Optimizing processes with mobile weighing systems

In 1979, Hans-Günther Pfreundt established a company for manufacturing mobile weighing systems, and from 1983 the first mobile calibrated weighing system was launched onto the market. Hans- Günther Pfreundt was convinced that the idea and the need to equip mobile working machines with calibrated scales was the obvious way forward at that time – and as he put it: “The market was ready for it!”.

Since then PFREUNDT GmbH has been designing, developing and selling mobile weighing systems as well as the software and data transfer systems for international markets in the extraction, waste management and recycling industries. While the company started out with a handful of employees in the cellar of Hans-Günther Pfreundt’s home, it has enjoyed steady growth. PFREUNDT GmbH currently employs 94 people and has already supplied more than 40 000 weighing systems worldwide.

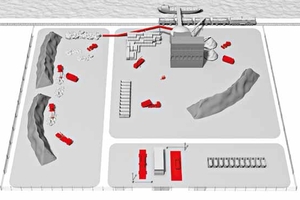

The integrated weighing systems are used in a wide range of applications, like, for example, in roll-off tippers or skip loaders, excavators, crushers, belt conveyors, cranes, wheel or front-end loaders, telescopic handlers, and stackers to determine load weight direct in the workflow. In addition, PFREUNDT GmbH offers an extensive product portfolio for stationary weighing, e.g. weighbridges, axle load scales, platform scales or industry and laboratory scales.

A key goal of the company from the start was to supply products of high quality. These are adapted in ongoing further development to the needs of the market, relevant legislation thanks to their calibration, as well as the needs of the customers. Up to now, activities have been concentrated on the extraction sector. The recycling industry, however, presents a promising market, on which the company plans to focus more strongly in future. Precise weighing of the material streams is playing an increasingly important role in this sector as actual value creation is achieved by reselling cleanly separated, recycled materials. Billing is based on weight.

IMR Innovative Metal Recycling GmbH, headquartered in Krefeld with a branch in Siegen, has been a customer of PFREUNDT GmbH since back in 2009. Over the years, IMR has acquired a total of six excavator scales and four wheel-loader scales, which are distributed over its two sites. The metal recycling company works in processing different secondary resources to separate grades and trades these. The recyclates are supplied, for example, to smelting operations, for use in the production of high-quality stainless steel. Another Rohstoffaufof IMR’s lines of business is processing and trading non-ferrous metals.

Overall, IMR processes collected scrap alloys, NF metals, Fe scrap or composites to recycle these effectively and reintroduce them into the economic cycle, combatting the dwindling supply of primary raw materials. As soon as the separated and recycled material streams, such as aluminum, copper, brass, zinc scrap, etc. for are ready for loading onto lorries or rail wagons, accurate determination of their weight with the help of PFREUNDT GmbH’s mobile weighing systems is essential.

How far mobile weighing systems from PFREUNDT GmbH can make workflows and processes more efficient was the subject of a talk held by Ulrike Mehl, editor of recovery – Recycling Technology Worldwide with Katja Mattejat from the marketing department and Michael Buning, sales executive at PFREUNDT GmbH:

recovery: What opportunities do you see for your company in the recycling sector?

Katja Mattejat: In the recycling and waste management industry, many companies are still working exclusively with stationary weighing installations. For that reason, with our mobile weighing systems we have the opportunity to contribute to improving efficiency. On the one hand, it’s about the precise calculation of costs. If I know how much weight has been loaded, I can bill this correctly and avoid losses. On the other hand, workflows can be optimized and costs saved as a result.

recovery: What advantages do mobile weighing systems have compared to stationary weighing?

Michael Buning: Unlike stationary weighing systems, with mobile scales, the transport weight is determined directly in the loading machines, e.g. wheel loaders, stackers or excavators, during loading. This avoids overloading and unnecessary trips to the stationary weighing installation. With our mobile weighing systems, the transport capacities can be optimally utilized directly during loading. A lorry with its load don't has to drive over a stationary weighbridge when leaving the site for a final check, the driver receives the relevant papers, and can then go on his way. Let me explain this more clearly with an example: If a company is working only with stationary weighing systems, a first and then a second weighing are prescribed. That is first the empty lorry drives over the weighbridge to determine its unlade weight. Then the lorry is loaded the material to be transported and the lorry drives over the weighbridge for the second weighing. If not enough or too much material has been loaded, the lorry has to be loaded with more material or material has to be unloaded. In the worst case, the lorry has to drive over the weighbridge several times until the target weight is reached. This can lead to a considerable time loss in the workflow.

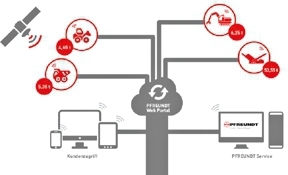

Katja Mattejat: The range of mobile weighing systems is not just limited to loading, but can be used directly during transport. As a result, transport weights, transport times, distances, loading and waiting times can be recorded and evaluated. This allows us to identify potential for optimization in the workflow and advise our customers accordingly. For this purpose, over the last few years, we have developed dedicated software solutions that enable our customers to access the weighing data and thereby facilitate evaluation of the data. Since 2015 we have offered the PFREUNDT Web Portal, which enables automatic data exchange with the mobile weighing systems. The users have access to the data practically anytime and anywhere – whether they’re in the office, at their PC or on the move via smartphone and tablet. The Web Portal also makes available individual evaluation functions and interfaces for further processing in the customer’s own systems. Without the installation of additional software, our customers can use their web browser to access all the functions of the PFREUNDT Web Portal.

recovery: How does direct mobile weighing work?

Michael Buning: I’ll explain that best with reference to our WK60, which we introduced in 2015 as the first mobile scale with touch display and connection to the PFREUNDT Web Portal. The WK60 is our flagship, it has a wide range of interfaces for printer, network, CAN bus, a large memory for the master data and user administration, a calibration data memory for additional attachments, data transfer by WLAN and much more. The operation of this mobile weighing system is very simple, comparable with the user interface of a smartphone or a tablet. As soon as the driver switches on the device installed in the cabin, the various functions can be identified by corresponding symbols and it is intuitively clear what you have to do. The driver enters the weight to be loaded directly via a target weight function, e.g. 20 t metal scrap. The gripper arm of the telescopic handler, on which sensors determine the weight of every single load, grabs the scrap and loads the lorry until the target weight has been reached.

recovery: Then the standardized precision of your weighing systems is an important factor for the entire workflow. Who is responsible for the initial calibration of your weighing systems?

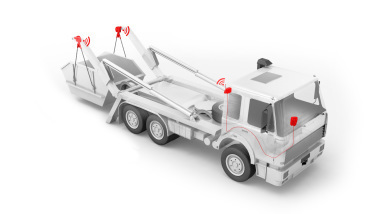

Michael Buning: On account of the statutory regulations for goods handling, the weighing systems used here must be calibrated. PFREUNDT GmbH has all the necessary approvals, both national and international, to sell calibrated weighing systems on the market. To this end, we have our own metrology department. The metrology department manages measurement standards and ensures the worldwide acceptance and comparability of measurements so that the accuracy of the measurement results are universally recognized. With metrology, we ensure that our calibrated scales deliver precise results with verifiable validity. On delivery, our service technicians not only install the weighing system in the vehicles – independent on the vehicle type. They come with one of our total of six PFREUNDT calibration lorries fully equipped with 15 t calibrating weights and hoisting crane, to perform the conformity assessment. We offer this service to our customers all over Germany.

recovery: Do the weighing systems have to be adjusted at certain time intervals?

Katja Mattejat: The weighing systems have to be recalibrated every two or every three years, and that in the presence of the responsible weights and meas- ures office and our service technicians, who perform the checking and any necessary readjustment of the scale. We do this as part of our customer service.

recovery: Is the calibratability of industrial weighing systems a topic internationally?

Katja Mattejat: On the international market, the calibratability of weighing systems isn’t always so important. For this reason, we are now launching a product on the market, which cannot be calibrated. The newly developed WK60-XS is a lower cost variant of the WK60. The WK60-XS with an intuitive 5" touch display is a basic model for all standard requirements, independent of the vehicle manufacturers. In addition, a large selection of different features is available for specific workflows, which we can adapt depending on customer requirements, such as larger weighing data memory. It is small and compact like a smartphone and ideally suitable for internal processes, like control weighing. The WK60-XS is already available for wheel loaders, telescopic handlers and forklifts because work with these is based on the same measurement principle. The software for this model is, however, currently being further developed so that it can be used for all applications common on the market.

Michael Buning: We not only maintain a partnership- based exchange with our customers to find the best solutions for practical application. We also engage in active dialogue with the major machine manufacturers in the sector to ensure our weighing systems remain compatible with the latest series of machines.

recovery: That was an interesting insight into industrial weighing electronics. Many thanks for talking to us.