Modular overband magnet for mobile recycling systems

At IFAT in Munich Goudsmit Magnetics from Waalre/The Netherlands will show their recently developed range of mobile overband magnets. The modularly designed magnets remove iron particles from underlying material streams and are intended for mobile recycling systems such as shredders, crushers and screens.

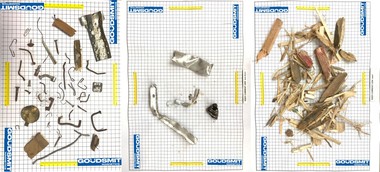

The magnetic separators are constructed with either Ferrite or Neodymium magnets, with the latter being upgraded from a 2-pole to a 3-pole system. This modified design provides a stronger magnetic field from the same number of magnets. The compact and strong Neodymium 3-pole overband allows iron to rotate more and pulls it loose, even when it is under a pile of material. This ultimately results in a cleaner product and allows more metal to be recovered.

Modular construction

The recent design of the mobile overband magnets is modular and includes an extra attenuator at the end of the magnet. As mobile crushers have a diverse power supply – electric or hydro – the modular construction offers the user a choice between a hydro drive, gearmotor drive or drummotor drive. The weakening magnet in the new version comes on top of the various working widths, available in 650, 800, 1000, 1200 and 1400 mm. This additional magnet carries the material further outside the conveyor belt and ensures a better shedding of the attracted iron parts. It also significantly reduces belt wear. An additional advantage of the Neodymium magnets is that the low weight of the magnet increases the mobility of the shredder or crushing unit.

Improved shielding

Both the magnetic field and the shafts and bearings are better protected in the new design. The magnetic field no longer radiates outside the side of the magnet, so the overband is better protected against contamination. Less iron sticks to the outside of the construction, saving cleaning time and maintenance. A protective cover on shafts and bearings prevents metal parts such as iron wire from wrapping around the shaft. The optimised shielding on the underside of the belt ensures that no iron parts can get between the belt and the magnet. Moreover, impact-reducing layers – placing an extra layer of rubber between the carriers – extends the life of the belt. The overband magnet also contains two central lubrication points, saving operators valuable time.

Goudsmit Magnetics has determined from customer inquiries that there is a greater need for better magnets for mobile crushing, screening and separation equipment. The 3-pole ferrite system has been used for overhead track magnets from the beginning, but has now been optimized for mobile applications. The 3-pole neodymium system is a completely new design and has been developed in series. Neodymium is stronger, ferrite is cheaper. Both magnet variants can be seen at the IFAT trade fair.

www.goudsmit.eu

Hall B6, Stand 316