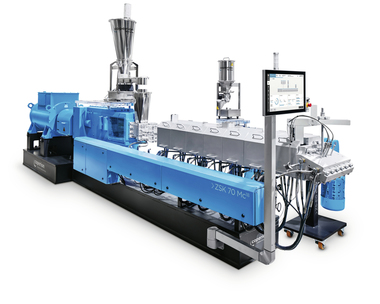

Third extrusion line installed

“The demand for recycled plastics is continuously rising. In order to serve our customers with the required quantities, we must accelerate our recycling activities. With Texplast as our partner, we have access to high-quality recycling material on the German market,“ says Georg Lässer, Head of Recycling at ALPLA. „In addition, we secure our expertise and experience in the logistics sector and use the existing network linking the food retailing industry.“

Using the shortest route and optimized logistics, Texplast transports the returnable bottles - valuable recycling material - to the recycling plant, thus keeping the carbon footprint as small as possible, as Matthias Schäfer, authorized representative at Texplast emphasizes. „The cooperation with ALPLA closes the bottle cycle: we recycle the returnable goods from the food retail trade and turn them into high-quality, food-grade regranulate, which ALPLA uses to manufacture preforms for new PET beverage bottles. The colorful flakes arising in the process are used by FROMM for their own strap production.“

//www.alpla.com" target="_blank" >www.alpla.com:www.alpla.com

//www.texplast.de" target="_blank" >www.texplast.de:www.texplast.de