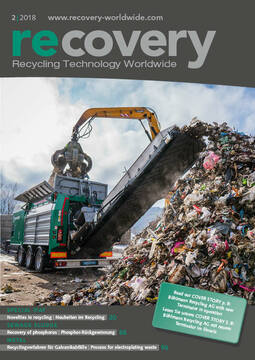

Bühlmann Recycling AG with new Terminator in operation

„He has often been the one who initiated the ideas of everything that can be done using machines“, summed up Peter Grepper of Getag Entsorgungs-Technik AG on his long-enduring cooperation with Hansueli Bühlmann. The foundation stone for the present-day Bühlmann Recycling AG was the parental farmstead, where scrap iron and other metal was collected, sorted and resold, primarily in the winter months. In 1981, Hansueli Bühlmann took over his father‘s business in Münchenwiler, around 30 km from Bern.

Nowadays, all types of waste are collected and processed at Bühlmann Recycling AG. And processing means, for Hansueli Bühlmann, breaking down and sorting the waste with such quality that new feed materials which can be directly reused in other industries, as their feed materials, are produced without any roundabout process routes. Waste, provided it is processed in sufficient depth, also gains significantly again in value. New routes must be explored for this purpose, and machines tested for the various fields of application. This is Hansueli Bühlmann.

Bühlmann Recycling AG now has a total of 6 locations: Münchenwiler, Cressier, Lyss, Heimberg, Spiez and Interlaken. This firm, one of the major companies in Switzerland in the field of scrap processing and the recovery of noble metals, now employs some 170 persons. The equipment necessary for each application has been purchased and installed piece by piece, to tackle new comminution and sorting tasks as they arose. All in all, the fleet of machines now includes high-capacity shredders with built-in eddy-current separation (Hofmann Group, Venti Oelde), a Lindner Universo granulator mill, Steinert KSS and Unisort Black sorting systems, a Europress channel baling press for cardboard and paper, three Komptech Terminator 3400S machines for pre-shredding of cables, plastics, rubber and oversize items, and two Komptech Crambo machines for processing of wood for production of chipboard. The present-day owners of this family company are Hansueli Bühlmann and his brother-in-law Martin Ritschard, who both make up the supervisory board and are also, simultaneously, active operational managers.

Terminator

Low-speed single-shaft shredder

Available in three sizes

Mobile and stationary models available

Suitable for shredding of oversize waste, used wood, mixed building waste, domestic waste, residual waste, commercial waste and special applications

Three different drum types (universal U, fine F and extra-fine XXF) for various degrees of fineness

Reversing always cures jams

Hydraulically adjustable cutting gap

Drum length: 3000 mm; drum diameter: 1050 mm

Throughputs of max. 45 to max. 100 t/h, depending on model

Crambo

Universal shredder for green waste and wood, six different models

Aggressive intake thanks to long, contra-rotating shredder drums

Variable particle-size range, thanks to simple screen basket changing

Swing-out screen basket cartridge

Hydraulically pivoting over-belt magnet

Drum length: 2820 mm; drum diameter: 610 mm

Throughput from max. 55 to max. 100 t/h, depending on model

At the IFAT

Komptech will present several new and updated machine models in Hall B6, booth no. 405/504, at the open air area 810/13, and at the VDMA Biomass and Minerals

Practice Days:

Terminator Type V-Single-shaft shredder for

pre-shredding

Metalfex - Nonferrous metal separator

Axtor 4510 - Universal shredder

Nemus 3000 - Drum screen

Crambo direct - Dual-shaft shredder

Multistar One - Star screen with overlength return

And not forgetting the new Connect! condition monitoring tool.