TOMRA Sorting Recycling hosts global conference to focus on recycling plastics

Industry leaders share knowledge on solutions for tackling plastic waste and conference guests see TOMRA’s recycling technologies in action.

This was the third biannual TOMRA Leads Global Conference, an event designed to share knowledge and accelerate progress in recycling and waste management through keynote speeches, presentations, discussions, and networking opportunities. The plant visit was made to Integra Plastics in the town of Elin Pelin, just outside the capital city.

Tom Eng, Senior Vice-President and Head of TOMRA Sorting Recycling, commented: “The TOMRA Leads Global Conferences are proving to be a useful and popular forum for the exchange of information and ideas. The focus of this year’s event was something which deeply concerns hundreds of millions of people all over the world: what can be done to tackle the discarded plastic piling up at landfill sites, drifting in oceans, and killing marine life. The conference showed how recycling plastic waste has a vital role to play – and how, at the same time as benefiting the environment, this is also a commercial opportunity. Waste can be valuable.”

Expert insights into a wide range of issues

On the second day of the conference, high-caliber speakers shared expert insights into the direction of the recycling market, the circular economy and the role of virgin materials, and financial investment models. Tom Eng opened this part of the conference with a welcome speech titled “The future of recycling – are you ready?” Many answers to that question were given in the presentations and panel discussions which followed.

Five presentations were made during the morning. Dr Volker Rehrmann, Executive Vice-President and Head of Circular Economy at TOMRA, shared TOMRA’s perspective on the circular economy and the role TOMRA will play. Andy Grant, Technical Director- Local Government of Eunomia Research & Consulting, talked about waste collection systems and the impact on recycling plastics. Herman Van Roost, Business Development Manager Recycling, TOTAL Refining & Petrochemicals, gave a presentation on circular plastics’ fundamentals and innovation challenges. Professor Ed Kosior, Managing Director at the consultancy Nextek, talked about the recyclability of plastics. And Iilya Kardashliev, Principal Banker in the Infrastructure Department at the European Bank for Reconstruction and Development, explained financial models to support plastic recycling investments.

In the afternoon, visitors had the choice of attending either the Plastic Recycling conference or the Legislation conference, which ran at the same time. Both conferences were followed by panel discussions.

One discussion focused on overcoming challenges in the plastics value chain. This was opened by László Székely, Head of New Plastics Economy at TOMRA, before a case study of a converter’s requirements was given by Graeme Smith, Innovation and Sustainability Manager at the packaging and paper specialists Mondi Group. This was followed by the one-hour discussion, which involved László Székely, Herman Van Roost, Volker Rehrmann, Ed Kosior, and Graeme Smith, and was chaired by Jim Keefe, Group Publisher at Recycling Today.

The other discussion exchanged information and ideas on how recycling and waste management businesses must respond to changing regulations. To set the scene, Tina Adjic, a senior consultant with ADSinsight, provided an update on EU legislation on waste. To give an overview of the current state of affairs, Fabrizio Radice, Vice-President Global Sales & Marketing at TOMRA Sorting Recycling, reviewed what is actually being recycled at present, how new legislation will affect current practices, and what will be required of new designs from packaging manufacturers. Aligning legislation and business was examined further during the discussion, which involved Andy Grant, Tina Adjic, Fabrizio Radice, and Roland Ramusch, and was chaired by TOMRA’s Vice-President of Governmental Affairs, Thomas Morgenstern.

Finally, conference visitors were given a vivid reminder of the importance of the circular economy when Kristine Berg, Circular Economy Advisor at TOMRA, introduced a video about eXxpedition, the 2018 sailing expedition which featured an all-woman crew. This showed with shocking clarity why the vast stretch of ocean traversed by the expedition is known as the Great Pacific Garbage Patch (http://video.tomra.com/exxpedition-the-great-pacific-garbage-patch).

Plant visit shows TOMRA’s vital role

in the circular economy

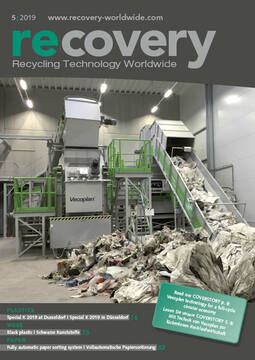

To see plastics recycling in action, conference delegates were given a tour of Integra Plastics’ new, € 40 m facilities on the outskirts of Sofia, which opened in February 2019. The new plant employs 85 people and 14 TOMRA AUTOSORT machines. One AUTOSORT is combined with the Laser Object Detection (LOD) system and two have been specially developed for this plant, to sort-out black flexible materials. There is input capacity here to recycle 40 000 tons of mixed-color post-consumer film annually.

Integra’s specialty is the production of top-quality recycled low-density polyethylene (LDPE), high-density polyethylene (PEHD), and polypropylene granules (PP). To see how this is achieved, conference delegates were shown Integra’s entire, start-to-finish process for plastic recycling.

This starts with the plastic waste arriving in bales, which are opened by a de-baling unit and cut by a large shredder. The shredded material moves along more than one kilometer of conveyor belts, where a magnet and a screen filter-out unwanted materials such as metals and other fine materials. Next, the material is sorted by TOMRA machines, if desired, into six streams, by polyolefin type and color, before the plastics are hot-washed. After washing and drying, the plastic flakes are finally cleaned of any remaining impurities, colors and/or materials through additional TOMRA units, before being forwarded for regranulation. This is when the plastics are compressed, melted, filtered, degassed, homogenized, and transformed into pellets. In the final stage the pellets are packed into one-tonne bags, ready for re-use in a wide range of applications. Integra is able to produce customized resin qualities , such as different material grades combined with different colors, making this plant unique and trend-setting.