Bulk Handling Systems to build patented Autonomous-Container-Loop facility for Grand Junction, CO (USA) to be operated by Bruin Waste

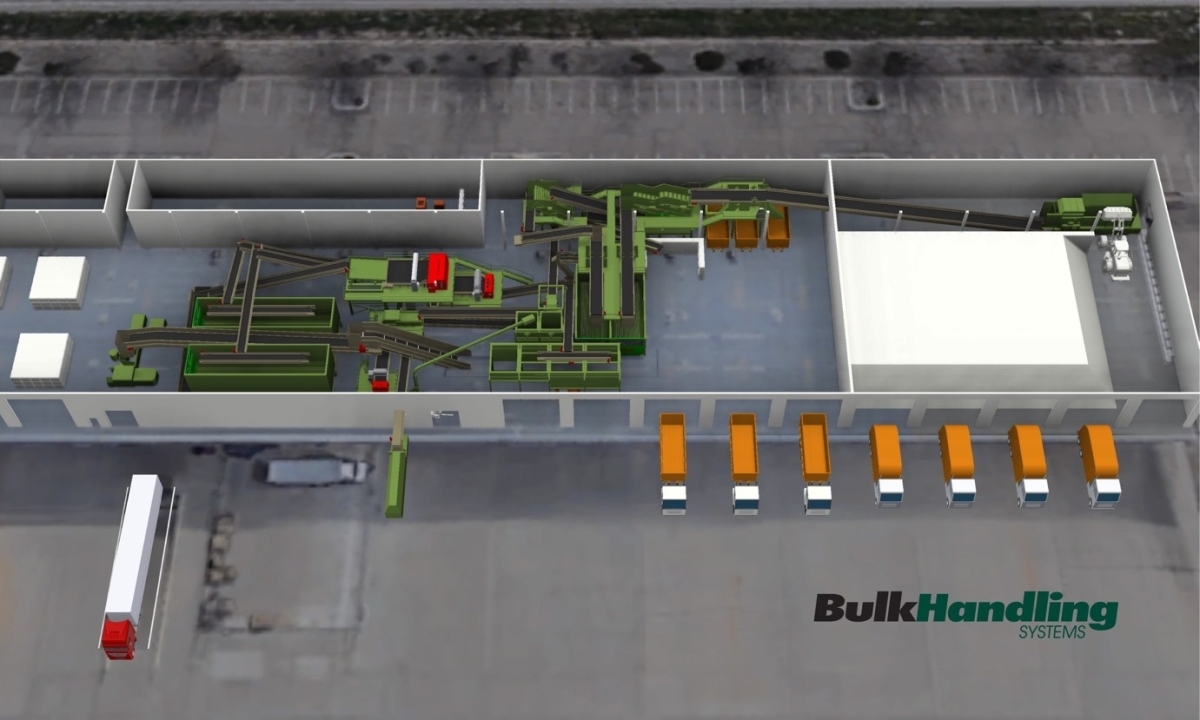

02.10.2025Bulk Handling Systems (BHS), one of the global leaders in advanced recycling and waste processing systems, announced its project in Grand Junction Colorado (USA); to be run by Bruin Waste, a long-time waste disposal leader in the western Colorado region. The new facility represents BHS’ third Patented Autonomous-Container-Loop system to be deployed.

© Bulk Handling Systems

© Bulk Handling Systems

The Grand Junction project supports the City’s long-term sustainability goals through:

- BHS' patented Autonomous-Container-Loop which provides full commodity recovery and high-purity on plastics and aluminum containers with no manual labor.

- 12 t/h highly automated Dry Mixed Recycling (DMR); utilizing state of the art AI and controls to minimize labor at key areas, while maximizing recovery and commodity purity.

- Multiple AI detection points provide material composition and performance data throughout the ystem, integrating this information into the main system controls and reporting platform in real time.

- The only automated MRF on the Western Colorado slope. Puts Grand Junction on par with the largest North American metropolitan areas in the recycling space.

Key technologies and features

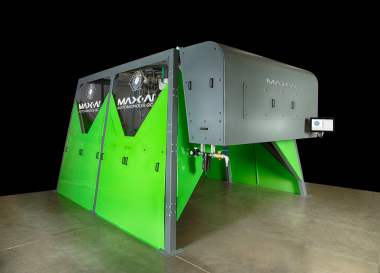

- Max-AI® AIR: An innovative sorting solution that combines artificial intelligence (AI) with high-speed air ejection to accurately separate recyclables to reduce reliance on manual sorting.

- SpydIR®-HS: A high-resolution optical sorter using Hyper Spectral Imaging to identify and separate a wide range of materials with exceptional precision.

- Total Intelligence Platform (T.I.P.): Provides real-time monitoring and analytics of material composition and system performance, enabling data-driven decision-making.

- BHS Debris Roll Screen® and Polishing Screen®: Patented “NO-WRAP” screening technologies that efficiently separate materials based on size and shape.

“We are excited to be working with BHS to build a state-of-the-art Materials Recovery Facility (MRF) in Grand Junction, Colorado. This exciting project marks a major investment in the future of recycling for the Western Slope and surrounding communities. Set to be fully operational by June 2026, the Grand Junction MRF will dramatically increase local capacity to sort and process recyclable materials using cutting-edge AI technology allowing for a fully autonomous container recovery. We believe this project represents an important step forward in bringing the most advanced recycling technologies and automation to smaller communities where currently none exist, while supporting future EPR legislation,” says Jeffrey R. Kendall, CEO Bruin Waste

BHS continues to partner with organizations and communities focused on sustainability. Their development of the Community-Recycling-System is fast becoming the standard, allowing small to mid-sized municipalities of all sizes to preserve critical landfill capacity and maintain low-cost disposal access for their regions.