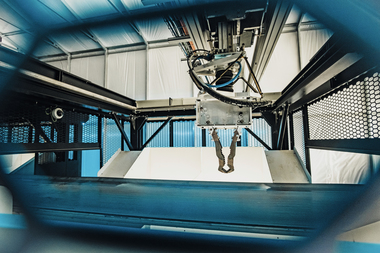

Max-AI® AQC-2 available for paper sorting

The Max-AI® AQC (Autonomous Quality Control) product line has expanded with the release of the AQC-2 for paper sorting applications.

The new capabilities coincide with the industry’s demand for technology to create a clean news product. The AQC-2 sorts at speeds superior to manual sorting while recovering cardboard, containers and plastic film and removing contamination to create a clean news product. The AQC-2 complements BHS’ Tri-Disc technology and NRT optical sorters to fully automate the quality control process for paper and containers. The level of automation possible with Max-AI technology will significantly lower operating costs – especially while running multiple shifts – while adding production and quality capabilities that surpass those of manual sorting.

“The Max-AI AQC-2 fills a sizeable hole in the marketplace,” said BHS CEO Steve Miller. “The NRT ColorPlus™ does an exceptional job of recovering most of the cardboard that, due to the increase of online shopping, has infiltrated the news stream. While it doesn’t make financial sense to add another optical sorter to remove the remaining small cardboard, it does make sense to add the AQC-2, equipment that will recover the remaining cardboard while at the same time removing other commodities or contaminants from the news stream. The results have been excellent and the investment really pencils out. We are thrilled to have a solution for our customers that creates clean news with zero labor and provides a fast return on their investment.”

//www.bulkhandlingsystems.com" target="_blank" >www.bulkhandlingsystems.com:www.bulkhandlingsystems.com