulted in a wide variety of different electric drive systems. Technologically, there is no one-size-fits-all solution. Instead, each customer has their own specific requirements, which are considered from an economic and technical perspective, and for which the solution has to be found that is perfectly tailored to the application.

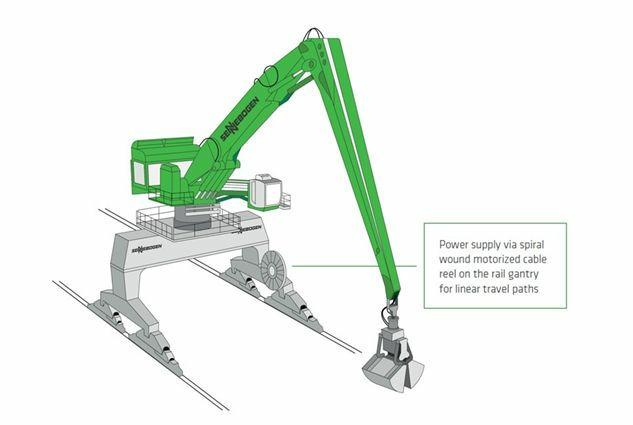

The flexible power supply via busbars enables individual mobility in a comfortable working area

The flexible power supply via busbars enables individual mobility in a comfortable working area

© Sennebogen

Stationary and cable-supplied electric machines

SENNEBOGEN offers a wide range of solutions for wired machine concepts alone: Stationary electric machines are ideally suited for applications where the working area of the machine is clearly defined and limited to a certain area. For greater mobility on straight-line routes, the power can also be supplied via the superstructure or undercarriage via trailing cables or motorized cable reels. A ceiling power supply is also suitable for machines that only work indoors.

© Sennebogen

© Sennebogen

If short distances have to be covered outside the working area, a combination with a diesel powerpack often proves to be the ideal concept. It can be used to effectively bridge short distances without power supply – for maintenance, for example.

Electric travel drive – Green Efficiency Drive

The hybrid solution of the electric travel drive, the Green Efficiency Drive, has proven itself for travel machines that frequently brake and accelerate again, such as the SENNEBOGEN 735 E Pick and Carry timber material handler. A generator installed on the diesel engine supplies the electric travel drive and additional braking energy is recovered during deceleration.

© Sennebogen

© Sennebogen

In addition to the electric drive, another advantage is that higher efficiency can be achieved via the more efficient electric motor and by relieving the load on the diesel engine, and energy consumption is reduced by up to 30 %.

Electric machines with battery technology

Since 2022, the electric portfolio has also been expanded to include freely movable battery models, which SENNEBOGEN has been operating under the name Electro Battery. The two 817 E and 825 E recycling material handlers – with an operating weight of 19 or 30 t – are currently available as battery-powered material handlers, and the 653 E telescopic crawler crane with 50 t and the 673 E with 70 t load capacity in the crane area. Its specialty? The Dual Power Management System allows you to work independently in battery operation as well as with a cable connection to the mains.

© Sennebogen

© Sennebogen

If the machine is connected to the power supply via the charging point on the undercarriage, stationary work can continue. A great highlight is that, when charging, excess power being fed in simultaneously recharges the batteries. SENNEBOGEN battery technology has been on the market for over 1.5 years and has proven itself with over 1000 operating hours in many applications.