New Dimensions of Wear Protection

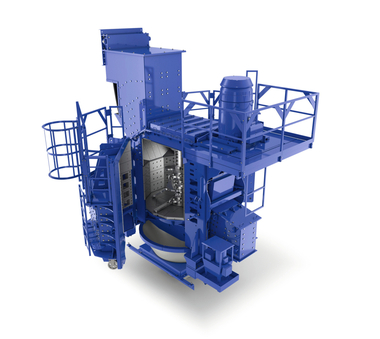

Understanding, developing, producing and advising: With this four core competences SWB counters wear in the field of shredder technology and presents them as new dimensions of wear protection at IFAT. At the same time, the focus is on a common conservation of resources together with SWB’s customers.

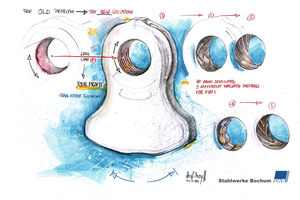

SWB is permanently researching pioneering solutions against wear. Newest developments are a by now internationally patented striking tool with a structured inner circumferential surface of the bearing opening as well as patent pending striking tools with an enhanced bearing opening. These complement product optimisations made the in the recent past: wear optimised shredder hammers referred to as ‘The Original with a New Formula’ with an improved stress resistance and a reduced risk of chipping and the trusted ‘Winter Hammer’ with its highest possible operational reliability under harsh winter conditions.

Currently 37 different types of alloy steel ensure an optimal fit of the wear parts for their respective range of application. A complete surveillance of the entire production process and extensive quality controls guarantee the consistently high quality of the SWB products.

The SWB team advises customers on site in more than 50 countries worldwide and offers individual support for customer specific challenges. Wear parts specifically produced for their dedicated application area improve plant efficiency.

SWB opts for a sustainably CO2 reduced production, operates a DIN EN ISO 50001 : 2018 certified energy management systems and has always offered its customers the chance to return worn impact tools and linings against reasonable remuneration. With its products made out of steel scrap SWB is essentially involved in the steel recycling process of its customers. Together with its customers SWB therefore operates sustainable environmental protection and saves resources, since with the recycling of 1 t steel scrap – against the use of primary raw materials – at least 1.67 t CO2 are prevented.

stahlwerke-bochum.com

Hall B4, stand 429