When screen classifying cutters outperform hammer mills and knife cutters

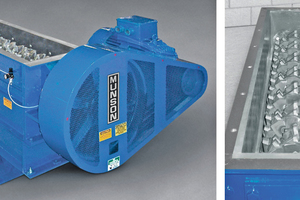

Screen classifying cutters combine the shear of a knife cutter with the impact of a hammer mill at high speeds, reducing friable, semi-friable, fibrous, semi-hard and hard materials into controlled particle sizes at high rates with minimal fines.

Like knife cutters they shear material against bed knives, but screen classifying cutters can handle a greater diversity of materials and retain sharpness far longer. At medium to high speeds, they additionally impact material similar to a hammer mill, but add the flexibility of variable RPM for greater control of particles sizes. As a result, screen classifying cutters are often more effective than either machine at reducing friable, hard and fibrous materials into uniform particle sizes from 15 cm down to 20 mesh (850 µm) or less, with fewer fines and/or less heat generation.

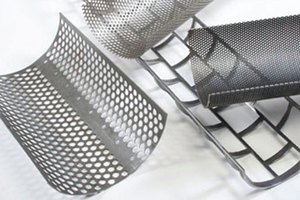

The infeed throat houses a horizontal rotor comprised of tightly-packed, staggered parallelograms or “stars,” each of which holds cutter tips that shear materials against twin stationary bed knives at lower rotor speeds, and additionally impart high impact at higher RPM. The rotor design generates many times greater force per inch with each cut than a conventional knife-type cutter of equivalent horsepower.

As material enters the infeed chute, it is subjected to successive mechanical shearing against the bed knives until small enough to pass through the screen apertures, the size of which determines residence time. The result is uniform, coarse grinding down to 20 mesh (850 µm) with minimal fines or heat generation, and reduced energy use.

Typical applications include reducing bulk foods, spices, sugar cane and hemp stalks, tobacco, plastics, batteries, brake pads and compounds, chemicals, clays, coal, minerals, detergent blocks, fiberglass insulation, filter cake, gypsum, ceramic honeycomb filter media, carbon/aramid fiber, leather, glass bottles, trim stock, wood products and a broad range of scrap.

The rotor of a screen classifying cutter can range in length from 25 to 183 cm, and its geometry can be adapted to optimize the application. Standard models have a 28 cm wide infeed throat that houses a 26.7 cm diameter horizontal rotor comprised of tightly-packed, staggered parallelograms, each of which holds two 1.3 cm wide cutter tips. An ultra-heavy duty Magnum™ version with 57 cm wide infeed throat has a 46 cm diameter rotor comprised of 4-sided “stars,” each of which holds four 1.3 cm wide cutter tips, boosting capacity by approximately 75 % and accommodating larger infeed sizes.

Available in food-grade, industrial and abrasion-resistant finishes, and in a range of sizes from mini laboratory units to ultra-large units six feet (1.8 m) in length, screen classifying cutters can mince, crush or crumble materials that are soft, moist, sticky, medium-hard, fibrous, or friable offering great flexibility in size reduction.

Following are several case history examples that examine the performance of screen classifying cutters in reducing a diverse range of materials.

Thermoformer recycles plastic scrap,

reduces maintenance

A major plastics thermoformer, whose operations include sheet extrusion and calendering, installed 20 screen classifying cutters to assure efficient granulation and sizing of its process scrap. The company runs the cutters at full capacity during production runs to deliver properly-sized granulate for processing. The screen classifying cutters replace units that required frequent blade changes and could not keep pace with the high production rates.

The cutters have a 38 cm wide infeed throat and 1.3 cm cutting blades with carbide tips. The blades are designed to slide onto each machined holder and be screwed into place. Changeover requires minimal downtime. Scrap from the extruders and a calendering line ranges in thickness from 8 to 40 mils. The scrap is pneumatically fed to the cutters in a continuous operation that runs 24/7. Each cutter processes at a rate of 113 kg/h.

The screen classifying cutters enable the plant to reduce the size of process scrap in the required capacity, with the uniformity needed to reprocess the material efficiently, improving efficiency of the operation.

Producer of calcium chloride satisfies

high demand

Cal-Chlor of Opelousas, Louisiana, operates five 76 cm screen classifying cutters to meet demand for calcium chloride powder used by the petroleum industry. The plant reduces CaCl2 pellets into a powder comprised of uniformly sized particles that is used in drilling shale formations, flushing mud from oilfield holes, and filling casings when drilling ends.

Each screen classifying cutter processes up to 11 793 kg of product per hour, says Brett Davis, operations director. The cutters are so important to meeting oilfield on-time demand that Cal-Chlor runs four of them and keeps the fifth for emergency use if one goes offline. The plant‘s daily CaCl2 powder production ranges from 181 to 363 t.

According to Davis, the cutters are „near bulletproof“ when it comes to processing CaCl2, which is abrasive, generates heat when collected in large volumes, attracts moisture, and is extremely difficult to handle. He notes that as little as 84 to 112 gm of CaCl2 in a cup with water will become too hot to hold in minutes.

Each cutter at the Opelousas plant has a 76 cm long by 28 cm wide infeed chute. The cutters are made of stainless steel, which resists abrasion, corrosion and other problems that CaCl2 presents. Cal-Chlor operates the machines at between 1200 to 1800 RPM to achieve the desired particle size.

Mini paper mill increases efficiency, lowers energy requirement

The University of Maine Process Development Center (PDC) provides the paper industry with leading-edge, collaborative pulp and paper research. The process lab – originally part of the university‘s forest and paper industry program – houses a virtual „mini“ paper mill with a broad range of processing equipment.

The PDC is equipped to work with a range of raw materials including wood, bark, herbaceous crops, and agricultural residuals. Available processes include extraction, pulping, bleaching, papermaking, coating, and finishing. To facilitate its process work, the lab requires efficient size reduction capabilities to downsize materials into uniform particles.

At the outset, the lab used a hammer mill which proved to be inefficient and failed to produce consistently sized particles due to its crushing and pulverizing action. The PDC replaced it with a screen classifying cutter. „We specified that unit because it efficiently reduces materials into uniform particle size with a lower energy requirement than the Hammer Mill,“ said Mark Paradis, the PDC‘s group leader of engineering. He added that it requires minimal maintenance.

The screen classifying cutter played a key role in one initiative to reduce perennial grasses and hay into 3.2 mm particles which were then compressed into biofuel pellets. In another project, a University of Maine chemical engineering professor developed a biodegradable golf ball partially composed of lobster shells. Here, the screen classifying cutter reduced the shells to powder form for downstream processing.

Ordnance fabricator saves money, recycles tungsten heavy alloys

Aerojet Ordnance of Jonesborough, Tennessee, fabricates parts from tungsten heavy alloys and other refractory metals for defence-related products like ammunition, warheads and electronic shielding. Tungsten heavy alloys are one of the densest metals produced. Reclaiming fabrication scrap was difficult and costly, prompting Aerojet to sell the scrap at significantly lower prices than it was worth as a recycled and reusable material.

Looking for a better solution, Aerojet experimented with techniques to reclaim tungsten heavy alloys scrap, including using a Hammer Mill and manually downsizing pieces. None of the methods was efficient or produced consistently sized particles. According to Tim Brent, project engineer, a Hammer Mill‘s crushing, pulverizing action was not effective with material of this density and generated dust. With manual reclaim, „labour costs were prohibitive and the results uneven.“ Brent continues: „If we can reuse the material, it is worth two- to three-times more to us than selling it as scrap. But we couldn‘t reuse the material without an effective means of size reduction.“

After testing several size-reduction machines, comparing particle sizes, consistency and economy, Aerojet decided on a screen classifying cutter with a 38 cm long rotor. Aerojet‘s engineers were aware that the machine had a successful record in similar applications. „The design is simple and stands up to the tungsten heavy alloys,“ says Brent.

Aerojet specified an abrasion-resistant interior and a special stand to accommodate containers used in moving scrap to the process machines. „Downsizing different grades of tungsten heavy alloys raises the risk of batch contamination if the interior isn‘t properly cleaned,“ he notes. „The cutter is easy to clean, compared to other machines,“ he says.

Conclusion

Hammer mills and knife cutters are often default choices for size reduction due to their longterm existence, familiar names and broad capabilities. However, the range of applications they can satisfy efficiently is narrow. Indeed, many hammer mill users sacrifice particle size control and excessive fines, while many knife cutter users are resigned to frequent shutdowns for re-sharpening of blades that quickly lose their edge. In these and other situations, plant engineers would do well to test their material on a screen classifying cutter side-by-side with a hammer mill and/or knife cutter in manufacturers’ test labs. Only in this way can he or she quantify the difference in efficiency, output and product quality afforded by each machine, and reap performance benefits over the long service life of the ultimate purchase.