New building creates space for project planning

and development

Hellweg Maschinenbau, a global manufacturer of digitally controlled shredding machines for effective, energy-saving plastics recycling, is well prepared for the market recovery in the industry. Although the current dark clouds over the recycling world mean that the sales records of the two previous years cannot be expected in 2025, Managing Director Mark Hellweg sees exciting ideas and the exceptionally high profitability of his granulator portfolio as proven pillars that will continue to support success as soon as the economy brightens up.

In order to create optimal conditions for this, the company recently moved into its new administration building at its headquarters in Roetgen. A total of 300 m² of floor space now offers a comfortable environment for the development and implementation of new projects.

“We have consistently digitalized our systems for shredding plastics and trimmed them to unprecedentedly low energy consumption,” says Hellweg. “We were able to reap the rewards of this development work in the two previous years. The high level of efficiency combined with the long service life of all installed components has convinced more and more users, and with this combination we want to secure a prominent position in the industry in the future.”

In order to be able to follow this path, the company has not only expanded its premises but also increased its staff. For example, Dirk Nebel joined the team as a project engineer a few weeks ago. Hellweg has also switched its product development to one of the most powerful CAD programs currently available and is planning to introduce a new ERP system this year. “We are continuing to focus on innovation and, above all, on digitalization, both of the company and of our products,” adds Hellweg. “We also want to open up new markets. To this end, we will demonstrate the particularly energy-efficient and low-dust operation of our shredding systems in other areas in addition to pure plastics applications.”

Grinders for every plastics application

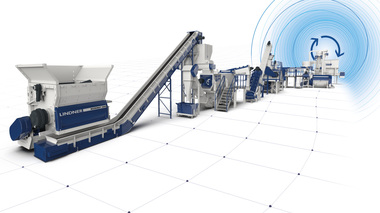

Hellweg‘s product portfolio includes robust, durable granulators for every plastics application – from small beside-the-press granulators for grinding sprues to high-performance systems for solid parts, films and sheets, with a throughput of 5 t/h and more. They are all equipped with the digital Smart Control system developed by Hellweg. This records parameters such as power consumption, motor speed and bearing temperatures as well as the condition of knives, screens and V-belts. It is also able to continuously optimize the ratio between motor load and throughput. The result is particularly economical operation with minimal effort for the operating personnel. The special cutting geometry of Hellweg mills enables low-dust regrind with consistently high quality and perfect particle size distribution and geometry for further processing. This range is complemented by edge trim shredders and servomotor-driven edge trimming systems for film or sheet production.