Endless possibilities for enhancing filter efficiency take centre stage at FILTECH 2024

22.01.2025Advanced air and water filtration systems meeting the stringent safety standards of major industries such as food and beverage processing and mining and mineral extraction were comprehensively showcased by 590+ Exhibitors at the recent FILTECH 2024 exhibition and conference held in Cologne/Germany.

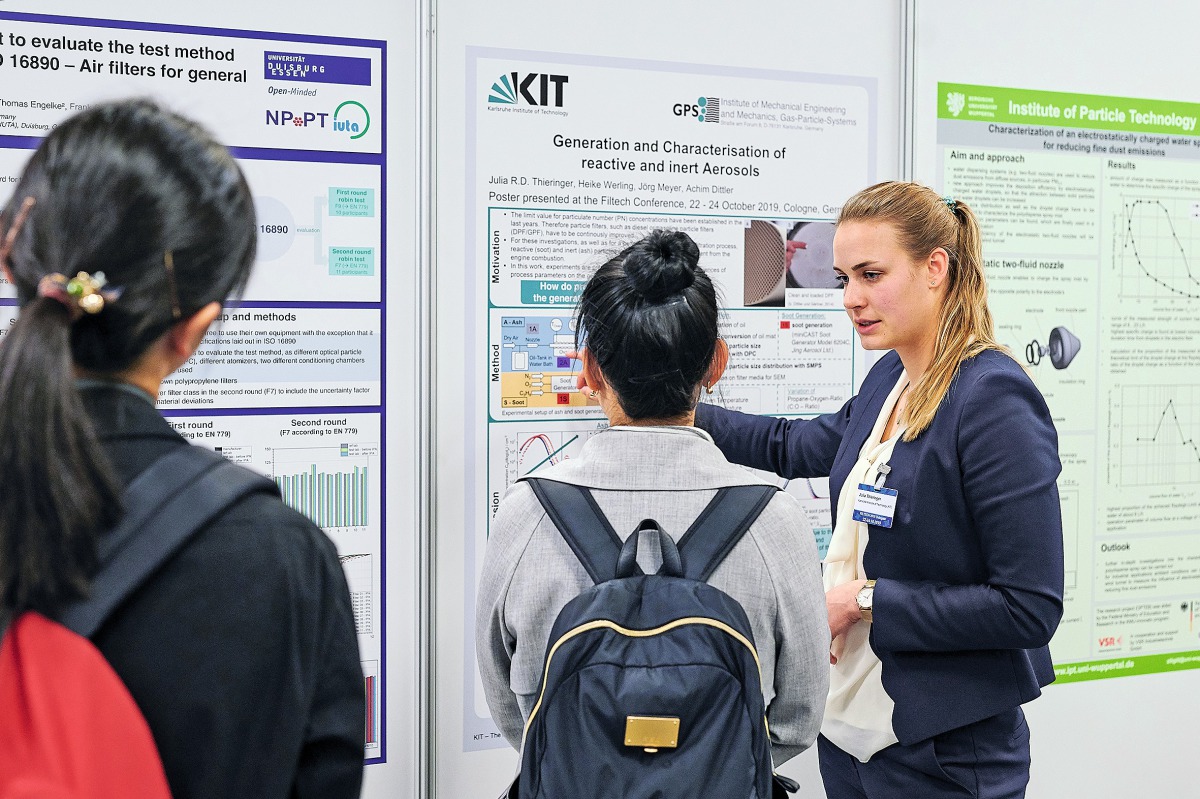

© Filtech

© Filtech

In mining operations meanwhile, there are equally stringent regulations applying to the control of dust, wastewater and other emissions which are being met by effective filter systems. Significant amounts of water are used for mineral processing and the separation of solids from liquids enables the reuse of water, reducing consumption and lowering environmental impact.

Hazardous tailings – the waste material left after extracting minerals – are also effectively dewatered with the huge automated filter presses engineered by leading FILTECH exhibitors such as Andritz, Diemme and Metso, further cutting waste and preventing the formation of tailings ponds which can pose environmental and safety risks.

During mineral processing, filtration systems also ensure high product purity by removing unwanted solids, improving both product quality and market value. The recovery of fine particles of valuable minerals that might otherwise be lost is another key benefit.

International presence

FILTECH 2024 set new attendance records, with over 590 exhibitors taking part and 61% of visitors from outside Germany, with a notable increase in international guests from North Africa, South America and the Middle East, as well as the established hubs in Europe, the USA and Asia.

In parallel, over 200 lectures were presented at the FILTECH 2024 conference covering all aspects of the far-ranging filtration industry.

In essence, optimising the efficiency of woven or nonwoven filter media is all about achieving the perfect balance between the material’s capacity to capture and hold dust or other particles and its pressure drop – its resistance to the air, liquid or gas that is being passed through it.

There are of course, many parameters that can influence this – as well as a potentially endless range of potential fabric constructions – and intensive research and trials continue to be undertaken with the aim of optimising this balance, which is always the underlying theme of the FILTECH conference. At the 2024 event, many forward-looking new concepts for optimising filter efficiency – from the customisation of high performance membranes at the nanoscale to the adoption of AI and digital twins – were introduced to delegates.

Media trends

In terms of filter media trends, it was particularly notable at FILTECH 2024 that the integration of nanofibre particles and webs into nonwovens is gaining increasing importance and the accommodation of sustainable raw materials as an alternative to synthetics was another key theme.

Linking the two together, leading manufacturers of nanofibre production technology such as Elmarco and Invenso and their customers are widely exploring the introduction of renewable feedstocks and environmentally friendly solvents in the production of electrospun nanofibres.

Promising new feedstock candidates include PETG – a cost-effective polyester derivative as an eco-friendly alternative to PET which eliminates the need for processing with fluorinated solvents – as well as polylactic acid (PLA) and polycaprolactone (PL). Natural cellulose is also now being electrospun into ultrafine fibres as small as 300nm, possessing low thermal expansion while remaining lightweight yet strong. Chitosan is another bio-based polymer with excellent water uptake properties being used to form hydrogels.

Green solvents are also being developed to replace toxic substances or those derived from petrochemicals in electrospinning.

Faster pleating

In another notable trend, filter media pleating – a process unique to this industry – is becoming ever more widely adopted as technology suppliers increase performance speeds.

Through pleating, filters can offer increased surface area and density without impacting airflow, enabling more particles to be collected without increasing pressure drop or energy consumption.

The developers of pleating technology such as Switzerland’s JCEM, Germany’s Roth Composite Machinery and India’s A2Z Technologies are continuing to enhance their machines and at FILTECH 2024 models were demonstrated inserting pleats with depths of between 24 to 40 mm into nonwoven filters at speeds of over 500 per minute.

Constant innovation

“At successive FILTECH exhibitions and conferences, I continue to be constantly amazed at the sheer diversity of applications for filter systems and the successive innovations that arise from the intensive R&D that’s behind this industry,” says Suzanne Abetz, FILTECH managing director. “Major new markets for effective filtration in such areas as the electrification of vehicles, hydrogen transportation and storage and carbon capture mean the industry is continuing to drive and expand technology options, and if you’re involved at any stage in this supply chain, FILTECH exhibitions and conferences are the place to be.

You are welcome to join us at our next combined exhibition and conference which takes place in Cologne from 30 June to 2 July 2026!”