TOMRA sorting recycling introduces AUTOSORT COLOR

TOMRA Sorting Recycling has introduced AUTOSORT COLOR, a new machine which works in combination with AUTOSORT LASER to separate glass from municipal solid waste with high effectiveness. AUTOSORT COLOR achieves purity rates greater than 95 % at high throughput rates, even when input materials are wet, dusty or dirty.

AUTOSORT COLOR will enable sorting operations to extract and sell this glass, which would otherwise fail to make it through to the recycling process. AUTOSORT COLOR also helps sorting businesses minimize the risks of disruption, downtime and repair costs arising from damage to components in sorting machines not intended for glass.

AUTOSORT COLOR additionally enables financial savings downstream of the sorting process, because household waste containing glass can result in higher incineration costs. Extracting more glass from MSW will also reduce landfill costs.

Valerio Sama, Vice President and Head of Product Management Recycling, commented: “In most nations across the world, there is significant room for improvement in the recovery of glass from household and business waste. Separating more glass for recycling is better for the environment and better for sorting businesses’ profitability, and with AUTOSORT COLOR both of those benefits are now achievable.”

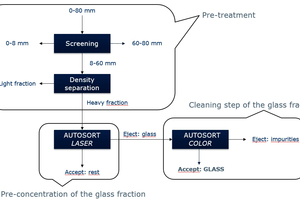

In developing AUTOSORT COLOR, TOMRA set industry standard-setting goals of recovering a minimum of 80 % of glass from MSW, with at least 95 % of the recovered glass of saleable quality. The first step in the process of removing glass from MSW is pre-treatment. After the MSW passes through a bag opener, conventionally the fine fraction (0-80 mm) is screened-out. This fraction is then split into three categories by a double-deck vibrating screen: fine fractions of 0-8 mm diameter, such as organic waste and sand, a middle fraction of 8-60 mm and an oversize fraction of 60-80 mm.

In the second step, the middle fractions, which contain the highest glass content, are subjected to density separation. This removes the lighter fractions and sends the heavier fractions to the AUTOSORT LASER unit. Here a combination of laser (LAS) and near-infrared (NIR) detection technologies enables the separation of glass from the rest of the materials.

In the third and final step of the process, the innovative AUTOSORT COLOR machine classifies the glass fractions with a high-performance camera and separates any remaining impurities from the higher-quality glass. The result is the recovery of resaleable glass with a consistently high purity of more than 95 %.