Synergies leveraged: Eggersmann constructs disposal centre in Poland

The starting signal resounded on 11 January 2013, when Jacek Połomka, CEO of Zakład Zagospodarowania Odpadów Sp. z o.o., and Karlgünter Eggersmann, head of the Eggersmann Group, signed the contract for the construction of a plant for mechanical-biological waste treatment (MBT) in Marszów, near Zary, Poland.

The scope of the contract included both engineering, implementation planning, procurement, production and supply of machinery and conveying/ handling systems, and installation, start-up, trial operation and turnkey handover of the plant, plus all the civil-engineering for the project. All work – from placement of the order to handover – was completed within the agreed two-year period, with the happy result that the Marszów MBT has now been successfully operating since January 2015. Eggersmann was also responsible for obtainment of the necessary operating permit

“We handed over the disposal center in Marszów to the customer as a turnkey plant completely ready for operation, Zakład Zagospodarowania Odpadów Sp. z o. o. only had to provide the necessary staff ”, notes Waldemar Witkowski, head of Eggersmann Anlagenbau Kompoferm Polska. “And not only that, of course, we also guarantee comprehensive support, even after handover”.

The aims of this plant - and of mechanical-biological waste treatment in general – are the separation of the useful materials (“recyclables”) contained in such waste for subsequent re-use, the recovery of refuse derived fuels (RDF), and processing of the organic fraction in accordance with specific national requirements concerning the preconditions for landfill disposal. The plant, designed for an annual capacity of around 72 000 t of waste, will now process municipal solid waste (MSW) and commercial and industrial (C&I) waste from the twenty-two surrounding municipalities and their approx. 200 000 inhabitants. This form of reduction of the material mass makes it possible to significantly decrease the volume of matter routed to landfills. A great advance, indeed - prior to the construction of this mechanical-biological treatment plant, all waste was landfill dumped without treatment. The available knowledge concerning waste avoidance, recovery of useful materials and recycling is now also passed on to children and adults at regular intervals in a seminar room located on the plant site.

A special feature of the Marszów MBT project was the unusual location of the construction site, which is situated between the neighboring towns of Zary and Zaga ´ n and was formerly completely wooded; there was not even an access road. A beneficial factor here was that the Eggersmann Group not only possesses extensive plant-engineering capabilities, but is equally qualified as a specialist in civil-engineering. Eggersmann was thus responsible for development of the approx. 11 hectare site, including planning and the construction of roads and paths, and also for connection to water and electricity supplies. In addition, the company built all the structures located on the site, such as industrial, administrative and service buildings, etc., and also created the landfill.

For the mechanical treatment section, Eggersmann supplied and installed the structural steel, machine and handling/conveying systems, tunnel feed and discharge systems, screen drums, optical separator system (near-infrared technology), ferrous and nonferrous metal separators, pre- and secondary shredders, baling presses and enclosed sorting lines. BRT, an Eggersmann Group company, supplied the SCHLITZ-O-MAT, an opening system for plastic bags filled with all types of waste and recyclables, and the DRUM-O-MAT, which classifies the material input into a range of different particle-size fractions by means of screening drums.

The overall plant can be roughly subdivided into four sections: waste reception, mechanical sorting, intensive composting, and final composting. The incoming material is stored in the hall for incoming materials, roughly sorted into domestic refuse and commercial/industrial waste. Depending on the processing line currently operating, the corresponding material is routed to the bag opener before being separated into various fractions, of 0–80 mm, 80–240 mm and > 240 mm, by means of a screening drum.

The large-particle fraction is passing directly to manual sorting, in order that recyclables still contained in it can immediately be filtered out. The medium-sized fraction is further processed using ferrous and nonferrous separators, optical separator systems, a ballistic separator from Hartner (a company now also part of the Eggersmann Group), and in part by means of manual final processing on enclosed sorting lines. In this way, mixed plastics, cardboard, films, rigid plastics, ferrous and non-ferrous metals, and also PET (sorted by colour), are recovered as recyclables and can be returned to economic use in industry.

The 0-80 mm fraction screened out contains the major portion of the substances still biologically active and is routed to rotting via a fully automated feed system. The biological-treatment sector features a total of seven rotting tunnels. The material is injected with process water, further diluted with water, and then held at temperatures of 50 to 60 °C for around three weeks. The material is also simultaneously aerated by means of fans. The necessary air is drawn out via a corresponding installation on the rear wall of the tunnel, and returned in part to the process (recirculating air system). The waste-air is cleaned in a scrubber and on a biological filter before being discharged to the atmosphere. Biological degradation simultaneously reduces the organic-substance content.

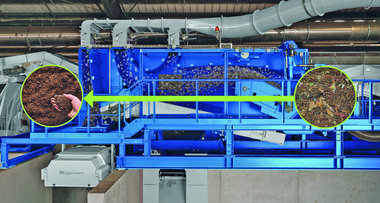

After being held in the intensive rotting for three weeks, the material spends another six weeks on the post-rotting bed. Here, the BACKHUS 17.55 turner with a hose reel, supplied by the Eggersmann Group company BACKHUS, assures, inter alia, more rapid composting and stabilization, plus reliable disinfection of the fractions. The material is then again screened on a mobile unit, to obtain a material fraction suitable for landfill dumping. Lightweight material is then pneumatically removed on an air separator and added to the RDF. The heavier material goes to the landfill.

The landfill also located on the site is divided in two, and has its own water-storage system. As long as one section of the landfill is not being used, it serves as a rainwater reservoir, and the water can be used by the fire-brigade for fire-fighting. There is also a process water reservoir. The seepage water (“leachate”) is also collected and routed to the intensive composting process. Surplus leachate is fed directly to the water treatment plant. “Marszów is one of the major projects for which we leveraged all the synergies available within the Eggersmann Group and have managed, with our know-how in a whole range of fields, to achieve a more than satisfactory result”; Waldemar Witkowski affirms. “The Polish market has continued to be of very great interest for us since the completion of the Marszów disposal center, it was followed up by projects in Poznan, Gdansk and Grudziadz, for example”. On the occasion of the commissioning of the new plant the editors of magazine recovery took the opportunity to ask questions to Jacek Połomka, President of the Supervisory Board of ZZO Marszów:

recovery: What was the reason for constructing this recycling plant at this time and at this location?

Jacek Połomka: It became necessary to construct a regional facility for the processing of municipal waste at Marszów as a result of the municipalities’ need to meet the recovery and recycling levels stipulated in accordance with Poland’s EU obligations. Under the new waste-management system, which has been in force in Poland since 1 July 2013, the local authorities (i.e. the municipalities) are responsible for the correct functioning of the system. The initiators for the construction of the Marszów MBT were fifteen municipalities from the Lebus Voivodeship (county), which are part of the Łuzycki municipal alliance. These municipalities founded Zakład Zagospodarowania Odpadów Sp. z o.o. and commissioned it to construct and operate the Marszów plant. The plant was built incorporating the best available technologies and meets all environmental requirements deriving from both European and Polish legislation. The decision to build the MBT in Marszów was taken on logistical criteria. This is the optimum location for the two largest municipalities, Zary and Zagan. The Marszów MBT is situated between these two towns, close to Highway 12, and in a wooded terrain, well away from buildings.

recovery: What special features and challenges were there during the construction phase? Are there any plant-engineering solutions specifically tailored to this plant?

Jacek Połomka: The solutions applied in the plant have been adapted to the facility’s special features: their scale, the volume of waste treated, etc.

recovery: Why did you choose the Eggersmann Group as the prime contractor?

Jacek Połomka: The Eggersmann Group submitted the best bid in the public-tendering procedure, under the title: “Design and construction of a waste recycling plant”. This bid was selected in accordance with the requirements of [Polish] open-tendering regulations.

recovery: The new recycling plant at Zary has been in operation since the beginning of 2015 - what have been the operating results and experience with the new plant up to now?

Jacek Połomka: The plant operates trouble-free. The technology conceived makes it possible to achieve the necessary level of recovery and recycling of waste products, and to reduce the quantity of biologically degradable waste routed to the landfill.

recovery: How do you estimate the future development of the recycling industry in Poland?

Jacek Połomka: Waste management will continue to develop in Poland in line with the EU requirements. It will progress toward reduction of the waste produced, an increase in the recycling of waste products, and a decrease in the landfill disposal of the biologically degradable fraction. The Eggersmann Group is an alliance of independent companies consisting of twenty-four nationally and/or internationally active firms, with four foreign branches in Poland, the UK, France and Iraq. In addition to activities in the fields of civil-engineering, property/facility management and plant-engineering, this all-rounder’s portfolio also includes the operation of composting plants.