Compact Performance in Chile

24.06.2025Since K 2022, EREMA has sold more than 20 INTAREMA® TVEplus® DuaFil® Compact systems. The first machines have been delivered and have entered operation. At RECUPAC S.A., for example, a recycling and waste disposal company based in Chile. "As the business unit for waste management at Coipsa, a group of packaging companies in Chile that are fully integrated in all phases of the circular economy, we process more than 150 000 tons of different materials every year," says Philippe Morizon, General Manager at RECUPAC.

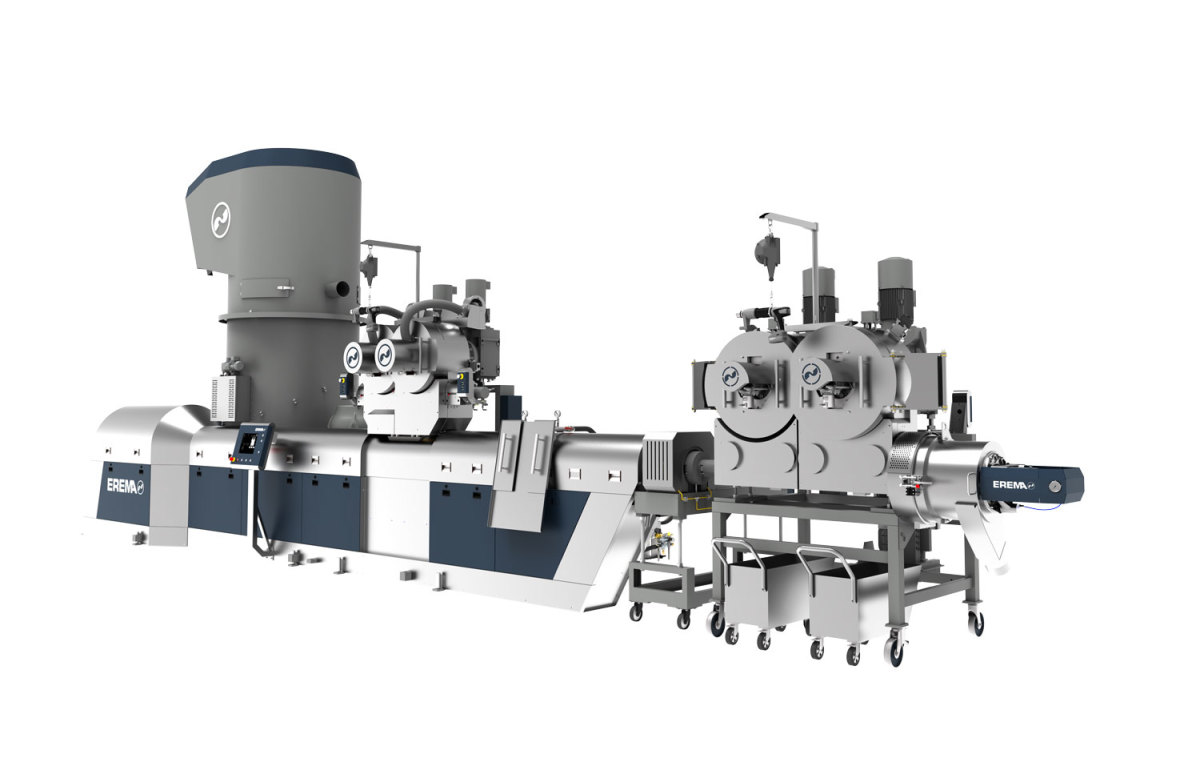

The Chilean customer RECUPAC uses the innovative and energy-efficient machine INTAREMA® 1512 TVEplus® DuaFil® Compact to produce high-quality recycled pellets suitable for making film

The Chilean customer RECUPAC uses the innovative and energy-efficient machine INTAREMA® 1512 TVEplus® DuaFil® Compact to produce high-quality recycled pellets suitable for making film

© EREMA

Low energy consumption meets high degree of automation

Plastics recycling is a relatively new field for the company. For their first machine, they decided on an INTAREMA® 1512 TVEplus® DuaFil® Compact. The objective is to produce high-quality recycled pellets suitable for making film. "Our customers have very high quality specifications, which is why we chose an EREMA machine," emphasizes Morizon. "With this compact recycling machine, we can produce high-quality pellets that are used to make film and can be used for other applications in the packaging sector. There were many arguments in favour of this machine, including its high overall efficiency. Particularly important factors were its low energy consumption and high degree of automation, which saves on operating personnel. I am confident we will meet our customers' expectations, and the initial results are very promising."

Lindner washing system

Philippe Morizon, General Manager RECUPAC, Chile

Philippe Morizon, General Manager RECUPAC, Chile

© EREMA

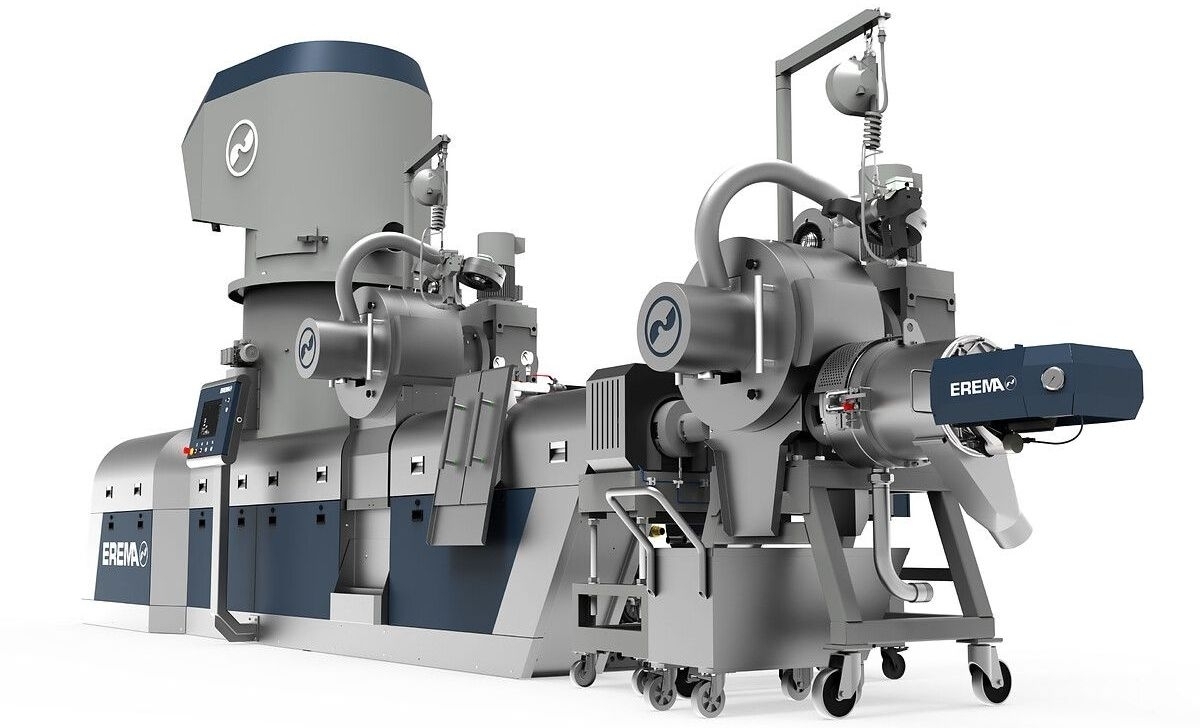

RECUPAC also operates a Lindner washing system. In August 2023, EREMA Group joined forces with the waste management specialist and founded a new holding company. The two companies want to work together to increase the energy efficiency of the overall process and further improve recyclate quality through technical cooperation.

Philippe Morizon, General Manager RECUPAC, Chile, said: “Our customers have very high quality requirements, which is why we have opted for an INTAREMA® 1512 TVEplus® DuaFil® Compact machine. There were many arguments in favour of this system, including its high overall efficiency. In particular, the low energy consumption and the high degree of automation, which saves on operating personnel, were important factors.”

The innovative INTAREMA® TVEplus® DuaFil® Compact significantly reduces the length of the extruder and thereby gets more out of it for quality-orientated recycling companies: Finest, double-filtered and optimally degassed regranulate quality – produced with high throughput and extremely low energy consumption.

At RECUPAC in Chile, a Lindner washing system works efficiently with an INTAREMA® 1512 TVEplus® DuaFil® Compact machine from EREMA

At RECUPAC in Chile, a Lindner washing system works efficiently with an INTAREMA® 1512 TVEplus® DuaFil® Compact machine from EREMA

© EREMA

The innovative INTAREMA® TVEplus® DuaFil® Compact significantly reduces the length of the extruder and thereby gets more out of it for quality-orientated recycling companies: Finest, double-filtered and optimally degassed regranulate quality – produced with high throughput and extremely low energy consumption.