NexKemia Expands EPS Production Capabilities with ZSK Twin Screw Extruders to Incorporate Recyclates

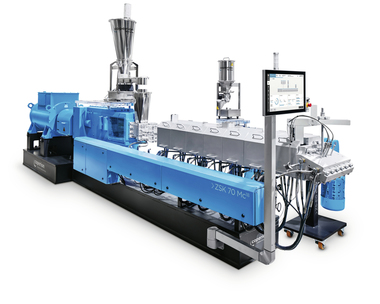

NexKemia Petrochemicals Inc., a leading firm in manufacturing expandable polystyrene (EPS), has relied on ZSK twin screw extruders from Coperion since 2020. Focusing on innovative manufacturing processes and sustainability, NexKemia provides products for the packaging industry and as well as for building insulation. Along with white EPS, NexKemia also produces EPS mixed with graphite, known as GPS (polystyrene mixed with graphite-enhanced polystyrene), as well as products containing up to 30 % recyclate.

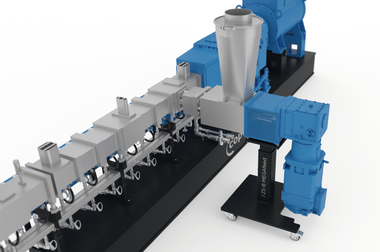

For manufacturing and product development, NexKemia uses Coperion ZSK twin screw extruders, which enable an environmentally friendly production and gentle product handling of white and gray EPS as well as the integration of recycled materials on a single production line.

Twin screw technology simplifies production process

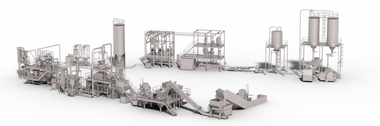

Conventionally, white expandable polystyrene (EPS) is manufactured discontinuously within the scope of suspension polymerization, whereby the monomer styrene is polymerized in a batch process. Alternatively, continuous manufacturing processes exist whereby processing occurs with the feeding of additives and pentane in several successive process steps. Various combinations of twin screw extruders, single screw extruders or static cooling mixers are used. Coperion, in contrast, offers a technology for manufacturing EPS in a very simple, single-step process, using the ZSK twin screw extruder.

Particularly in the case of suspension polymerization, the chemical balance during the reaction must be maintained, as even minimal impurities or foreign materials can disrupt the balance and destabilize the process. As no reaction takes place in the extruder, but rather the substances are mixed, this does not pose a challenge to this manufacturing process. All ingredients are fed into the Coperion ZSK extruder via high-accuracy Coperion K-Tron feeders and processed into a homogeneous mass using precisely modified shear introduction and short residence time. This ensures a low thermal stress upon the material. Micropellet manufacturing takes place in an underwater pelletizer following the extruder, generating very small pellets (≤ 1 mm) with a very narrow particle size distribution.

Economical and sustainable manufacturing of innovative EPS products

Along with the novelty of single-step EPS manufacturing, the ZSK extruder also enables production of graphite-enhanced polystyrene (GPS) as well as products containing recycled material. When manufacturing GPS, free graphite, among other ingredients, is added to the product which reflects the heat radiation and thus offers higher heat insulation than white EPS. NexKemia‘s GPS products demonstrate a very low lambda value, representing a lower heat conductivity and thus very good insulating capacity.

NexKemia has succeeded, together with Coperion, in integrating recycled material into EPS manufacturing — on just one production line. The purified and compacted regrind can be fed directly into the ZSK extruder. Depending upon quality requirements, micropellets, and availability of the discharge material, recycling content of up to 30% or greater can be realized. The final EPS product is outstanding, with equal physical properties to those of new products. Moreover, the process is superior to others with markedly lower airborne emissions, as well as a significant reduction in wastewater production.

“Using Coperion twin screw extruders, we have the ability to manufacture specialized products for various applications. Thanks to the excellent collaboration and process-technical support, we were able to realize new and environmentally friendly processes together for EPS manufacturing. This allows us to be true to our values of customer focus, innovation and sustainability”, said Michael Hays, President of Integreon, parent company of NexKemia.