Sutco® ProDigit - smart data for smart decisions

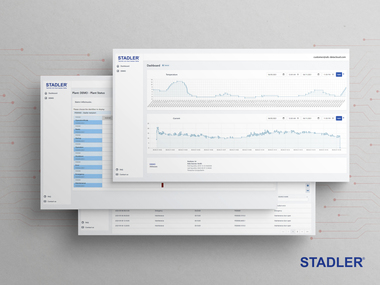

Sutco RecyclingTechnik GmbH has created a digital platform that raises efficiency, transparency and productivity to a new level through the seamless recording, analysis and visualisation of operational data.

With ProDigit, we are continuing to drive digitalisation in the recycling industry. The platform offers our customers an intuitive, powerful solution for monitoring, analysing and optimizing sorting processes and plant operation in real time, explains Yannick Rödder, Head of Process Engineering at Sutco.

Digital control for maximum efficiency

The web-based all-in-one platform is accessible on both desktop and mobile devices without installation. The modular system also enables flexible expansion with additional functions and upgrades that support the entire life cycle of the system.

Customizable user experience

and plant management

ProDigit offers personalised user accounts with detailed permission management so that companies can determine exactly which employees have access to certain information or are allowed to make changes.

Customers can manage and customize the information that ProDigit utilizes to make their plant operation easier: A particular highlight is the automated shift model, which enables precise recording and analysis of shift-related data. The resulting shift reports can be summarized in daily, weekly and monthly evaluations and provide valuable insights into production performance.

Optimised production processes through smart analyses

With ProDigit, operators can keep an eye on the entire sorting process at all times:

Timeline visualization for real-time monitoring of production processes and throughput quantities

Automatic recording of downtimes including root cause analysis and comment function for operators

Tamper-proof shift logs for complete documentation. The platform also enables detailed fault analysis: machine-related downtime analyses, intelligent fault source rankings and heat maps help to identify optimisation potential at an early stage and initiate targeted measures.

Efficient reporting and data export

Automatic reporting – Important key users receive daily, weekly or monthly reports by e-mail.

Production and performance KPIs can be calculated and compared for any period of time.

Seamless system integration – ProDigit enables easy data export to existing IT structures via Excel export or REST API

With ProDigit, Sutco is setting new standards in digital process control. The platform combines maximum efficiency, safety and flexibility to optimise tomorrow’s sorting technology today.

Future-proof and worry-free

The waste industry is driven by constant innovation, and ProDigit is evolving in the same way. Over-the-air updates continually increase functionality and ensure that plant operation stays up-to-date. Updates are free for all ProDigit customers.

There is no need to worry about system maintenance, data backups, or security patches. ProDigit comes as a full-service package, taking care of the infrastructure behind the software so that customers can focus on the things that actually matter.

“Digital transformation is essential for economical and sustainable waste management,” emphasizes Naemi Denz, Managing Director of Sutco. With ProDigit, we are creating a solution that truly helps our customers to make their operating processes smarter, more efficient and more transparent.