New project to recycle electric scooters and bikes – ensuring sufficient supply of valuable metals

15.01.2024Electric scooters and e-bikes will be better recycled in the future as the Department of Chemistry at the University of Jyväskylä and the Finnish Environment Institute (Syke) in Finland jointly develop new solutions for recovering valuable metals.

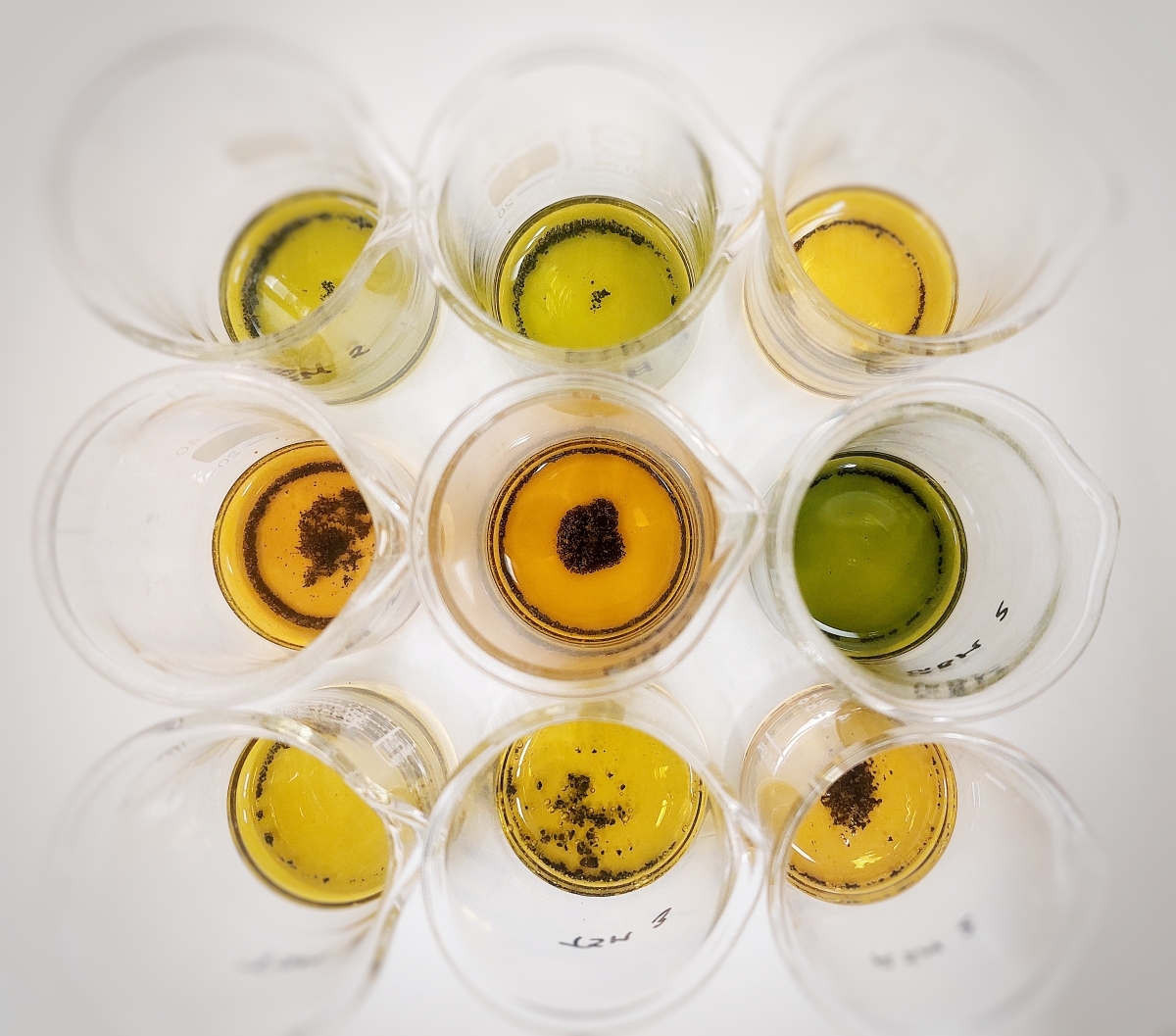

The UC-Mobility project will provide innovative technological solutions to recover critical raw materials from the micro-e-mobility waste fractions, e.g. used e-bikes and e-scooters. The picture shows how magnetic samples dissolving in the aqua regia

The UC-Mobility project will provide innovative technological solutions to recover critical raw materials from the micro-e-mobility waste fractions, e.g. used e-bikes and e-scooters. The picture shows how magnetic samples dissolving in the aqua regia

© Finnish Environmental Institute

Last spring, the Department of Chemistry at the University of Jyväskylä (Finland) and the Finnish Environmental Institute launched a joint UC-Mobility project to develop new technological solutions for recovering critical raw materials from end-of-life electric scooters and electronic bikes.

Critical metals such as cobalt and neodymium are recovered from waste fractions using 3D printed scavenger technology developed at the University of Jyväskylä. This technology offers the capability to selectively separate critical and commercially valuable metals that can be reused, says Siiri Perämäki, Senior Lecturer at the Department of Chemistry.

Samples of electric micromobility vehicles have already been acquired and dismantled. They are currently undergoing elemental analysis. The project will also involve piloting the developed technology on a larger scale and assessing the life-cycle impacts of the developed technology.

By conducting trials on a larger scale, around five litres, we will get a better idea of how the recovery process works and how it can be scaled up to a larger processing plant, explains Perämäki.

Ensuring the future supply of electric micromobility

The Finnish Environmental Institute will assess the life-cycle impacts of electric micromobility and the 3D printed scavenger technology developed by the University of Jyväskylä and review the regulation of micromobility and its waste fractions. In addition, the Finnish Environmental Institute will estimate the stocks of electric micromobility vehicles and their future material needs.

Based on the results of the project, recommendations will be made for better management of waste fractions from electric micromobility and for the recovery of critical raw materials from the fractions, explains Emilia Suomalainen, Leading Researcher at the Finnish Environmental Institute.

The three-year UC-Mobility project started on 1 March 2023 and has received € 896 500 in funding from Business Finland.

More information about the UC-Mobility project you can find here.