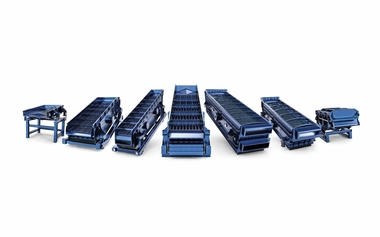

Efficient processing with SPALECK

SPALECK is one of the leading international quality manufacturers of conveying and separation technology. At RECYCLING-TECHNIK Dortmund, the screening machine experts will present their latest developments for the precise screening and processing of recyclables of all kinds.

NEW: SPALECK ActiveFEED feed hopper – profit maker for sorting

For operators of recycling plants, economic efficiency, sorting quality and the successful interaction of all machines in the overall plant are crucial. For this very purpose, SPALECK has completely rethought the material feed of recycling lines and, with the ActiveFEED feed hopper, has for the first time created an optimal and controllable material feed of the downstream aggregates. For this purpose, the ActiveFEED feed hopper independently monitors the specified discharge rate and automatically adjusts its oscillation parameters so that the optimum amount of material always runs over the downstream aggregates.

SPALECK TestCenter guarantees screening technology of the latest generation

The processing is then continued with the latest screening technology with very high separation accuracy. Here, the machine manufacturer from NRW offers its customers state-of-the-art waste screens, flip-flow screens as well as 3D-COMBI screening machines. The special feature: Thanks to the 1500 m² TestCenter, where hundreds of screening tests are carried out for customer projects every year, the screening technology is always at the cutting edge. Frederik Stening, head of application technology at SPALECK: „It is important for us that our customers can flexibly adapt their SPALECK screening machine to the screening material. Because this is the only way to guarantee that they can reliably supply the screen qualities required by the market.“

SPALECK ComfortLINE for pharmaceuticals, chemicals & foodstuffs

In addition to machines for recycling materials, the company‘s SPALECK ComfortLINE product line offers customized solutions for the pharmaceutical, chemical, plastics and food industries. Key advantages of the SPALECK ComfortLINE screening machines and vibratory feeders: they meet the highest hygiene and cleanliness standards, offer optimum cleaning options and impress with their high performance in screening, conveying and dosing. You can find out about all SPALECK trade fair innovations directly at RECYCLING-TECHNIK Dortmund, which is being held together with the SOLIDS bulk materials trade fair in the Westfalenhallen, at booth T29-7 or in advance online at www.spaleck.de.