Gneuss at K 2019

Gneuss Filtration Technology showed several different models of their patented Rotary Filtration Systems.

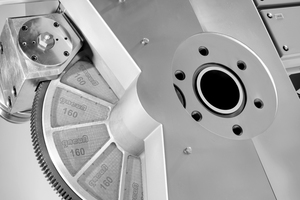

These continuous filtration systems are characterized by a filter disk on which the screen cavities are located in a ring pattern. Screens can be changed on the part of the filter disk that is not active in the melt channel, while the production process continues to run without any interruptions or disturbances.

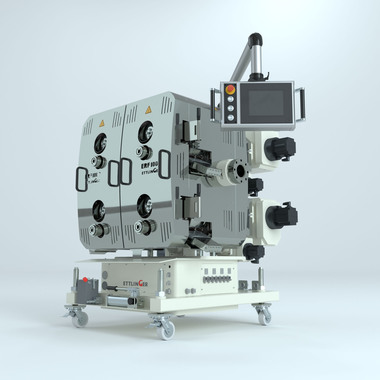

The new model SFneos was developed to combine the charactertistics of several older models into one simple and cost-efficient solution, offering the following advantages:

Constant pressure guaranteed – even during screen changes

Suitable for most types of polymers and viscosities

Compact design thanks to an enlarged active screen area (up to 2370 cm2)

Simple and safe handling and operation with several screens accessible for screen changes

Very cost effective thanks to its improved design

The SFneos is the ideal filtration system for applications that benefit from a continuous, pressure and process constant screen changer, but that don’t require back-flushing. The SFneos 90 exhibited at K-show has an active screen area of 260 cm2 .

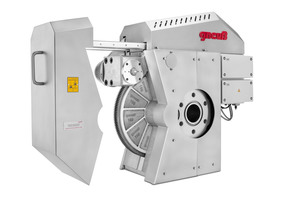

Gneuss’ top model, the RSFgenius, operates with an integrated self cleaning system for very demanding applications and highest quality requirements. Screens can be automatically re-used up to 400 times and filtration finenesses below 10 microns/1200 mesh are available. There were different sizes on display, including an RSFgenius 330, which was the biggest filter on the Gneuss booth. It offers an active filtration area of 2150 cm2 and was shipped to an end customer in Southern Europe after the show.

Last but by no means least, Gneuss exhibited two KF screen changers, a KF 75 with an active screen area of

44 cm2 and a KF 110 with an active screen area of

95 cm2 .

The KF 110 was installed in a blown film line at Brazilian machinery manufacturer Carnevalli’s booth. The KF series of continuous filtration systems is designed specifically for applications with frequent material type, grade or color changes as well as for high pressure applications like blown film.

Gneuss also offers a new semi-continuous model, the CSFprimus. This model is used as a pre-filter, safety filter or in applications with little contamination and is characterized by a very large active screen area for its small footprint.